Vertical jacking construction method for tunnel inclined shaft entering main tunnel

A construction method, the technology of the front hole, applied in the direction of tunnels, tunnel linings, shaft linings, etc., can solve the problems of large consumption of temporary supports, difficulty in removing slag, and narrow construction work surface, so as to reduce the amount of temporary supports and the jacking steps Clear, clear, simple assembly and stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

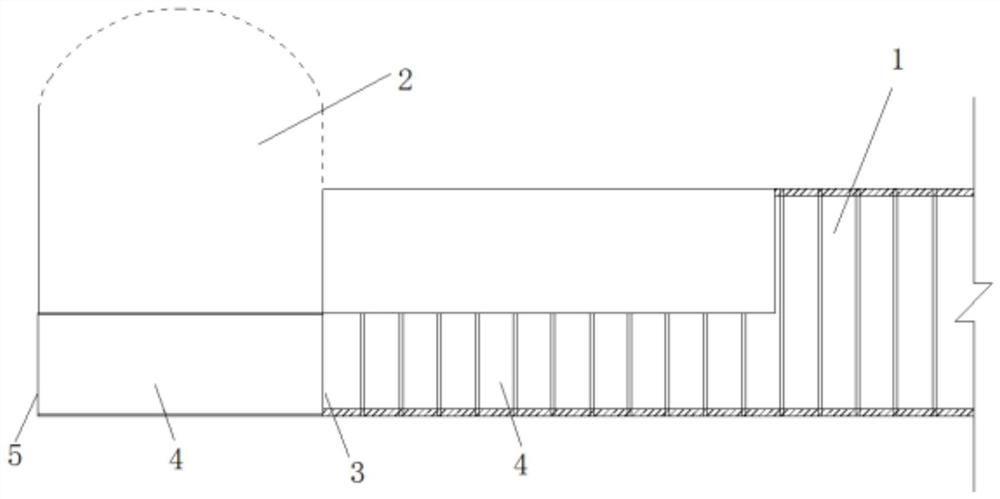

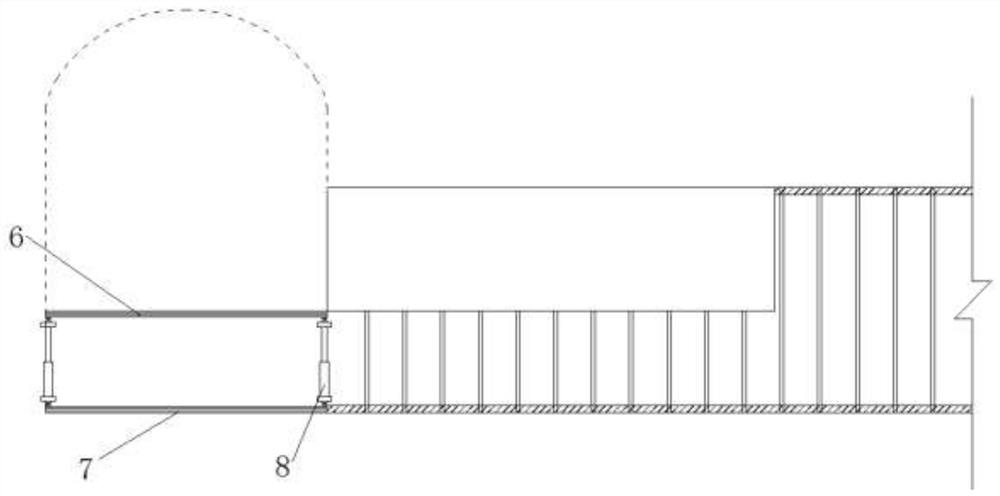

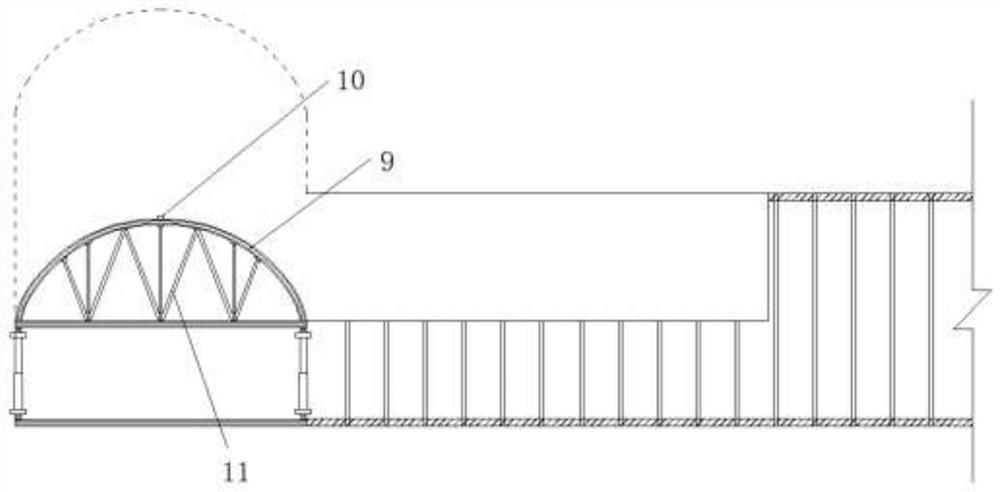

[0045] Taking the working condition below as an example of 6.3m x 5m inclined shaft 1 excavating into a 6.3m x 9.0m normal tunnel with a width x height of 6.3m x 9.0m, the vertical roof of the tunnel inclined shaft of the present invention will be described in conjunction with the accompanying drawings. liter construction method for further description, the construction method includes the following steps:

[0046] Step 1: Excavate the inclined shaft: Firstly, excavate the inclined shaft 1 to a distance of ten meters from the side wall I3 of the main tunnel 2 according to the common excavation method. The subsurface shall be treated with shotcrete sealing, and if necessary, grouting bolts shall be installed for reinforcement; then a rectangular pilot tunnel 4 shall be excavated until the side wall II 5 of the main tunnel. The height of the rectangular pilot tunnel is 2.75 meters lower than the height of the vault of the inclined shaft. With the excavation progress, the tempora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com