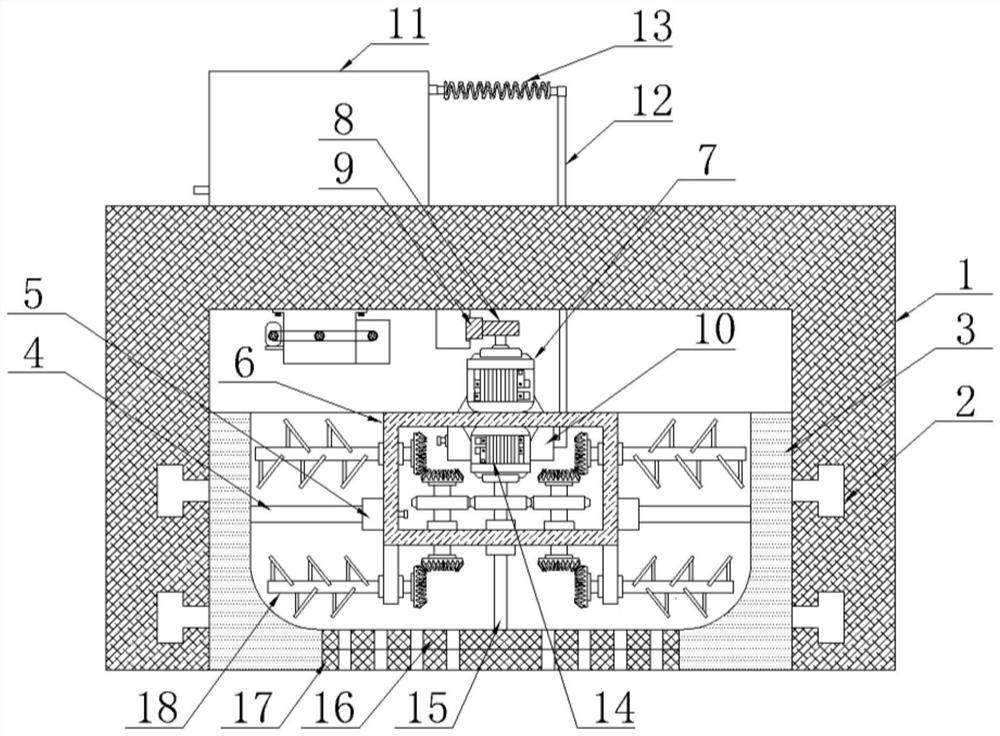

Granular fertilizer spreading equipment of seedling raising device for radix paeoniae alba planting

A seedling raising device and granular technology, which is applied in the field of granular fertilizer spreading equipment, can solve problems such as uneven spreading and affecting the uniformity of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

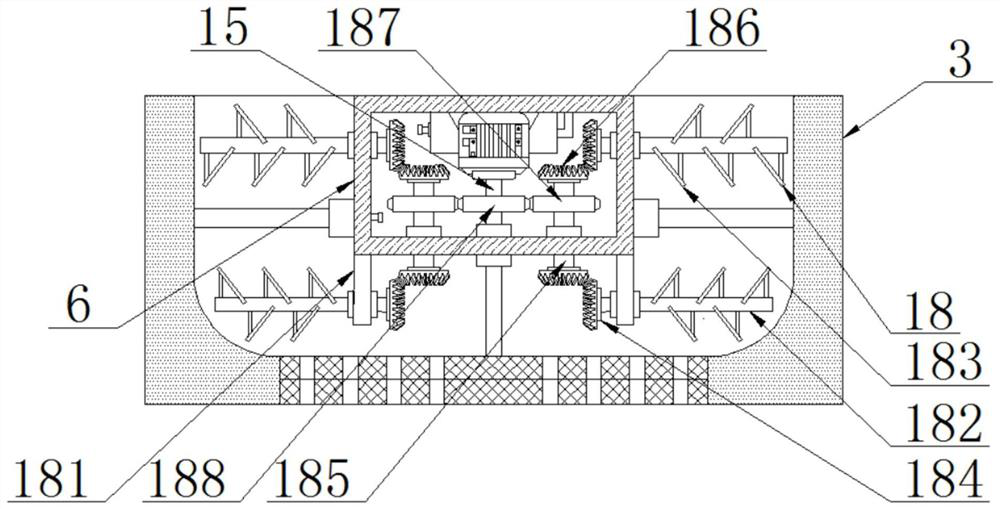

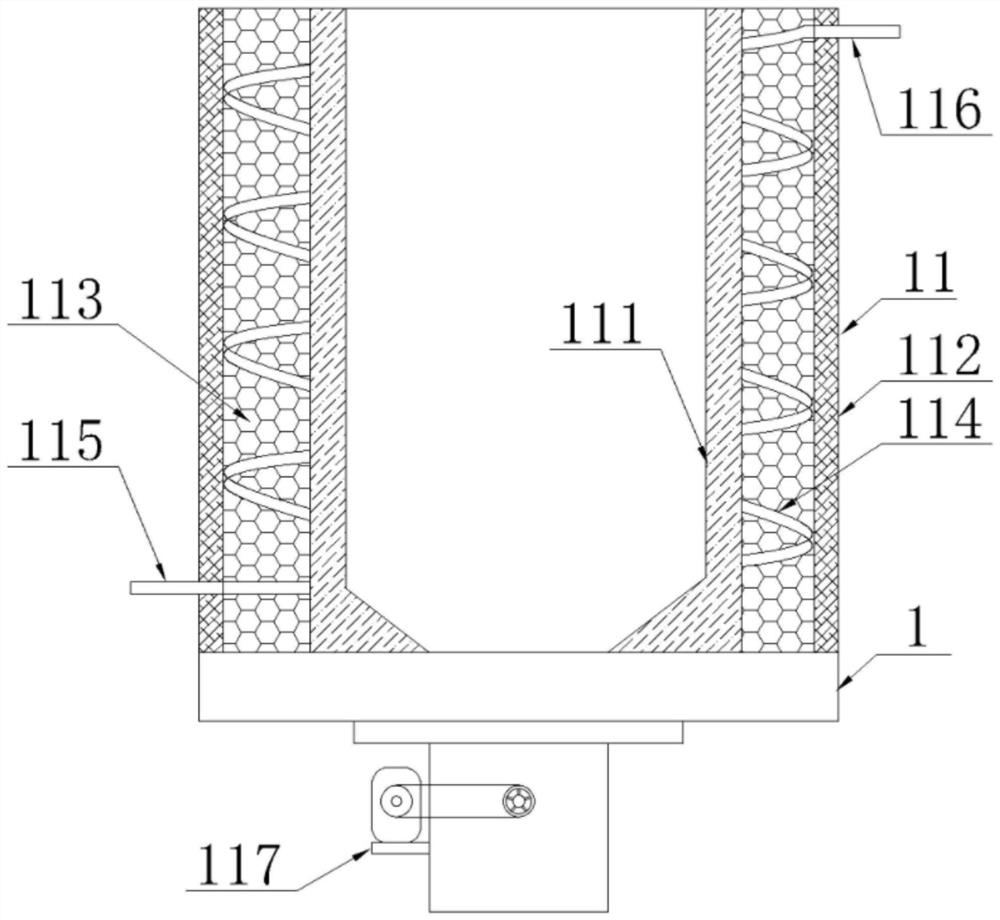

[0027] 1) Fertilizer dispensing: Fertilizer is put into the fertilizer tank 11, the drive motor 11702 is started, and the drive motor 11702 drives the rotating shaft 11706 and the drum 11707 to rotate counterclockwise. The fertilizer can only enter the bottom of the shell 11701 through the groove 11708 and be screened by the screen 11712 After falling into the connecting shell 3, the fertilizer with larger particles enters the coarse particle discharge assembly 11703 through the feeding channel 11713, and the processed fertilizer particles are relatively fine, and there is no fertilizer accumulation during fertilization, resulting in uneven fertilization , the lower motor 14 drives the rotating rod 15 and the upper orifice plate 16 to rotate. At this time, the fertilizer of small particles is discharged through the discharge holes on the upper orifice plate 16 and the lower orifice plate 17, and the upper motor 7 drives the main gear 8 to rotate, so that The connecting shell 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com