An air cooling device that uses cold airflow to cool down the temperature of brine

An air-cooling device and brine technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of small size and difficult heat exchange, so as to improve heat exchange efficiency, facilitate maintenance and inspection, and facilitate systematization and intelligence The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

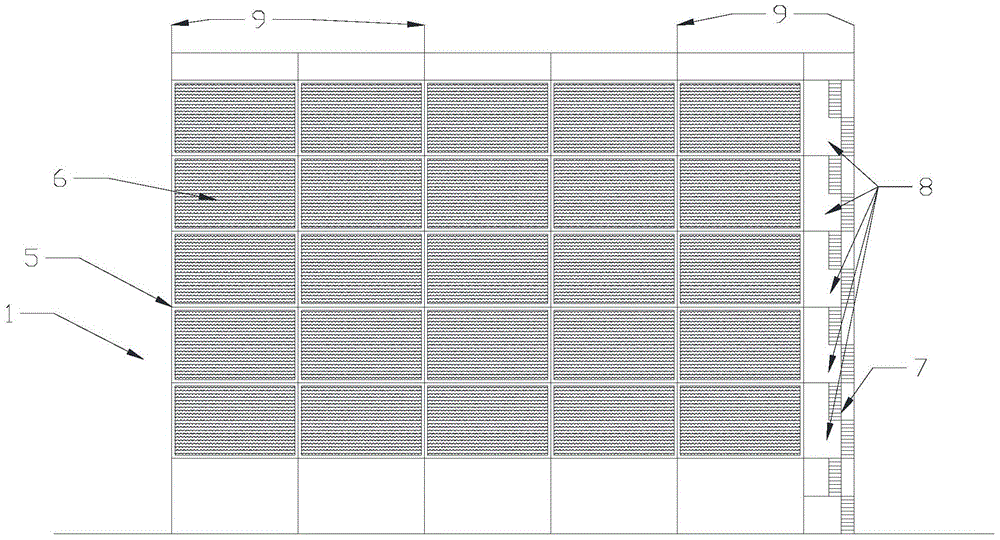

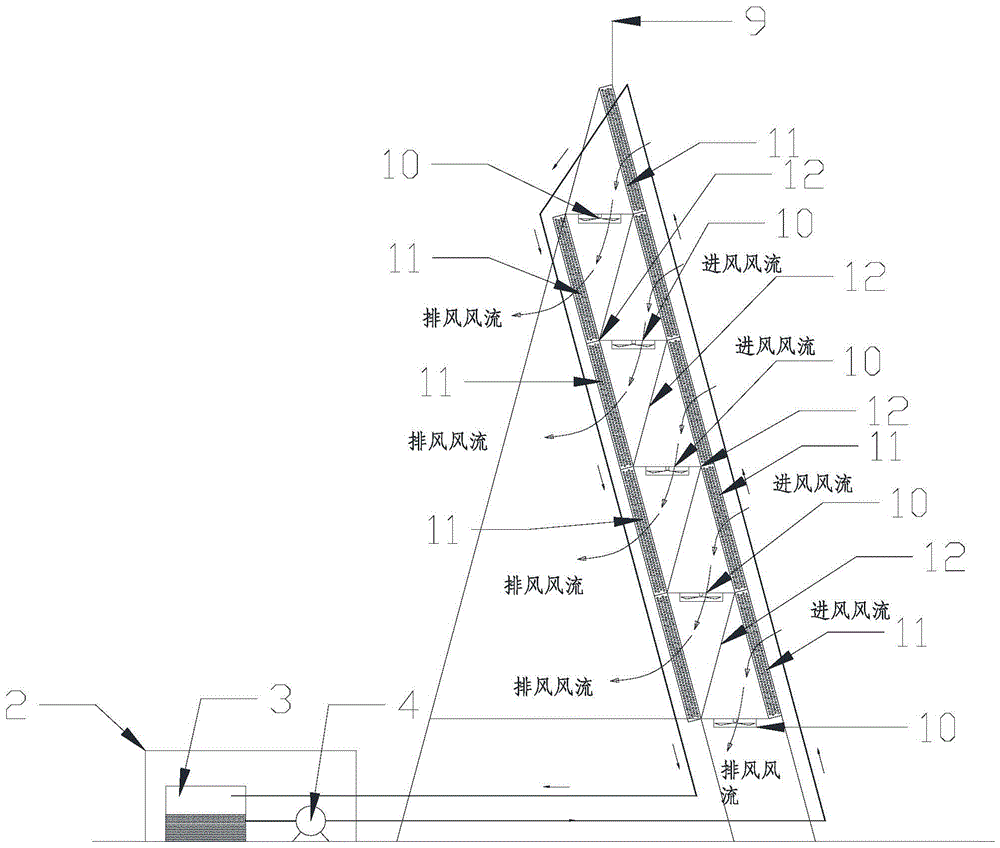

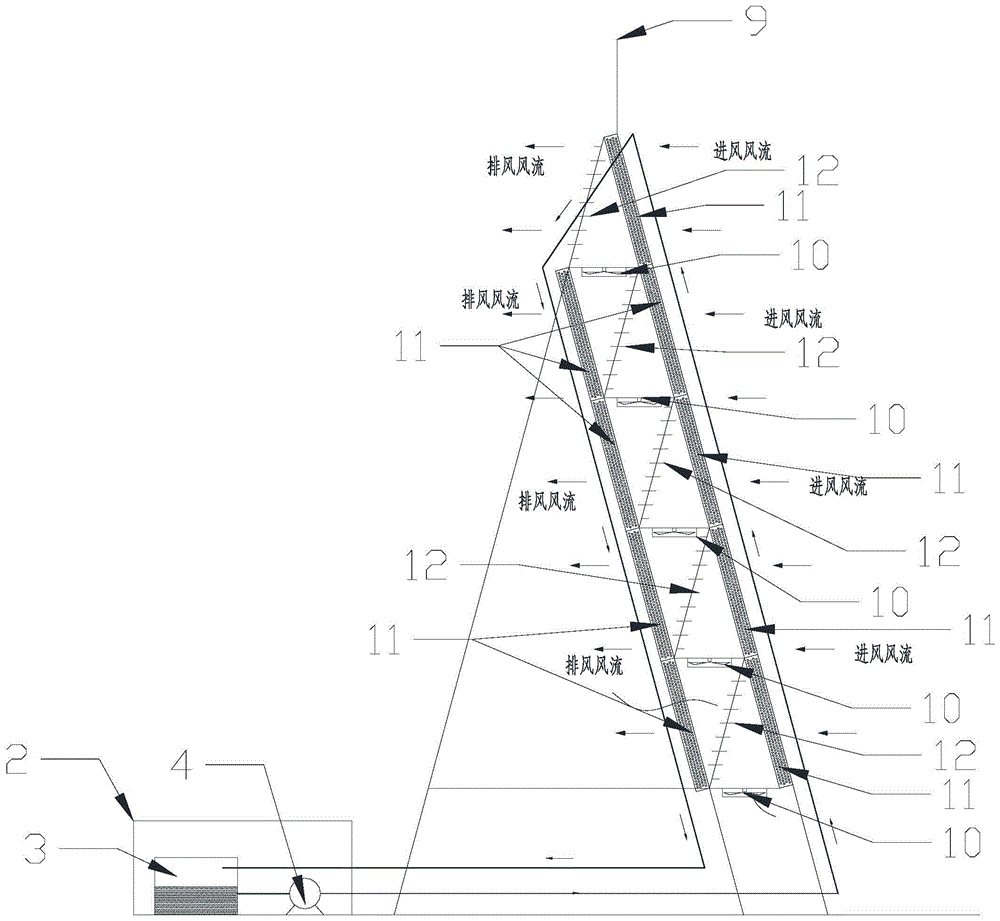

[0029] like Figure 1-6 As shown, the present invention utilizes cold air flow to carry out the air-cooling device for brine cooling, including an air-cooling wall structure 1, a brine pump 4 and a brine storage device 3, the air-cooling wall structure 1 includes a layer of air coolers greater than or equal to one layer, and the air-cooling The device includes greater than or equal to one air-cooling installation unit 6, and the air-cooling installation unit 6 includes a finned tube bundle frame, a finned tube bundle 11, a vertical louver 16, a horizontal louver 12 and a fan 10, the finned tube bundle 11, the vertical The louvers 16, the transverse louvers 12 and the fan 10 are respectively installed on the frame of the finned tube bundles, and the transverse louvers 12 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com