Double-strand slab continuous casting operation method

A slab continuous casting and double-strand slab technology, which is applied in the field of metallurgy, can solve problems affecting production, achieve the effects of improving operation rate, reducing downtime and maintenance time, and preventing pulling failure accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention is now described.

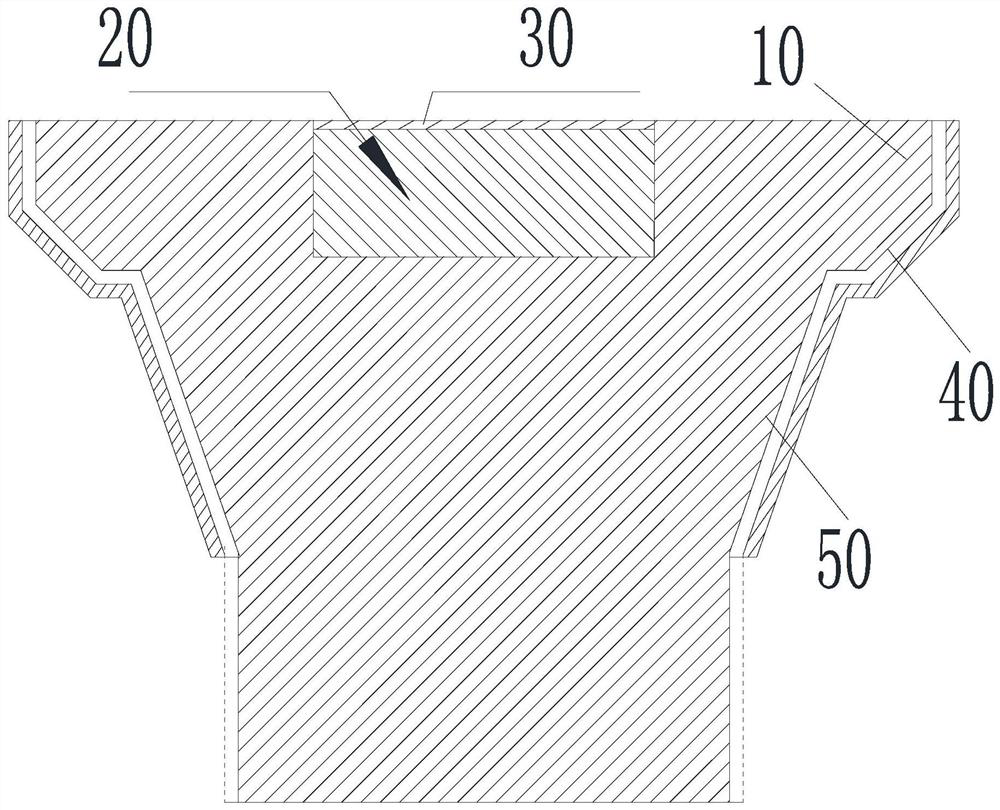

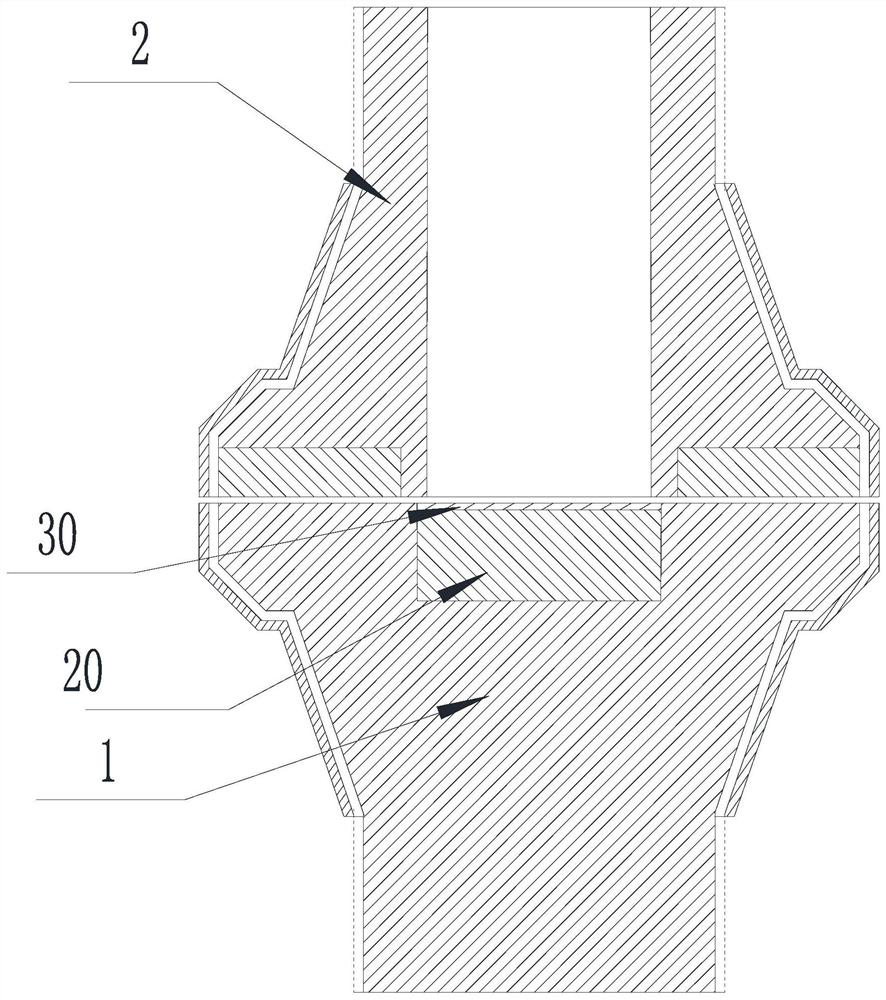

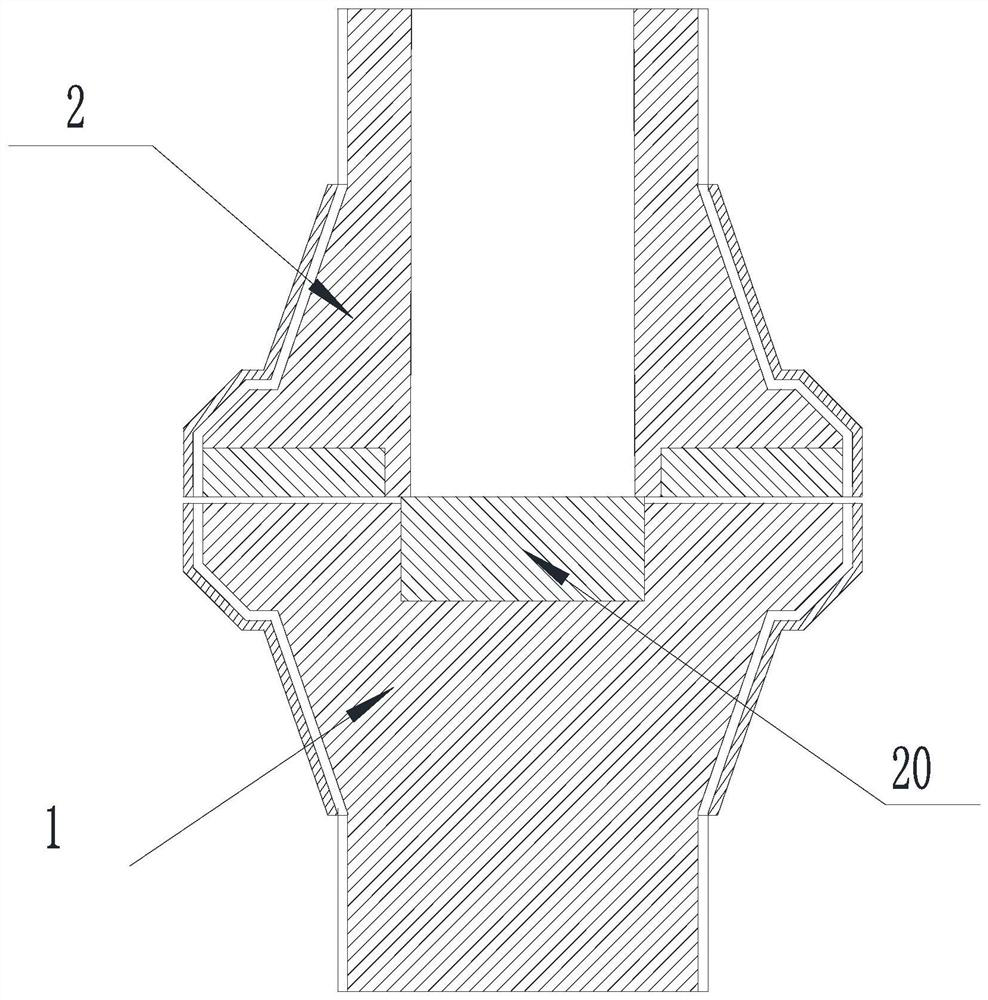

[0041] Taking a converter with a tapping capacity of 150t and a double-strand slab caster with cross-sections of 220mm×1250mm and 220mm×800mm to produce SPHC series steel grades as an example, the working method of the present invention includes the following steps:

[0042] T1: Method for safely stopping flow of double-strand slab continuous casting machine during pouring;

[0043] T2: The method of closing and capping the slab continuous casting;

[0044] T3: Method for non-stop local overhaul of double-strand slab caster after closing and capping;

[0045] T4: The method of changing the cross section during pouring of the double-strand slab continuous caster after maintenance;

[0046] T5: the method of re-opening after the flow of the double-strand slab continuous casting machine after changing the cross-secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com