Expressway guardrail

A highway and guardrail technology, applied to roads, roads, road signs, etc., can solve the problems of difficult repair, large deformation, lack of safety prompt function, etc., to achieve the effect of improving convenience, reducing the degree of deformation, and improving the efficiency of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

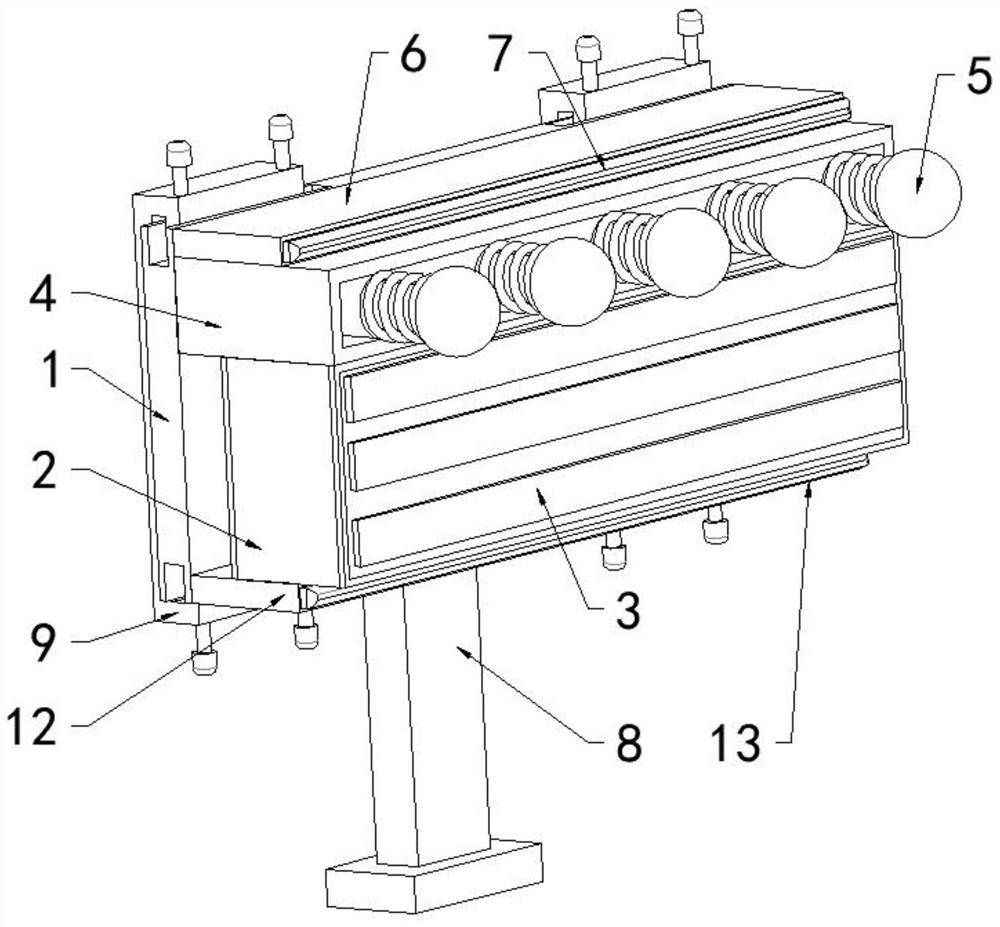

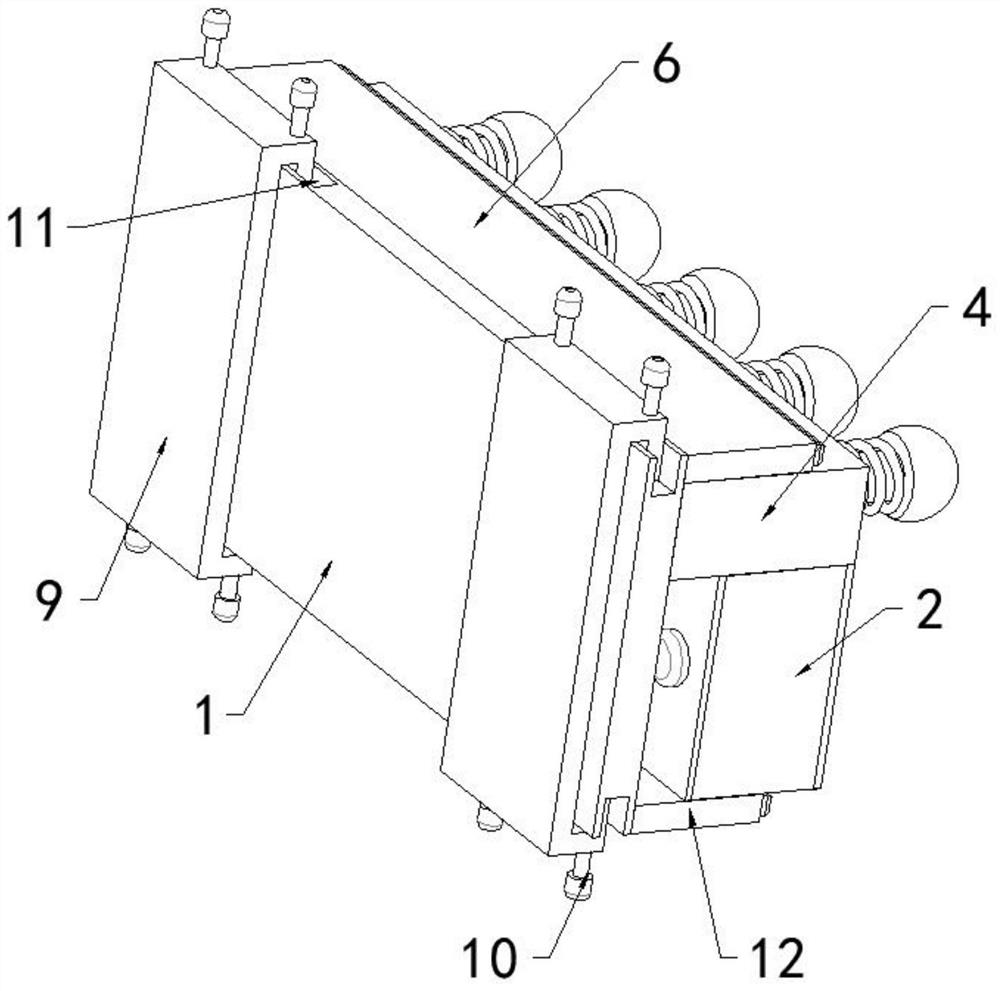

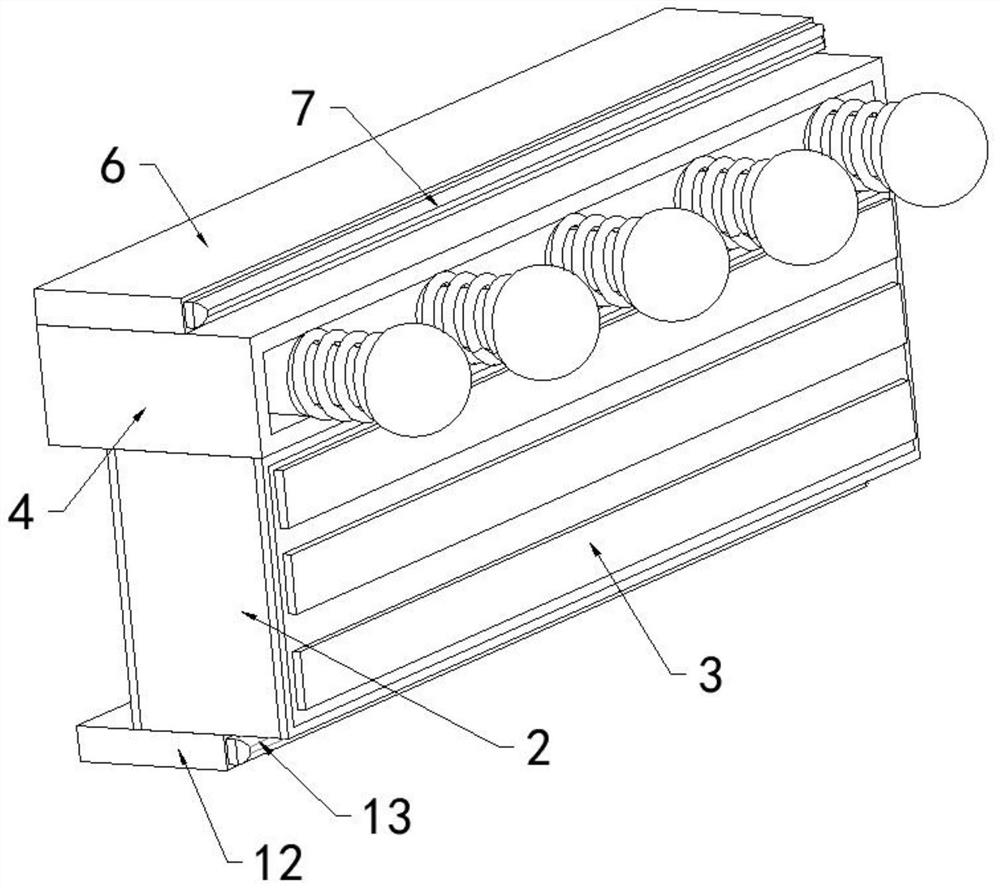

[0031] refer to Figure 1-7 , a highway guardrail, comprising a rear fence 1, a pillar 8 is installed on the rear end of the rear fence 1, and a first light box 6 and a control box 4 are detachably installed on the front end of the rear fence 1 from top to bottom , the electric control box 14 and the second light box 12, the front panel box 2 is detachably installed on the front surface of the electric control box 14, the front panel box 2 is provided with a reflective tape 3, and the front panel box 2 is filled with non-Newtonian Fluid, detachable installation between the first light box 6 and the control box 4, detachable installation between the control box 4 and the front board box 2, detachable connection between the front board box 2 and the second light box 12, after multiple groups The fence 1 can be detachably spliced into a road guardrail. The control circuit of the electric control box 14 includes the first light box 6 and the second light box 12 within three hund...

Embodiment 3

[0039] refer to Figure 1-7 , a highway guardrail, comprising a rear fence 1, a pillar 8 is installed on the rear end of the rear fence 1, and a first light box 6 and a control box 4 are detachably installed on the front end of the rear fence 1 from top to bottom , the electric control box 14 and the second light box 12, the front panel box 2 is detachably installed on the front surface of the electric control box 14, the front panel box 2 is provided with a reflective tape 3, and the front panel box 2 is filled with non-Newtonian Fluid, detachable installation between the first light box 6 and the control box 4, detachable installation between the control box 4 and the front board box 2, detachable connection between the front board box 2 and the second light box 12, after multiple groups The fence 1 can be detachably spliced into a road guardrail. The control circuit of the electric control box 14 includes the first light box 6 and the second light box 12 within three hund...

Embodiment 4

[0043] refer to Figure 1-7 , a highway guardrail, comprising a rear fence 1, a pillar 8 is installed on the rear end of the rear fence 1, and a first light box 6 and a control box 4 are detachably installed on the front end of the rear fence 1 from top to bottom , the electric control box 14 and the second light box 12, the front panel box 2 is detachably installed on the front surface of the electric control box 14, the front panel box 2 is provided with a reflective tape 3, and the front panel box 2 is filled with non-Newtonian Fluid, detachable installation between the first light box 6 and the control box 4, detachable installation between the control box 4 and the front board box 2, detachable connection between the front board box 2 and the second light box 12, after multiple groups The fence 1 can be detachably spliced into a road guardrail. The control circuit of the electric control box 14 includes the first light box 6 and the second light box 12 within three hund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com