Steel coil width and temperature measuring device on walking beam and working method thereof

A technology of temperature measurement and walking beam, which is applied in the direction of measuring devices, feedback control, instruments, etc. It can solve the problems of deviation of the center of gravity of the overflow coil, affect the production quality, and low production efficiency, so as to achieve a small and simple device and eliminate personnel. Ease of on-site operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose and technical solutions of the specific embodiments of the present invention clearer, the following will clearly and completely describe the technical solutions of the specific embodiments of the present invention in combination with the drawings and implementation examples of the specific embodiments of the present invention. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of the embodiments.

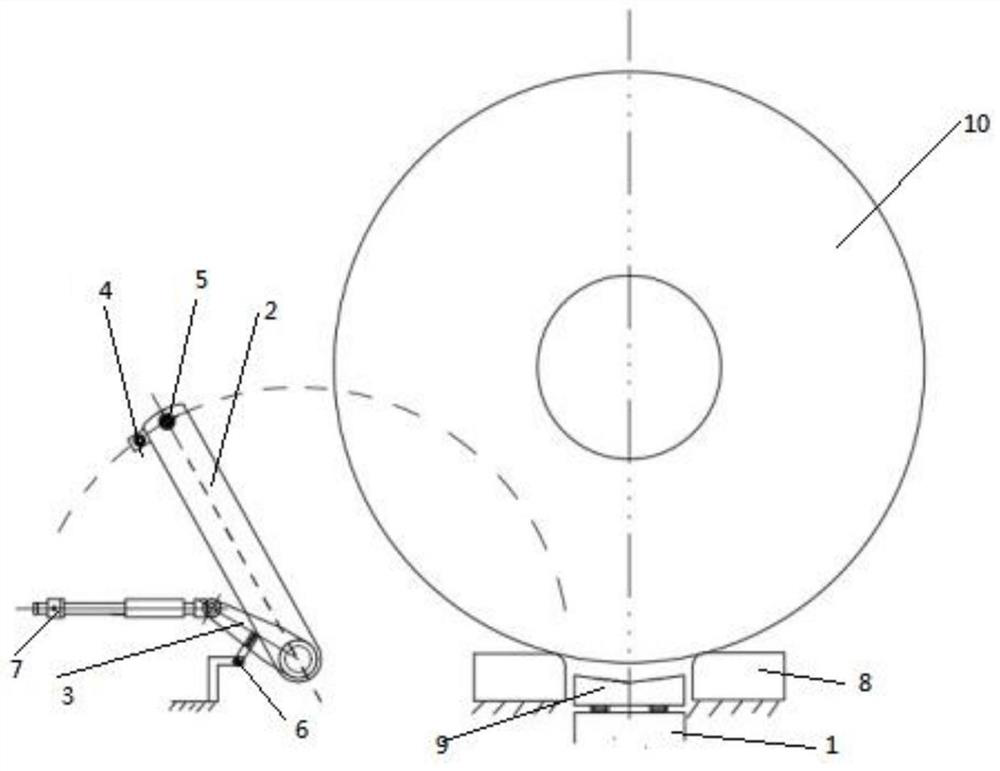

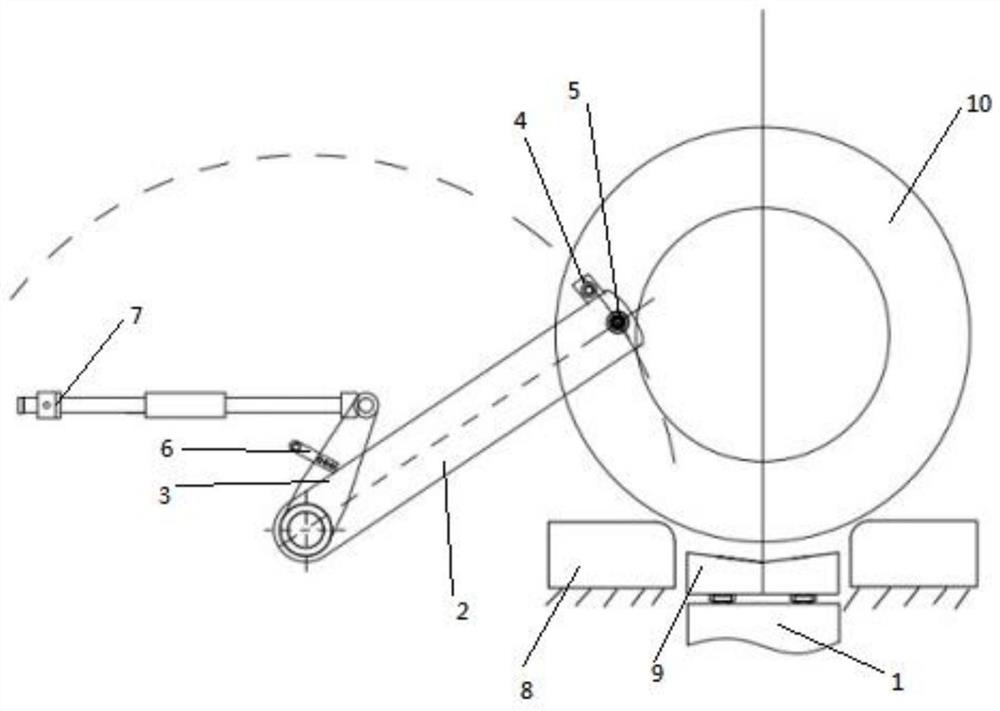

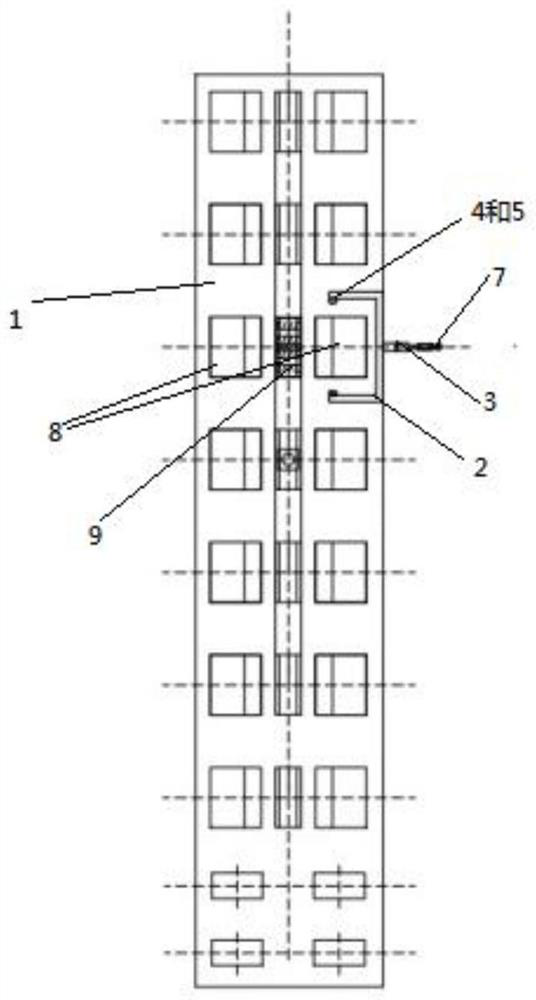

[0035] like Figure 1-4 As shown, a steel coil width and temperature measuring device on a walking beam includes a walking beam, and the steel coil width and temperature measuring device is installed on one side of the walking beam, including symmetrical swing arms, telescopic arms, temperature Sensors, ultrasonic sensors, position sensors and oil cylinders, the middle of the swing arm is pivotally connected to one end of the telescopic arm, the other end of the telescopic arm is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com