Cotton slitter with static electricity and impurity removing functions

A technology of static electricity removal and cotton opener, which is applied in the agricultural field, can solve the problems that the quality of cotton blocks or cotton bundles cannot meet the requirements, the cotton cannot be completely loosened, and the quality of finished products is reduced, so as to achieve convenient control, simplified structure, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

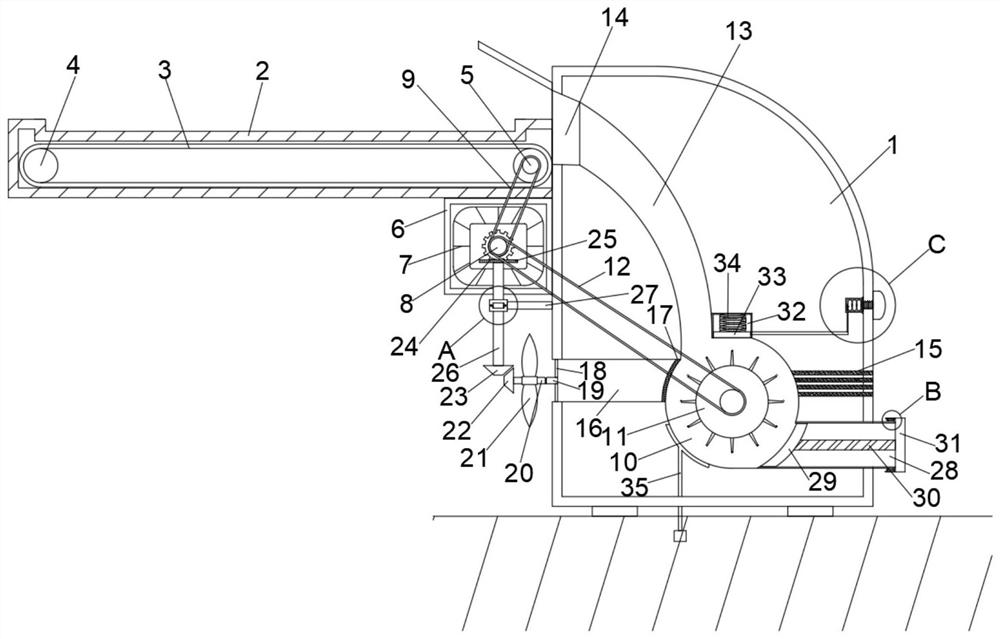

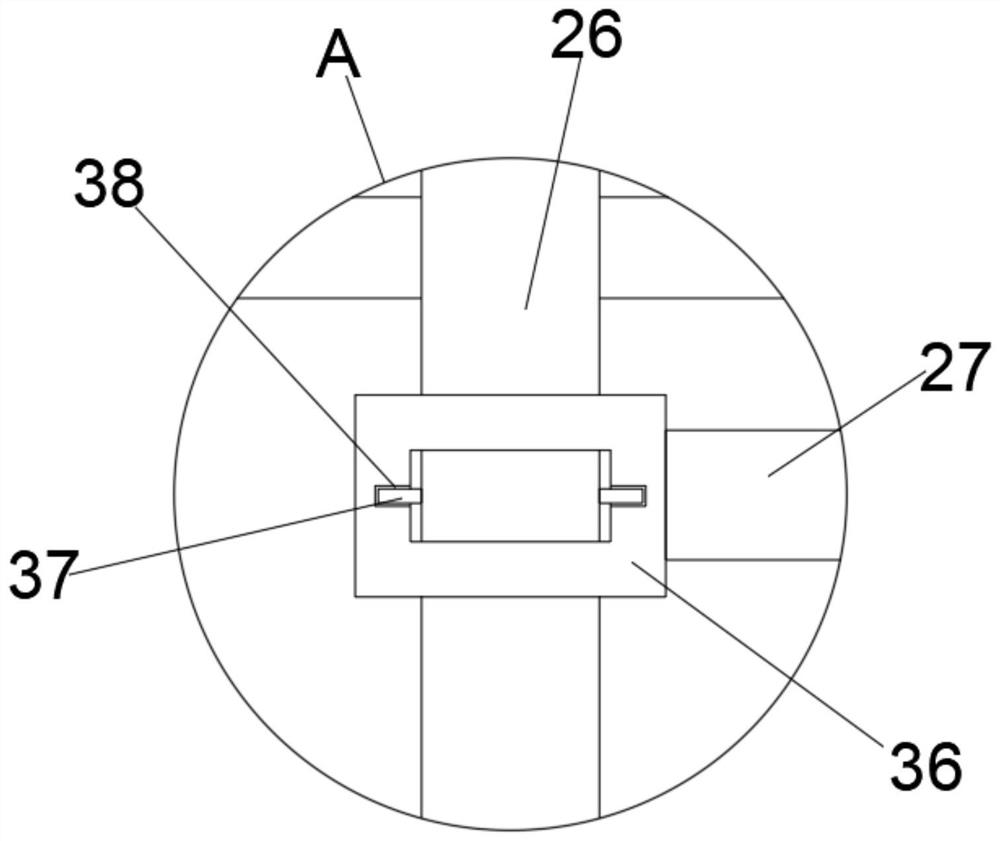

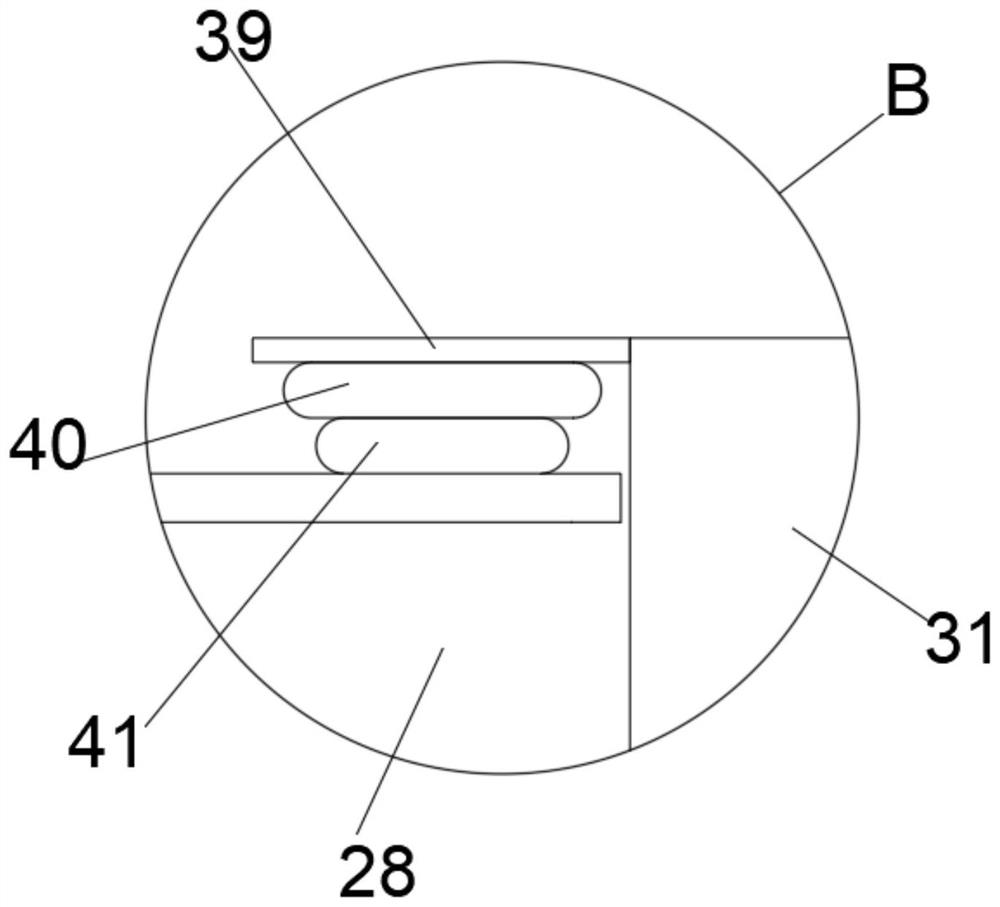

[0023] refer to Figure 1-4, a cotton opener with the functions of removing static electricity and impurities, comprising a body 1 and a feed trough 2 fixed on the upper side wall of the body 1, a guide plate is fixed on the outer side wall of the body 1, and the guide plate The top of the chute 2 is set to prevent the cotton from being transmitted on the conveyor belt and when it enters the body 1, the cotton will be scattered. The feed chute 2 is provided with a conveyor belt 3, and the two ends of the conveyor belt 3 are rotated There is a runner 4, and the conveyor belt 3 is wound on the runner 4, and the runner 4 arranged close to the body 1 is concentrically fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com