Low-temperature substrate heating table for growing semiconductor film and manufacturing method thereof

A heating stage, low-temperature technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the inability to achieve direct cooling of the substrate with a large source-substrate temperature difference, and the cracking and peeling of TFT circuit boards and films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

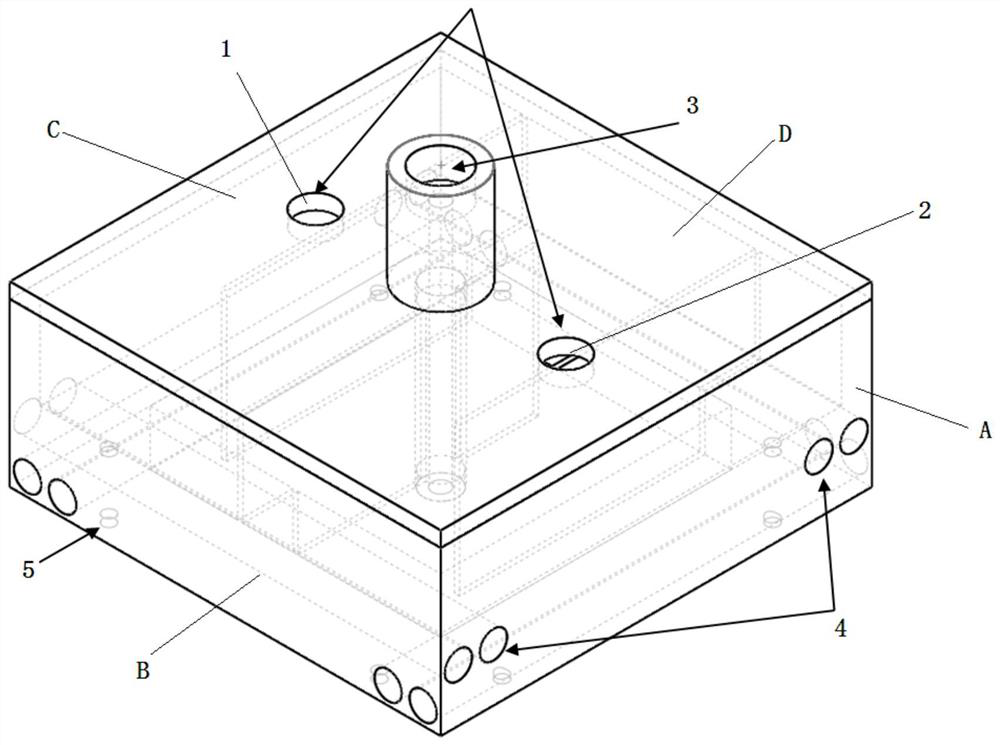

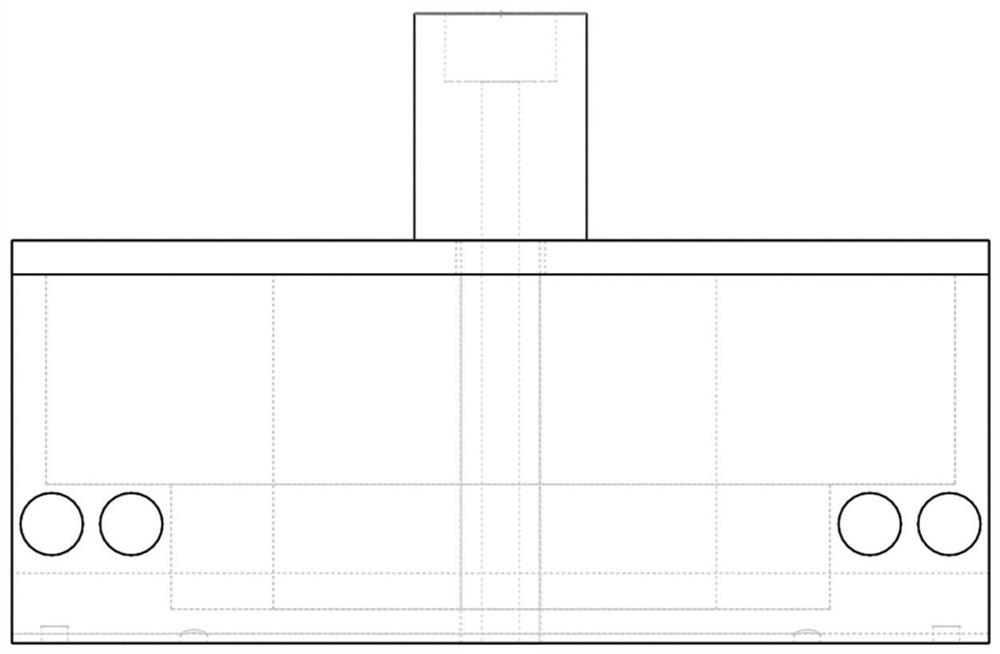

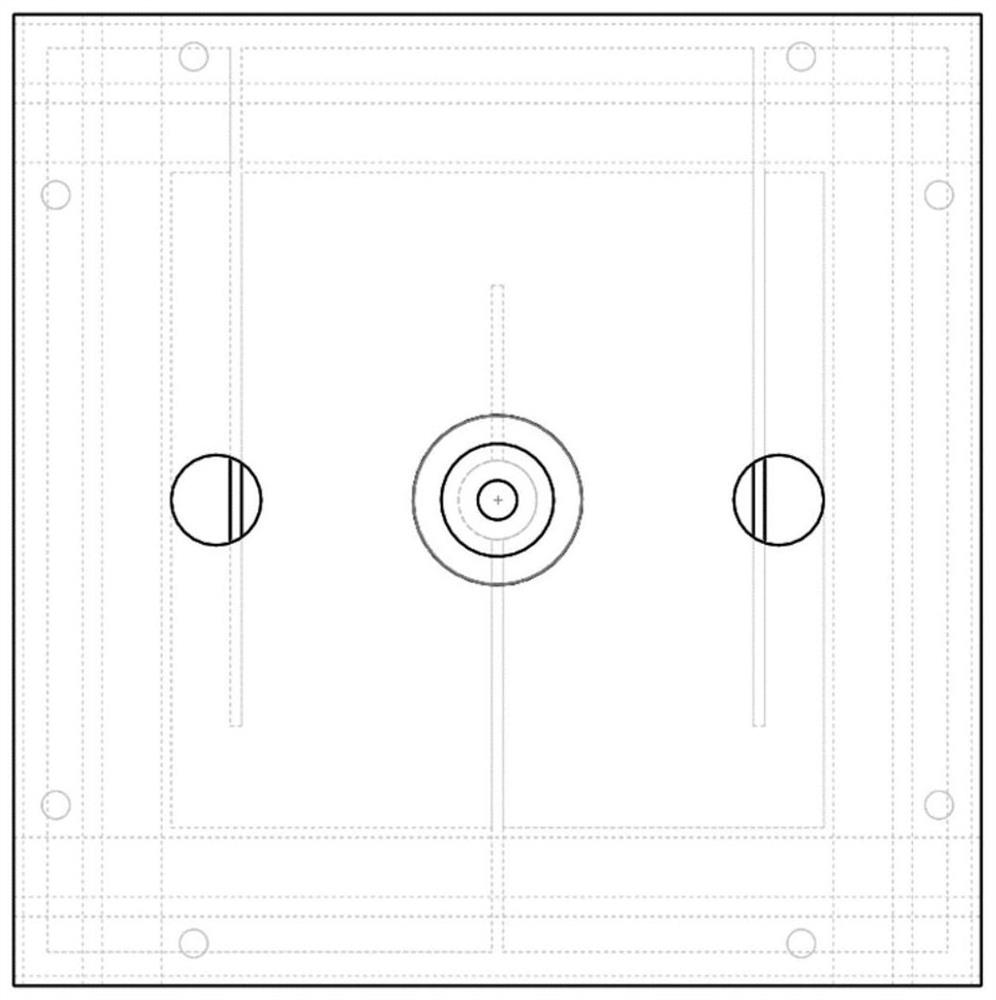

[0064] 1. A low-temperature substrate heating platform for growing semiconductor thin films, the structure comprising a heating part, a water cooling part, a thermocouple and a mask plate. The heating part is located around the lower part of the heating table, with infrared lamps inserted, which can directly heat the substrate through the stainless steel at the bottom of the heating table; the water cooling part is located in the water cooling chamber inside the heating table, and there are three waterway baffles inside the chamber for Realize the "S" shape of the internal water flow, which can increase the speed of water flow, expand the water cooling area at the bottom of the heating table, and improve the heat dissipation efficiency of the substrate; the thermocouple is located in the middle of the heating table, and the bottom of the thermocouple is flush with the bottom of the heating table , which can realize accurate temperature measurement of the substrate; the mask pla...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is that: n baffles are provided in the internal waterway, and n is greater than or equal to 1. If the size of the heating table is relatively large, it is necessary to add baffles to increase the flow rate of water inside the heating table; if the size of the heating table is relatively small, a relatively large water flow rate can be achieved by setting fewer baffles.

[0077] 1. A low-temperature substrate heating platform for growing semiconductor thin films, the structure comprising a heating part, a water cooling part, a thermocouple and a mask plate. The heating part is located around the lower part of the heating table, with infrared lamps inserted, which can directly heat the substrate through the stainless steel at the bottom of the heating table; the water cooling part is located in the water cooling chamber inside the heating table, and there are three waterway baffles inside the chamber for Realize the ...

Embodiment 3

[0089] 1. A low-temperature substrate heating platform for growing semiconductor thin films, the structure comprising a heating part, a water cooling part, a thermocouple and a mask plate. The heating part is located around the lower part of the heating table, with infrared lamps inserted, which can directly heat the substrate through the stainless steel at the bottom of the heating table; the water cooling part is located in the water cooling chamber inside the heating table, and there are three waterway baffles inside the chamber for Realize the "S" shape of the internal water flow, which can increase the speed of water flow, expand the water cooling area at the bottom of the heating table, and improve the heat dissipation efficiency of the substrate; the thermocouple is located in the middle of the heating table, and the bottom of the thermocouple is flush with the bottom of the heating table , which can realize accurate temperature measurement of the substrate; the mask pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com