Sliding locking type non-woven fabric surface scraping device

A technology of non-woven fabrics and sliding locks, which is applied in the direction of processing textile materials equipment configuration, etc., and can solve the problems of non-woven fabric surface damage, inconvenient use, and reduced scraping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

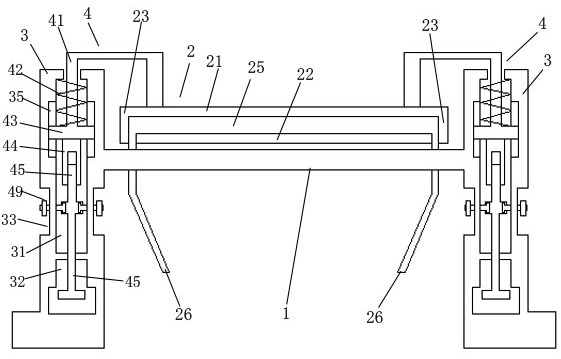

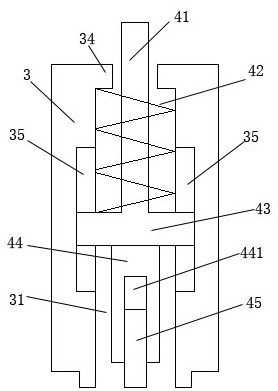

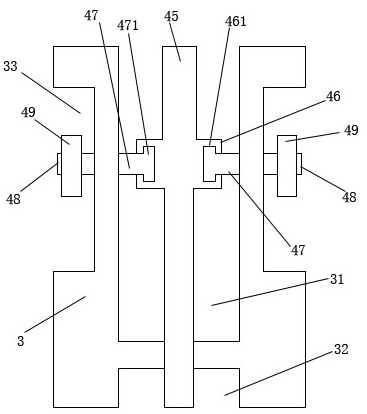

[0022] Such as Figures 1 to 5 As shown, a sliding locking non-woven fabric surface scraping device includes a lower bottom plate 1 , an upper scraping mechanism 2 , a support column 3 , and an abutting and separating mechanism 4 . A support column 3 is respectively installed on both sides of the lower base plate 1; the upper scraping mechanism 2 is installed above the lower base plate 1; an abutment separation mechanism 4 is respectively installed on the support column 3; The inside is provided with a butt separation cavity 31; the bottom of the support column 3 is provided with a drive hollow groove 32 that penetrates front and back; the abutment separation cavity 31 and the drive hollow groove 32 are connected up and down respectively; the support column 3 An annular positioning groove 33 is provided on the outside around the middle; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com