Safety plier automatic triggering mechanism for telescopic elevator mounting platform

An installation platform and automatic triggering technology, which is applied in elevators, transportation and packaging, building construction, etc., can solve the problems of relying on manual work, safety gear triggering mode or complex structure, and inconvenient use, so as to achieve low use and maintenance costs, The effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

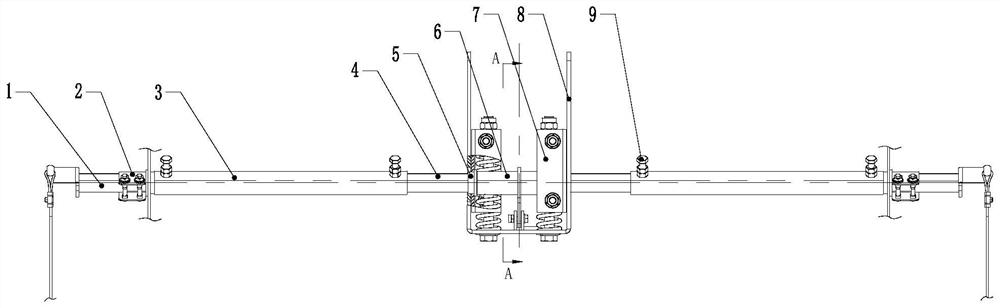

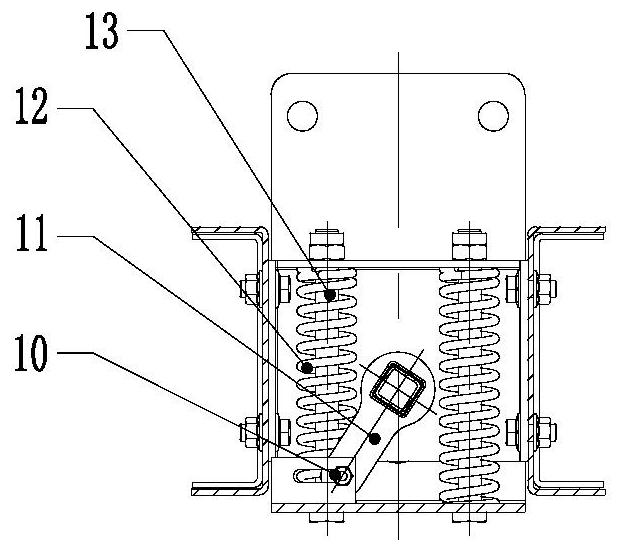

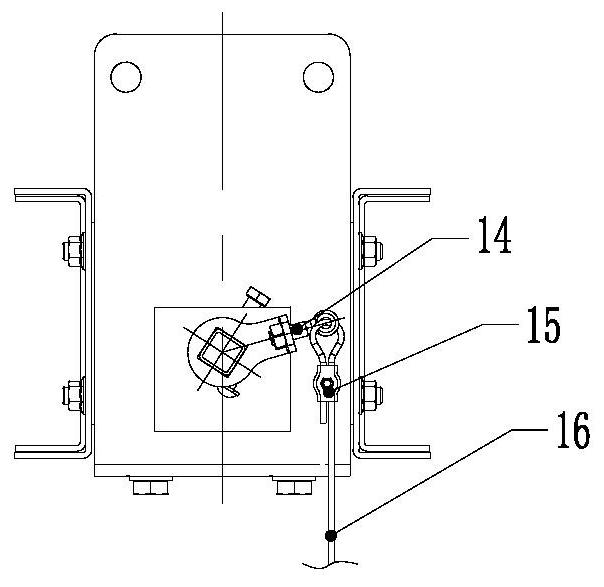

[0029] like Figure 1 to Figure 4 As shown: the present invention mainly includes a trigger lever 1, a square tube lock 2, a thick horizontal tube 3, a thin horizontal tube 4, a square tube sleeve 5, a positioning tube 6, an inverted U-shaped plate 7, a U-shaped plate 8, and fastening screws 9. Connecting screw 10, trigger movable part 11, compression spring 12, spring rod 13, joint bolt 14, rope clamp 15, steel wire rope 16, angle steel 17, extension spring 18, safety gear 19, pull plate 20, side connecting plate 21 , Side C steel 22, middle C steel 23, etc. The inverted U-shaped plate 7 is fixed between the two middle C-steels 23; the U-shaped plate 8 is a U-shaped structure, which is set on the outside of the two inverted U-shaped plates 7; the spring rod 13 is worn on the inverted U-shaped plate 7 Between the U-shaped plate 8, four compression springs 12 are sleeved on four spring rods 13 respectively.

[0030] The side walls on both sides of the U-shaped plate 8 have ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com