Automatic paint mixing system

A paint mixing and vibrator technology, applied in the field of paint mixing, can solve the problems of clogging the paint mixing device, mixing impurities or foreign objects, affecting the quality of the paint, etc., and achieving the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments.

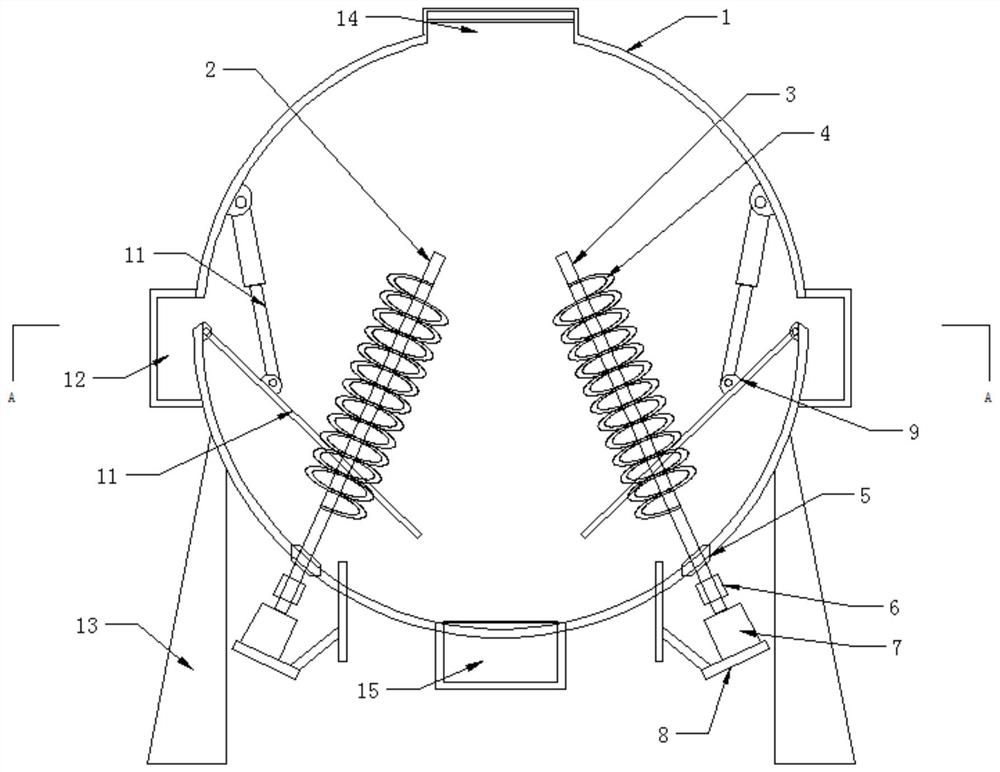

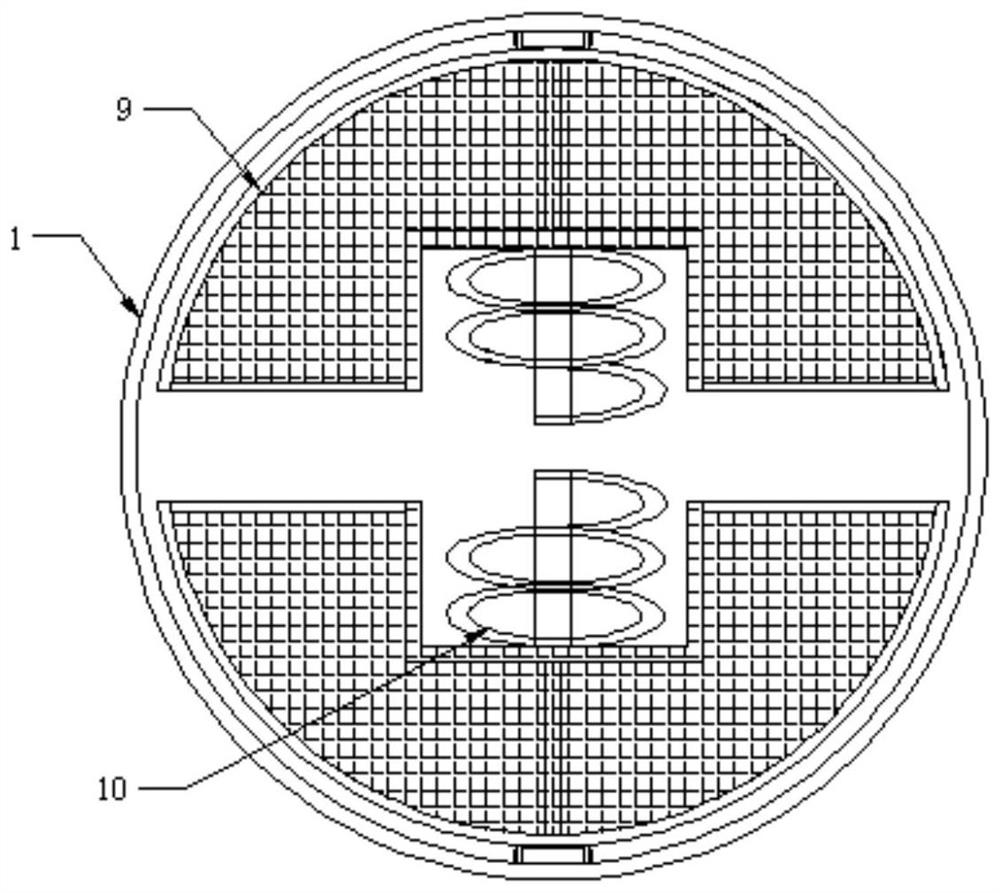

[0019] figure 1 It is a schematic structural diagram of an automatic paint mixing system of the present invention; it includes a spherical kettle 1, and is characterized in that: two mutually symmetrical spoilers 2 are arranged at the bottom of the spherical kettle 1, and the spoilers 2 include a penetrating ball. The kettle 1 is also tilted upward to the rotating shaft 3, the rotating shaft 3 is connected to the spherical kettle 1 in rotation through the sealing shaft sleeve 5, and the rotating shaft 3 in the spherical kettle 1 is provided with a spiral annular stirring blade 4, and the spiral annular stirring blade 4. Both ends are respectively fixed on the rotating shaft 3, the middle non-contact sleeve is sleeved on the rotating shaft 3, and a vibrator 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com