Water-cooling spiral conveyor

A screw conveyor and water cooling technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low processing efficiency and inability to cool materials, and achieve the effect of recycling and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

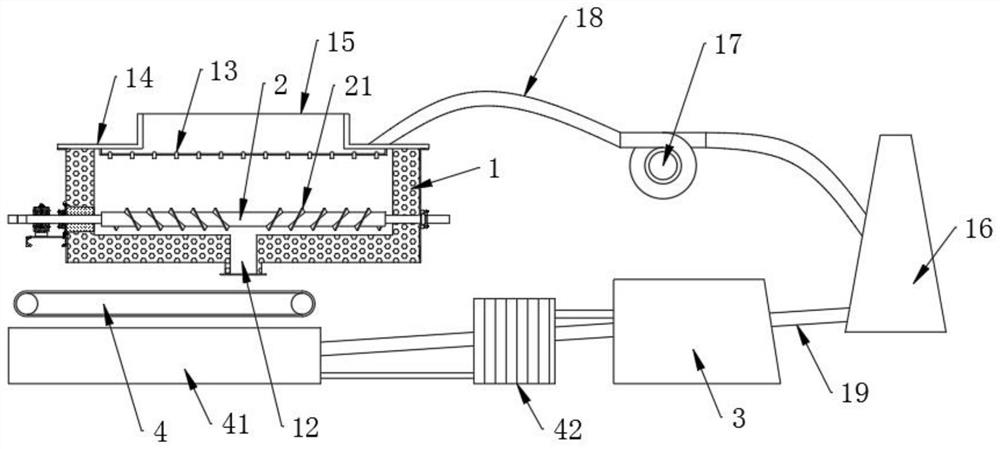

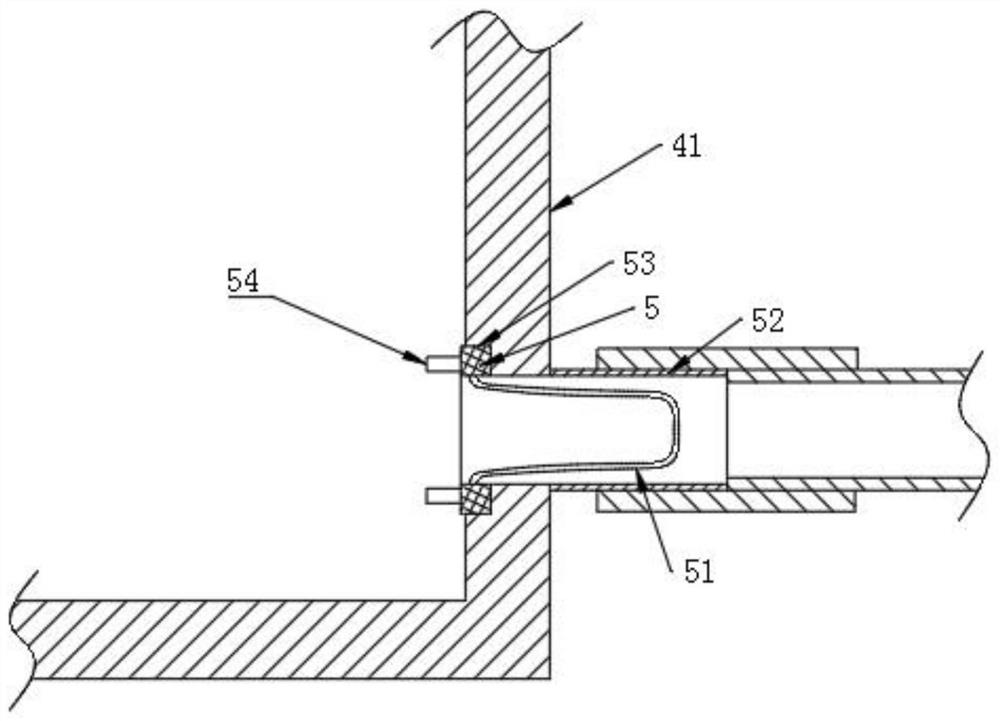

[0028] Embodiment: a kind of water-cooled screw conveyor, as figure 1 As shown, it includes a housing 1, the housing 1 is provided with a conveying shaft 2 along the length direction, the housing 1 is provided with a motor to drive the conveying shaft 2 to rotate, and the surface of the conveying shaft 2 is provided with a spiral blade 21 for crushing ash , the lower surface of the housing 1 is provided with a discharge port 12 for the ash to leave, the upper surface of the housing 1 is provided with a row of water spray heads 13 along its own length direction, and the housing 1 is provided with water supply for each water spray head 13 The water pump and the water storage tank 3, the water spray head 13 pointing to the conveying shaft 2, the mesh belt conveyor 4 for collecting ash and slag is arranged under the discharge port 12, and the mesh belt conveyor 4 is arranged for collecting water and fine slag. Frame 41 , the collection frame 41 and the water storage tank 3 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com