Edging etching solution for camera glass and use method of edging etching solution

A camera and etching solution technology, applied in the field of etching solution, can solve the problems of difficult processing of camera glass, easy to break, broken glass cover, etc., and achieves good application prospects and the effect of soft micro-pit curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

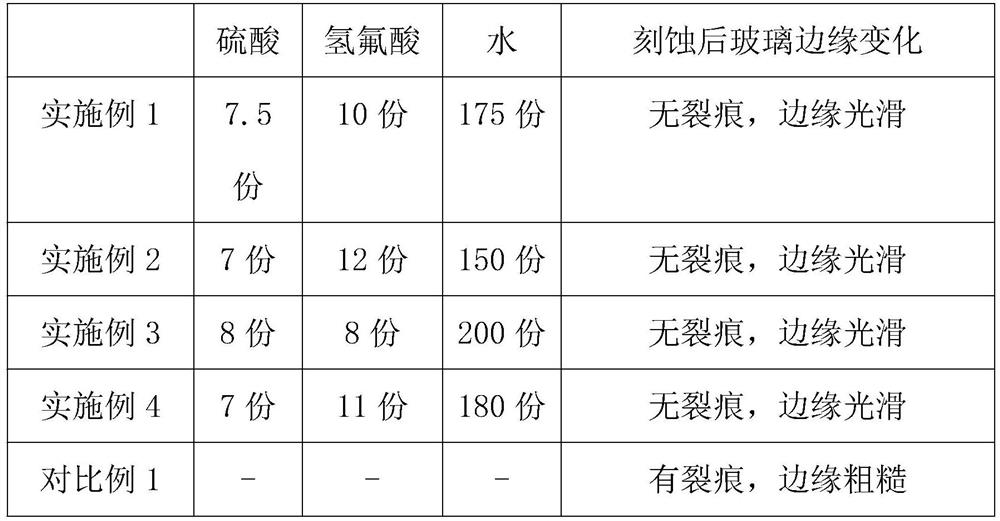

Embodiment 1

[0019] An edging etchant for camera glass is measured in parts by weight, and its preparation raw materials include:

[0020] 10 parts of hydrofluoric acid solution, the weight fraction of hydrofluoric acid molecules contained in the hydrofluoric acid solution is 30wt%, the contained chloride content is 0.001wt%, and the contained sulfate content is 0.002wt%.

[0021] 7.5 parts of sulfuric acid solution, the weight fraction of sulfuric acid molecules is 80wt%.

[0022] 175 parts of water.

[0023] According to above-mentioned formula, a kind of method of processing the use method of grinding etchant for camera glass of the present invention comprises the following steps:

[0024] Step 1: Add 10 parts of hydrofluoric acid solution, 7.5 parts of sulfuric acid solution and 175 parts of water into the batching tank and mix evenly to obtain a mixed solution. After stirring evenly, dilute to obtain an edging etchant for camera glass. The stirring temperature of the mixed solution ...

Embodiment 2

[0028] An edging etchant for camera glass is measured in parts by weight, and its preparation raw materials include:

[0029] 12 parts of hydrofluoric acid solution, the weight fraction of the hydrofluoric acid molecule contained in the hydrofluoric acid solution is 40wt%.

[0030] 7 parts of sulfuric acid solution, the weight fraction of sulfuric acid molecules is 90wt%.

[0031] 150 parts of water.

[0032] According to above-mentioned formula, a kind of method of processing the use method of grinding etchant for camera glass of the present invention comprises the following steps:

[0033] Step 1: Add 12 parts of hydrofluoric acid solution, 7 parts of sulfuric acid solution and 150 parts of water into the batching tank and mix evenly to obtain a mixed solution. After stirring evenly, dilute to obtain an edging etchant for camera glass. The stirring temperature of the mixed solution The temperature is 60° C., the stirring time is 10 min, and the concentration of the etchant...

Embodiment 3

[0037] An edging etchant for camera glass is measured in parts by weight, and its preparation raw materials include:

[0038] 8 parts of hydrofluoric acid solution, the weight fraction of hydrofluoric acid molecules contained in the hydrofluoric acid solution is 10wt%, the contained chloride content is 0.001wt%, and the contained sulfate content is 0.002wt%.

[0039] 8 parts of sulfuric acid solution, the weight fraction of sulfuric acid molecules is 98.3wt%.

[0040] 200 parts of water.

[0041] According to above-mentioned formula, a kind of method of processing the use method of grinding etchant for camera glass of the present invention comprises the following steps:

[0042] Step 1: Add 8 parts of hydrofluoric acid solution, 8 parts of sulfuric acid solution and 200 parts of water into the batching tank and mix evenly to obtain a mixed solution. After stirring evenly, dilute to obtain an edging etchant for camera glass. The stirring temperature of the mixed solution The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com