A variable-winding split-tooth permanent magnet synchronous vernier motor with multiple operating modes

A technology of permanent magnet synchronous and vernier motors, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, shape/style/structure of winding conductors, etc., can solve complex motor topology and drive control and other problems, to achieve the effect of high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

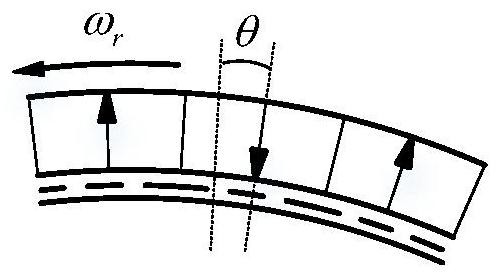

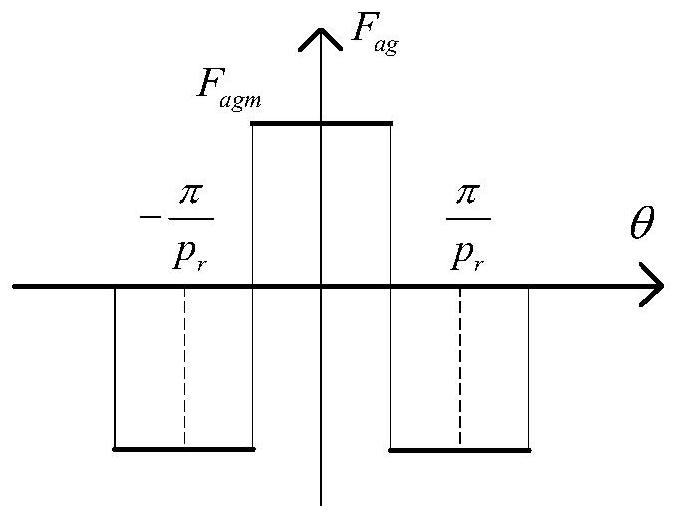

[0097] Such as Figure 5 As shown, a multi-operation mode permanent magnet synchronous vernier motor in this embodiment adopts an outer rotor structure, and the motor includes an inner stator 1, an outer rotor 2, a permanent magnet 3, an armature winding 4 and a rotating shaft 5, and the outer rotor 2 is arranged on On the rotating shaft 5, there is an air gap between the inner stator 1 and the outer rotor 2. The thickness of the air gap is related to the power level of the motor, the selected permanent magnet material and the processing and assembly process of the inner stator 1 and the outer rotor 2.

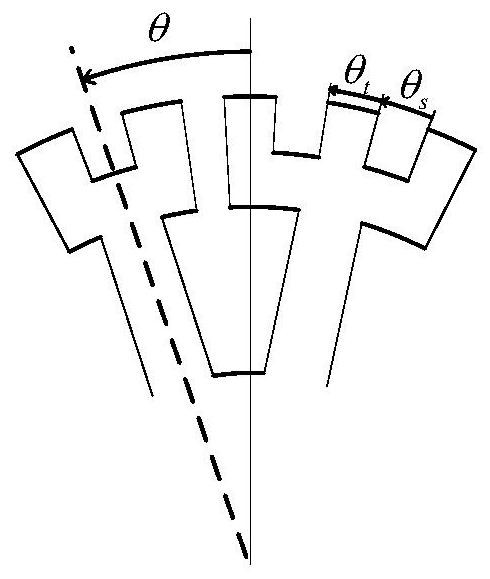

[0098] The inner stator 1 includes an inner stator core 1-1 and an armature winding 4. The inner stator core 1-1 includes an inner stator yoke 6 and 12 inner stator teeth 7, and 12 inner stators are formed between adjacent inner stator teeth 7. Slot 8, two or three split small teeth 9 are respectively arranged on two adjacent inner stator teeth 7, so there are altogether 30 spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com