Air-air heat exchanger and refrigerating device

A technology of air heat exchangers and refrigeration devices, which is applied in the direction of indirect heat exchangers, heat exchanger types, space heating and ventilation details, etc., and can solve the problems of single performance, inability to operate, and limited use of air conditioning systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

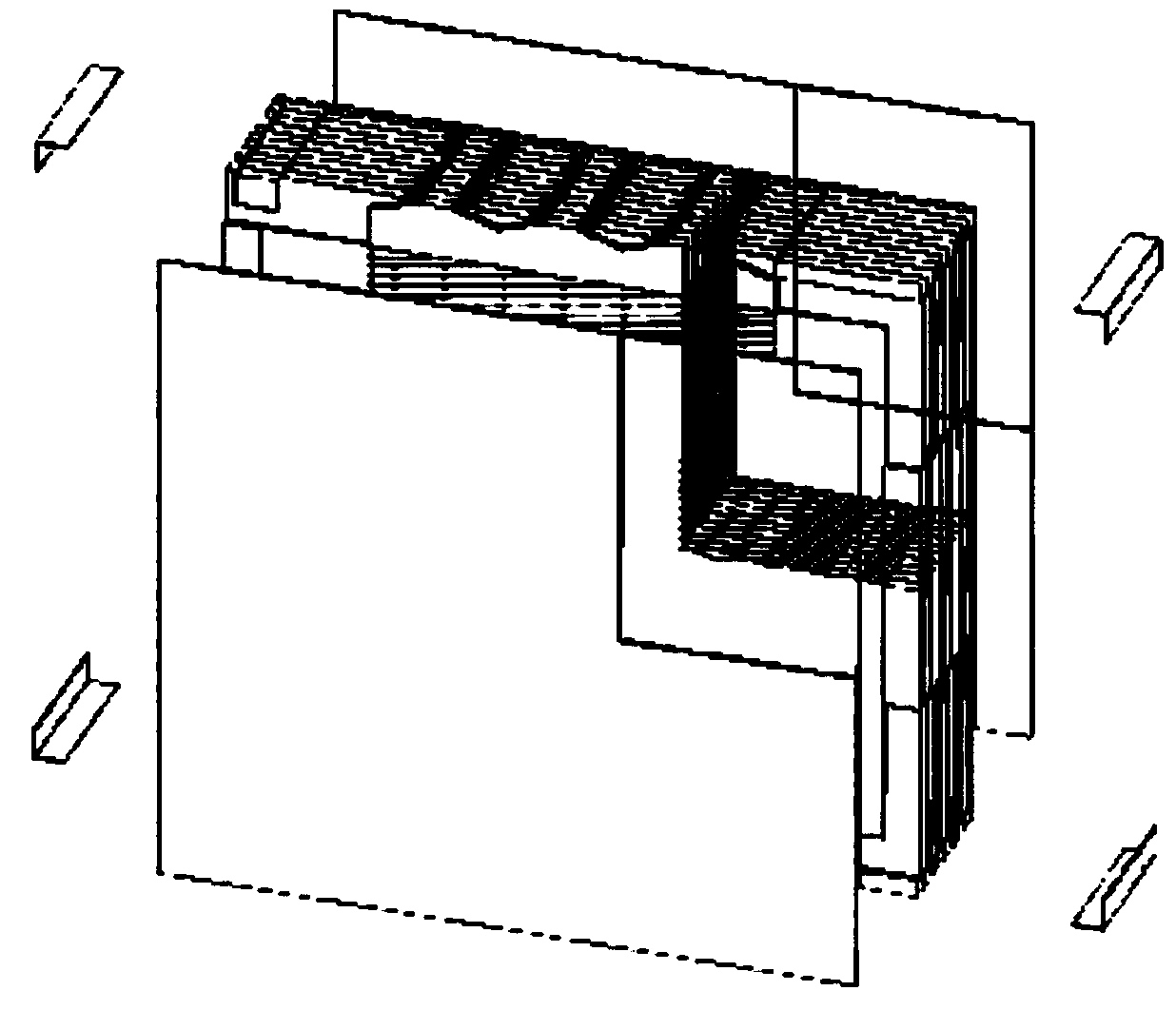

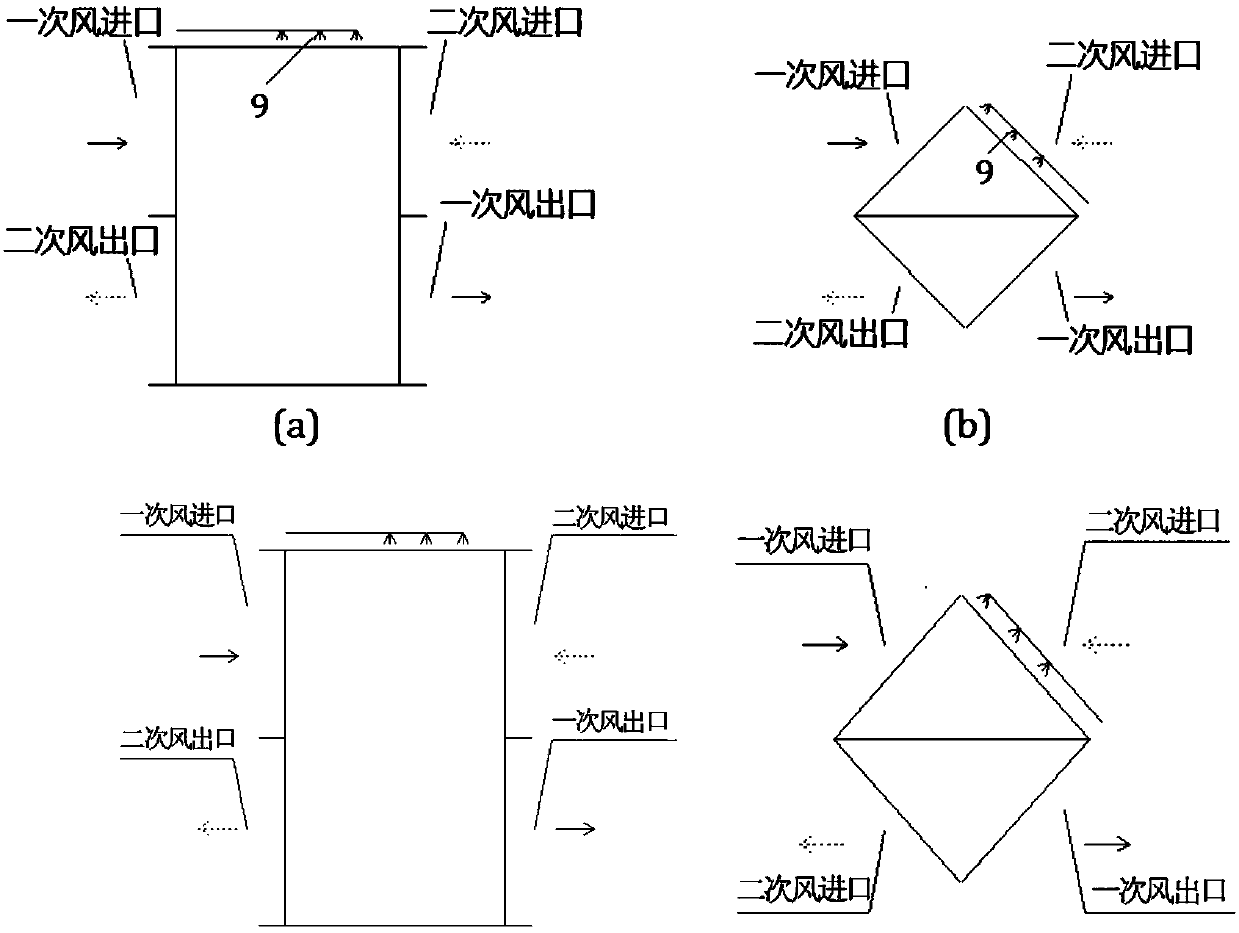

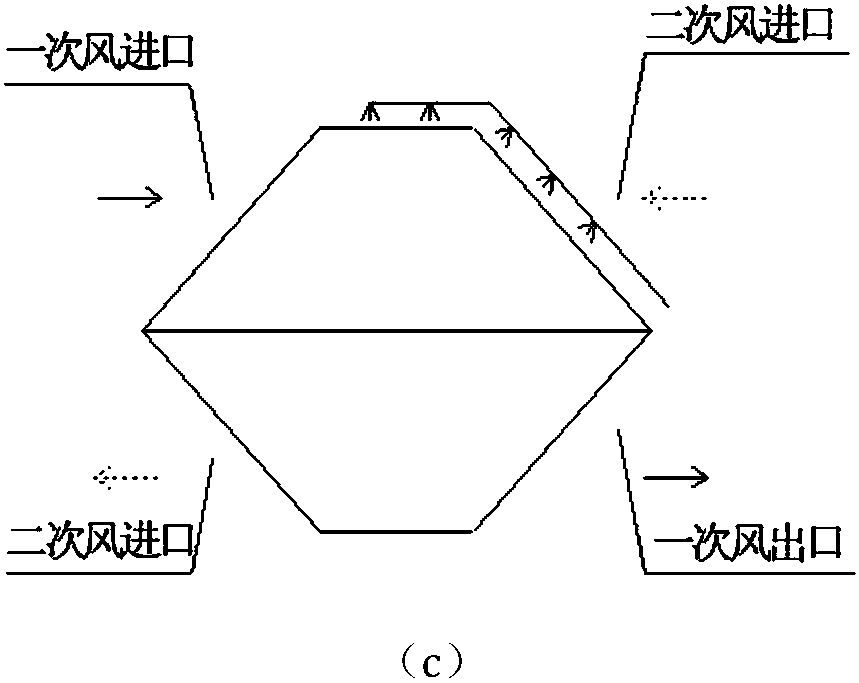

[0032] Such as figure 1 with figure 2 As shown, this embodiment relates to an air-to-air heat exchanger 8, comprising: stacked heat exchange membranes, wherein: a group of three adjacent heat exchange membranes is formed by a dry channel and a wet channel composed of heat exchange channels, the superimposed heat exchange channels constitute mutually independent primary air inlet (heat exchanger fresh air inlet 7), primary air outlet (heat exchanger fresh air outlet 20), secondary air inlet (heat exchanger return air inlet 10) and the secondary air outlet (heat exchanger return air outlet 1), the primary air inlet and the primary air outlet, the secondary air inlet and the secondary air outlet are in a diagonal relationship.

[0033] The primary air inlet, the primary air outlet, the secondary air inlet and the secondary air outlet can also be realized through heat exchange membranes and independent flow dividing and collecting mechanisms.

[0034] The heat exchange membrane...

Embodiment 2

[0057] Such as Figure 4 As shown, this embodiment further includes: a condenser 2, an evaporator 17 and a compressor 22, wherein: the condenser 2 is located between the return air fan 6 and the return air outlet 1 of the heat exchanger, and the evaporator 17 is located between the air supply fan 14 Between the fresh air outlet 20 of the heat exchanger and the air supply outlet 16 side; the compressor 22 is connected to the condenser 2 and the evaporator 17 respectively.

[0058] The compressor 22 is connected to the condenser 2 and the evaporator 17 through a four-way reversing valve 23, wherein: the main valve of the four-way reversing valve 23 is connected to the exhaust port of the compressor 22, and the three control valves are respectively connected to The air inlet of the condenser 2, the air outlet of the evaporator 17 and the air inlet of the compressor 22 are connected.

[0059] The air outlet of the condenser 2 is connected with the air inlet of the evaporator 17, ...

Embodiment 3

[0079] Such as Figure 5 As shown, this embodiment further includes: a condenser 2, an evaporator 17 and a compressor 22, wherein: the air supply fan 14 is located between the fresh air filter 5 and the fresh air inlet 7 of the heat exchanger, and the return air fan 6 is located at the return air outlet 15 and the return air inlet 10 of the heat exchanger; the condenser 2 is located between the outlet 3 and the return air outlet 1 of the heat exchanger, and the evaporator 17 is located at the end of the fresh air duct 25 near the air supply outlet 16; The condenser 2 is connected to the evaporator 17 .

[0080] This embodiment includes eight modes, namely: 100% fresh air dew point evaporative cooling mode, 100% fresh air dew point evaporative cooling + mechanical cooling mode, fresh air ratio adjustable mode, fresh air ratio adjustable + mechanical cooling mode, 100% indirect evaporative cooling mode, 100% indirect evaporative cooling + mechanical cooling mode, 100% heat reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com