A kind of ready-mixed mortar mixing device, production process and impermeability and anti-cracking ready-mixed mortar

A technology of ready-mixed mortar and mixing device, which is applied in the field of ready-mixed mortar, can solve the problems of lack of simple, efficient and suitable for mass production methods, etc., and achieve the improvement of pre-mixing efficiency and quality, simple structure, and improved mixing Effects and Effects of Mixing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

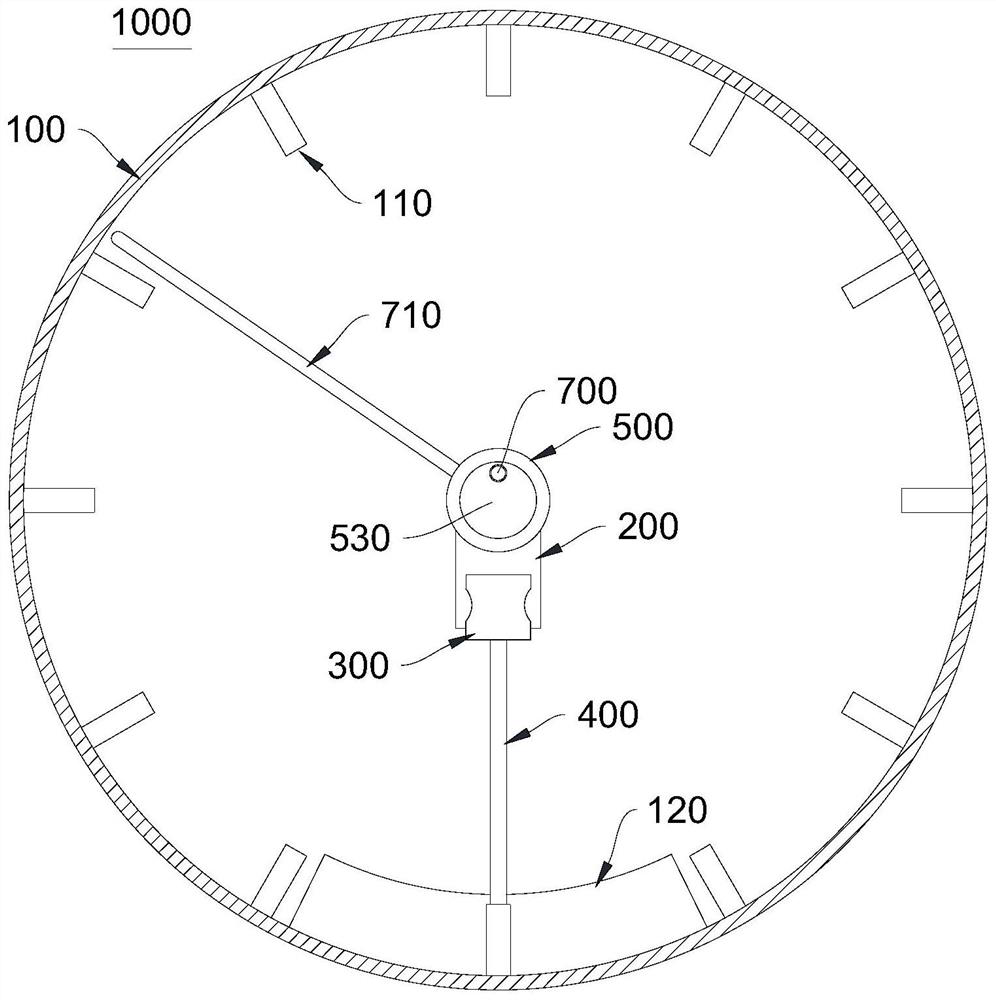

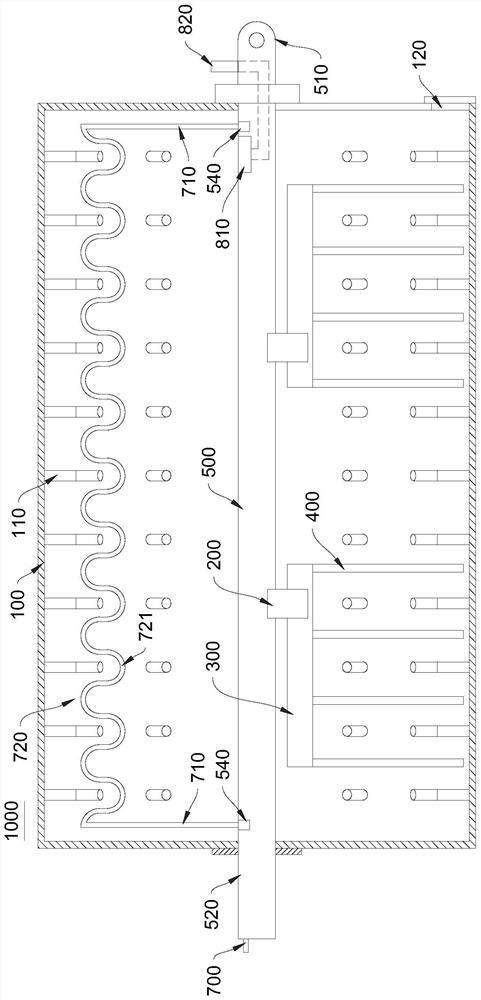

[0045] Please refer to Figure 1~2, this embodiment provides a new mixing device 1000 for ready-mixed mortar.

[0046] The new mixing device 1000 for ready-mixed mortar includes: a tank body 100 and a main shaft 500 .

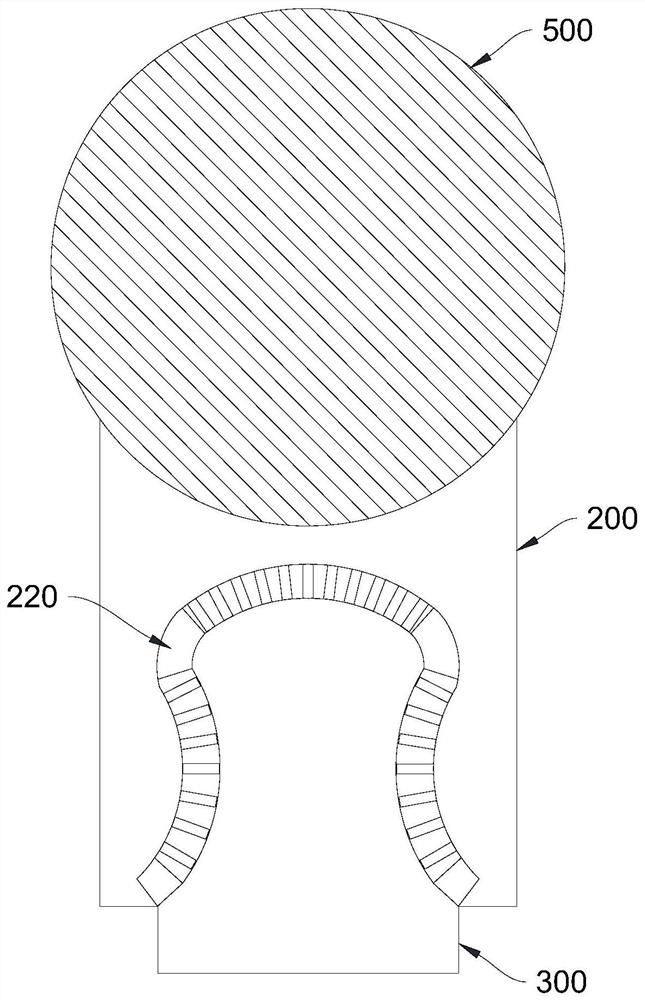

[0047] Main shaft 500 adopts horizontal setting, and main shaft 500 is coaxially arranged with tank body 100, and main shaft 500 runs through the two ends of tank body 100, and the outer wall of tank body 100 and main shaft 500 is rotationally sealed. The tank body 100 can rotate relative to the main shaft 500 .

[0048] One end of the main shaft 500 is provided with a first matching portion 510 for hinged connection with the pile foundation 600 , and the other end is provided with a second matching portion 520 for matching with a lifting assembly (not shown in the figure). Driven by the lifting assembly, the main shaft 500 can be slightly tilted in the horizontal direction by lifting or lowering the end where the second matching part 520 of the main shaft 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com