Underwater cavitation cleaning disc, device and system

A disk cleaning and cavitation technology, which is applied to ship cleaning devices, transportation and packaging, cleaning methods and appliances, etc., can solve the problems of affecting the speed of the hull, corrosion of metal structures, and increased cost consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

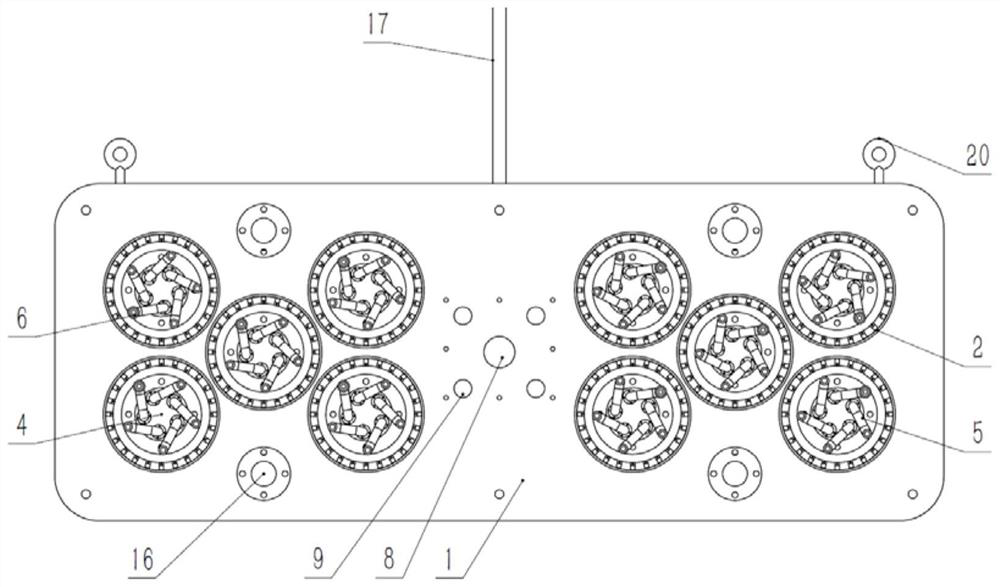

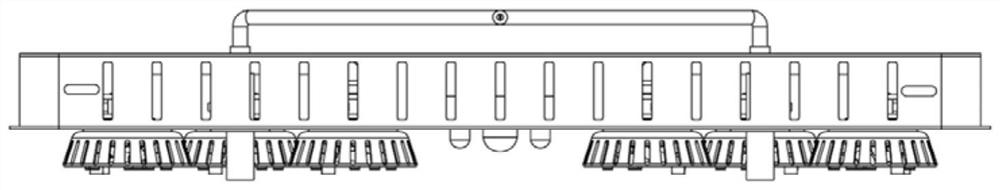

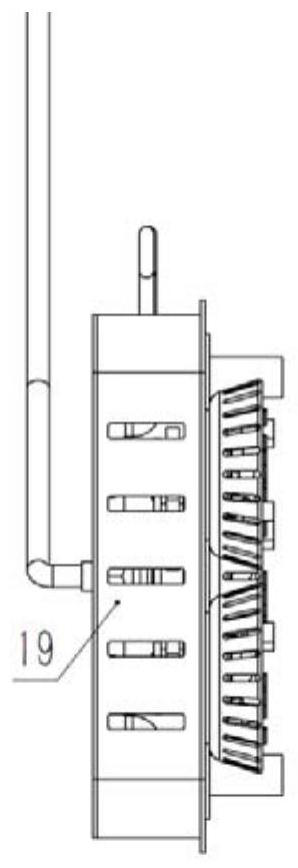

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The invention relates to an underwater cavitation cleaning device, comprising a high-pressure water pump, a water inlet pipe, a plurality of high-pressure rubber hoses, a pressure sensor, a cavitation control solenoid valve, a flange connection seat, a nozzle connection seat, and multiple groups of cavitation nozzles. Pipe, cavitation nozzle, front and rear mounting plates, also equipped with recoil hose, recoil control solenoid valve, recoil nozzle pressure sensor and recoil nozzle. The present invention adopts multiple groups of cavitation nozzles to operate at the same time, so that the area of the cleaning area is larger, and the number of positions of the cavitation nozzles and nozzles can be adjusted at any time. Each cavitation disk is controlled by a cavitation control solenoid valve and a pressure sensor, which can The cavitation intensity of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com