Top-mounted ultralow-temperature butterfly valve capable of being overhauled on line

An ultra-low temperature, installed technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of reduced sealing effect, valve seal failure, and easy damage of the sealing ring, so as to improve the use performance, improve the sealing effect, high strength The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

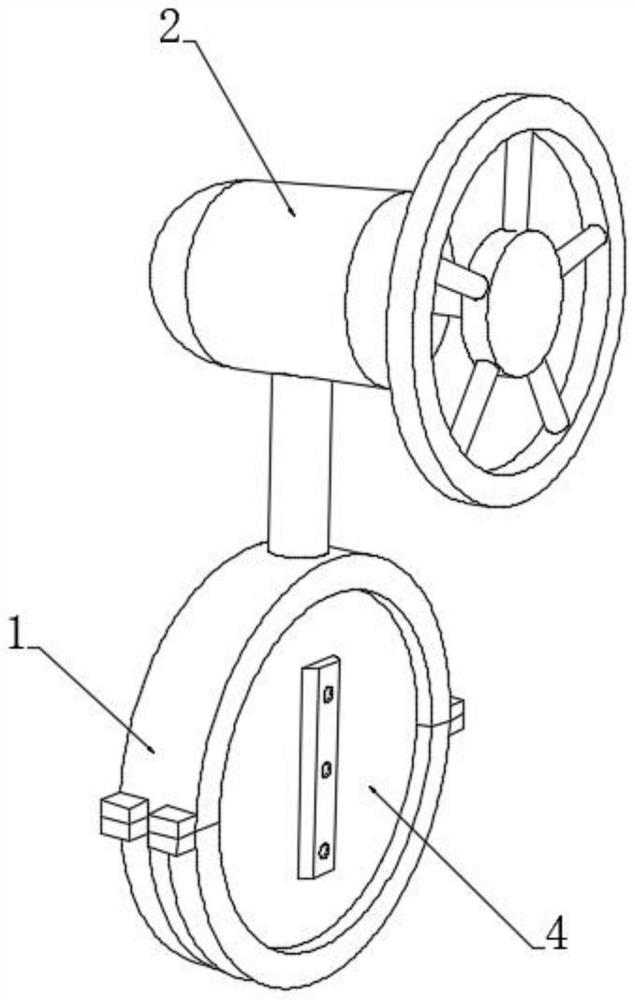

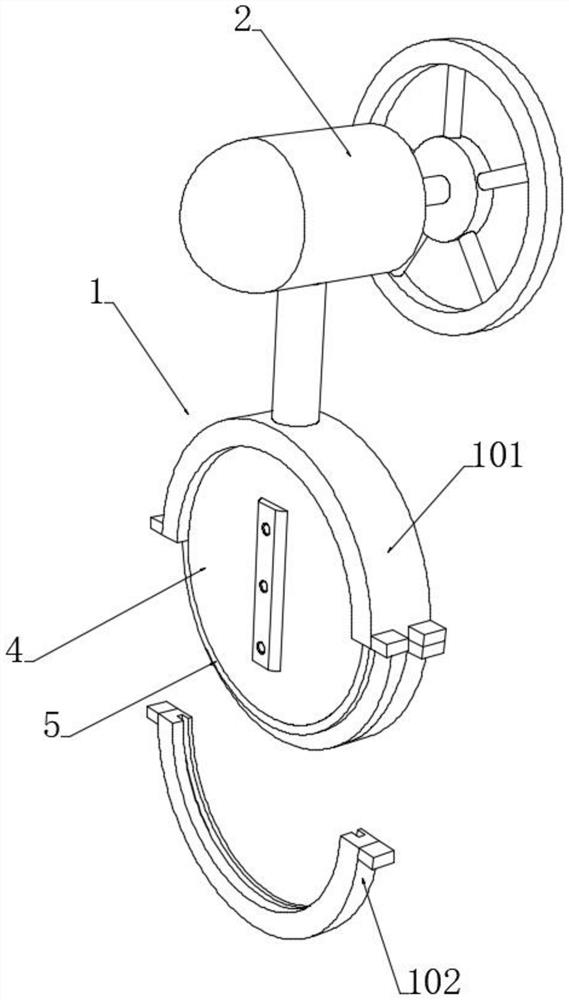

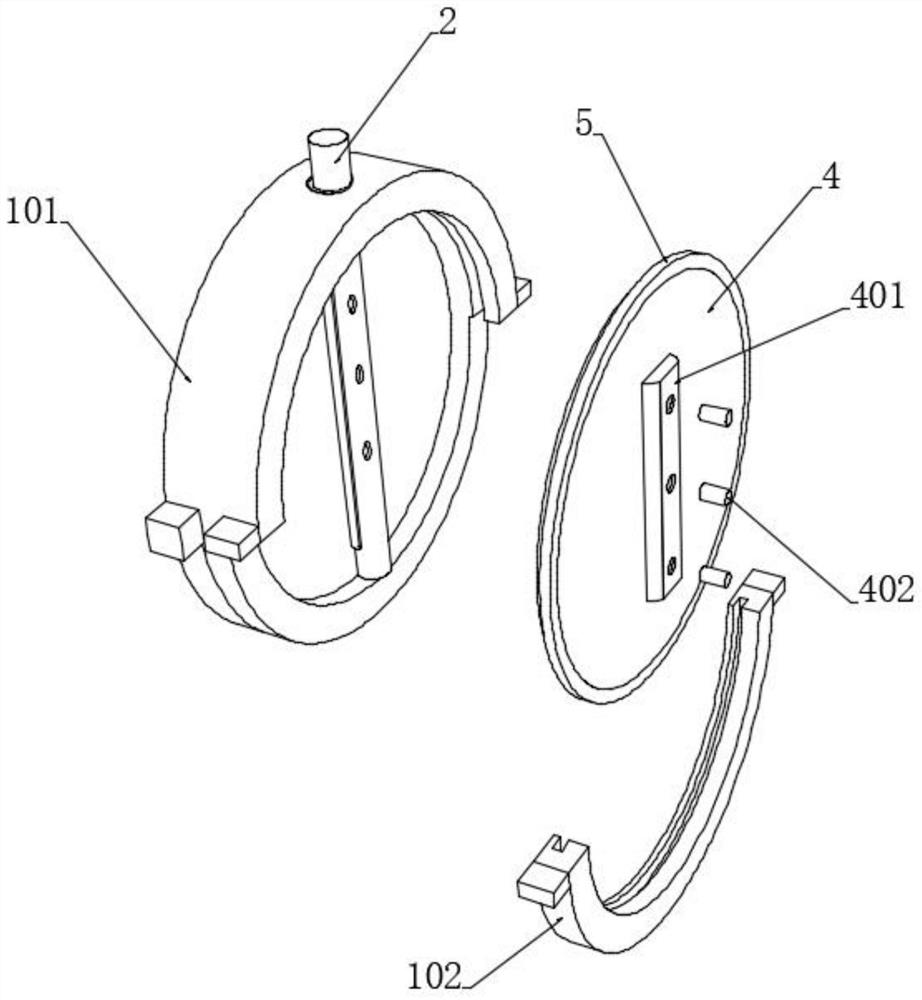

[0045] see Figure 1-7 , a top-mounted ultra-low temperature butterfly valve that can be repaired online, including a valve body 1 and a valve stem 3 rotatably installed in the valve body 1, and a valve cover 2 connected to the top of the valve stem 3 is installed on the valve body 1, and the valve cover 2 A turntable is provided on one side of the valve cover 2, and a drive structure to drive the rotation of the valve stem 3 is arranged inside the valve cover 2. The drive structure is connected with the turntable to realize the rotation of the valve stem 3 by operating the turntable. This is the prior art and will not be described here. To repeat too much, the valve body 1 includes a main valve body 101 and an auxiliary valve body 102 embedded on both sides of the bottom end of the main valve body 101. An arc-shaped embedded cavity is installed, and the valve stem 3 is fixedly installed with a valve plate 4 at the left and right ends of the valve body 1. The two valve plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com