Pipeline flexible robot and control method thereof during moving in pipeline

A robot and flexible transmission technology, which is applied in the field of flexible robots, can solve the problems of difficult cleaning tools for curved pipes and insufficient pipe power, and achieves the effect of convenient wiring and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

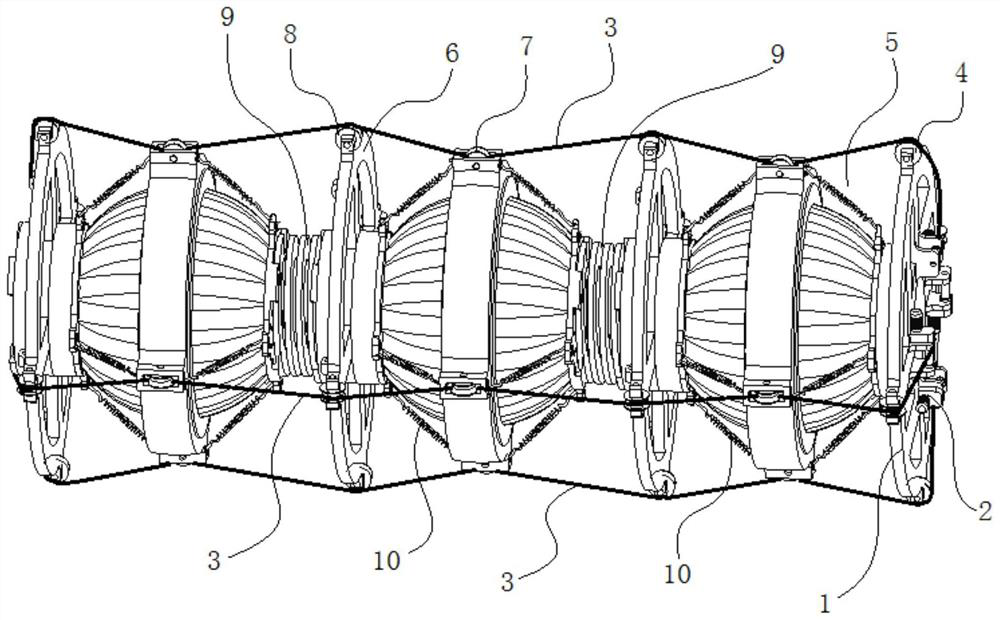

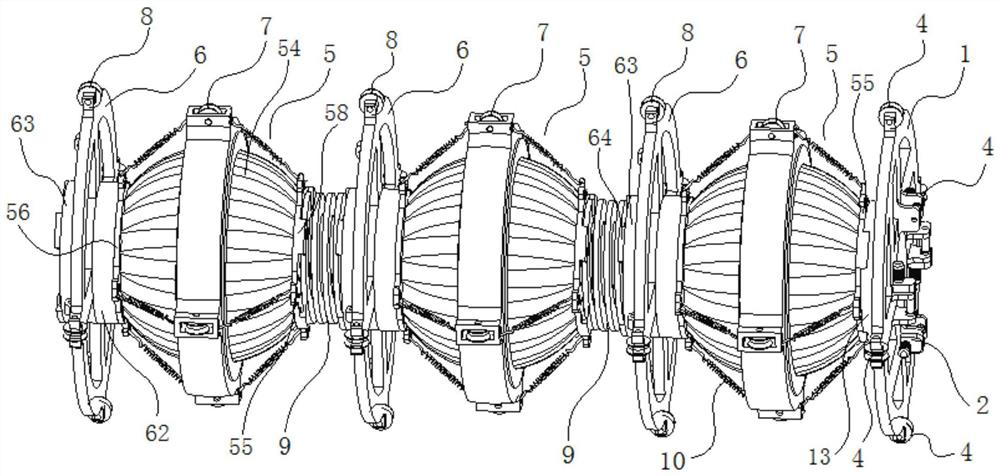

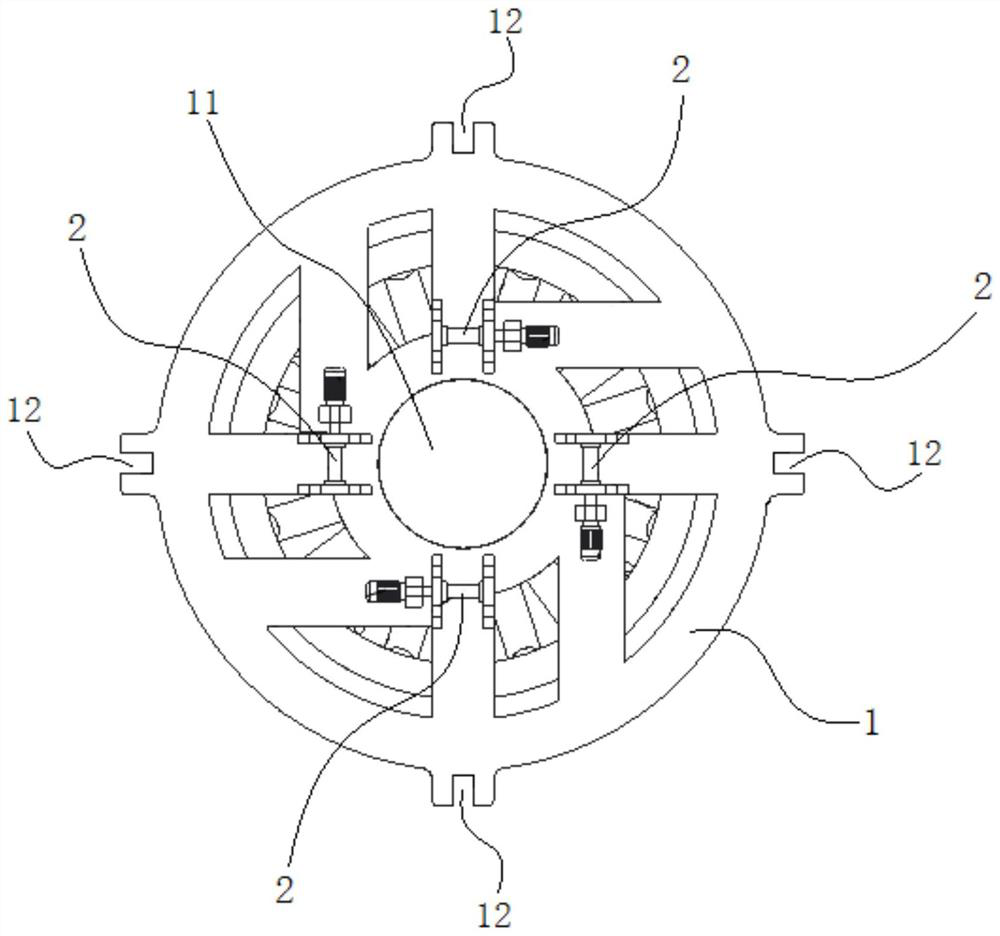

[0029] Such as Figure 1 to Figure 7The pipeline flexible robot shown includes a drive control device and a flexible transmission assembly, and the drive control device includes a drive mechanism, a pipeline detection sensor (not shown in the figure) and a controller (not shown in the figure).

[0030] The drive mechanism includes a drive support frame 1, four electric hoists 2, four ropes 3 and four first pulleys 4, the front end of the drive support frame 1 is provided with a drive installation platform 13, and four drive installation platforms are evenly arranged on the drive installation platform 13. The card slot, the center of the drive support frame 1 is provided with a first wire hole 11, and the edge of the drive support frame 1 is provided with four first pulley installation grooves 12 distributed in a cross shape (that is, the four first pulley installation grooves 12 are spaced apart from each other) 90° distribution), the four first pulleys 4 are respectively inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com