Fabricated concrete member box-shaped sleeve type connecting structure, construction method and application

A technology for connecting structures and concrete, applied in building components, building structures, walls, etc., can solve the problems of safety threats, high construction requirements, and slurry fallback of prefabricated concrete frame structures, so as to meet the requirements of structural integrity, Convenience in construction and avoidance of steel bar collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

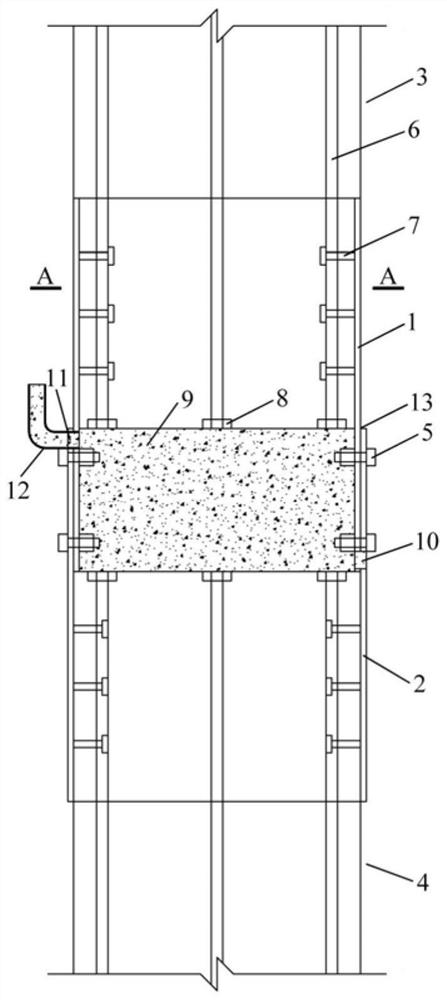

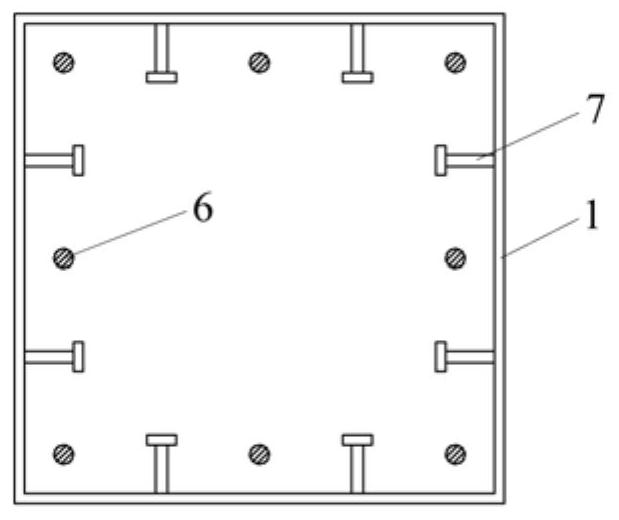

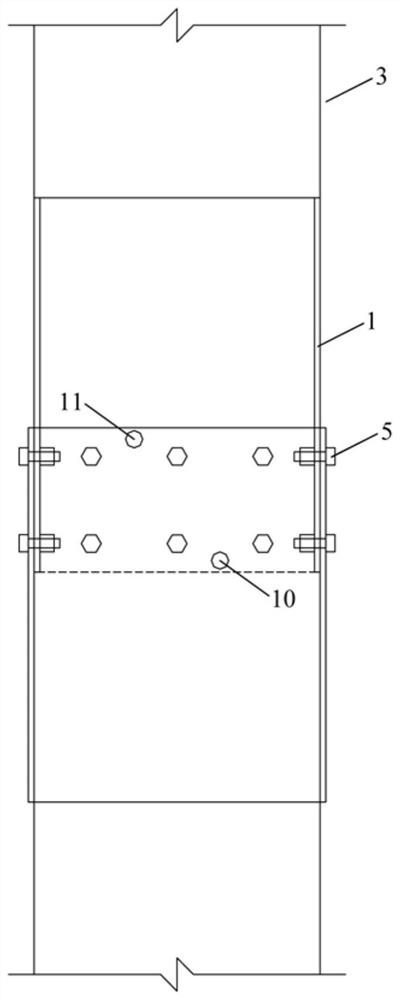

[0041] to combine Figure 1 to Figure 5 , Embodiment 1 provides a prefabricated concrete column box-shaped steel sleeve connection structure, including an upper precast concrete column 3, a lower precast concrete column 4, an upper precast concrete column box-shaped steel sleeve 1, a lower precast concrete column box Shaped steel sleeve 2, unilateral bolt 5, thin steel plate 13, longitudinal reinforcement 6, anchor plate 8, peg 7 and grouting material 9.

[0042] The box-shaped steel sleeve (that is, the upper precast concrete column box-shaped steel sleeve 1 in the figure and the lower precast concrete column box-shaped steel sleeve 2) and the precast concrete column (that is, the upper precast concrete column 3 in the figure and the lower precast concrete column Column 4) The inner surface of the concrete joint part should be welded with stud 7.

[0043]Bolt holes should be reserved for the part of the upper precast concrete column box-shaped steel sleeve 1 or the lower pre...

Embodiment 2

[0056] combine Figure 6 ~ Figure 8 , Embodiment 2 provides an assembled concrete shear wall box-shaped steel sleeve connection structure, including an upper precast concrete shear wall 23, a lower precast concrete shear wall 24, and an upper precast concrete shear wall box-shaped steel sleeve Tube 21, lower prefabricated concrete shear wall box-shaped steel sleeve 22, unilateral bolt 25, thin steel plate for plug joint 33, longitudinal reinforcement 26, anchor plate 28, stud 27 and grouting material 29.

[0057] The box-shaped steel sleeve (that is, the upper precast concrete shear wall box steel sleeve 21 in the figure and the lower precast concrete shear wall box steel sleeve 22) and the precast concrete shear wall (that is, the upper precast concrete shear wall in the figure) The inner surface of the concrete joint part of the shear wall 23 and the lower prefabricated concrete shear wall 24) should be welded with studs 27.

[0058] Bolt holes should be reserved for the pa...

Embodiment 3

[0071] combine Figure 9 ~ Figure 11 , this embodiment provides an assembled concrete beam box-shaped steel sleeve connection structure, including a right precast concrete beam 43, a left precast concrete beam 44, a right precast concrete beam box steel sleeve 41, a left side Prefabricated concrete beam box-shaped steel sleeve 42, unilateral bolt 45, thin steel plate 53, longitudinal reinforcement 46, anchor plate 48, stud 47 and grouting material 49.

[0072] The inner surface of the right side precast concrete beam box steel sleeve 41 or the left side precast concrete beam box steel sleeve 42 and the right side precast concrete beam 43 or the left side precast concrete beam 44 concrete joint part should be welded with studs 47 .

[0073] Bolt holes should be reserved for the parts of the box-shaped steel sleeves (numbers 41 and 42 in the figure) that are not in contact with the concrete of the precast concrete beams (numbers 43 and 44 in the figure).

[0074] A grouting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com