Drying device for bioengineering by utilizing air circulation principle

A bioengineering and drying device technology, applied in the direction of drying gas arrangement, granular material drying, heating device, etc., can solve the problems of low drying efficiency and drying effect, incomplete drying of particles, etc., and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

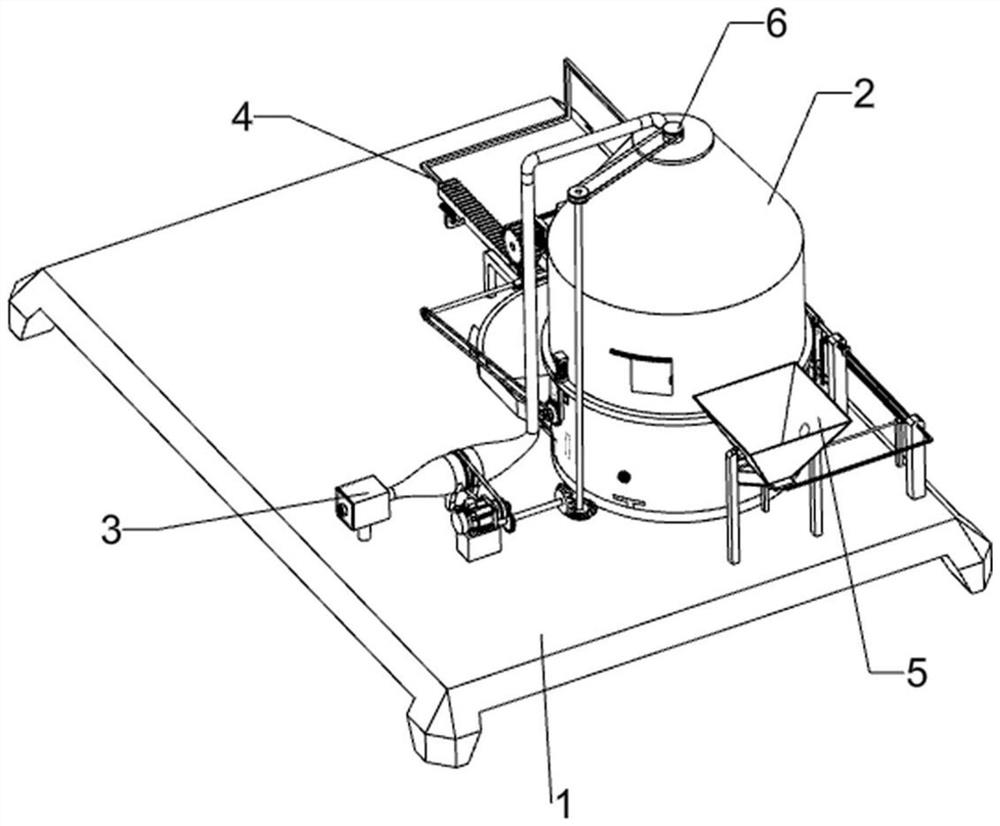

[0039] A drying device for bioengineering using the principle of air circulation, such as Figure 1-5 As shown, it includes a base 1 , a drying mechanism 2 and a blowing mechanism 3 , the base 1 is provided with a drying mechanism 2 , and the base 1 is provided with a blowing mechanism 3 .

[0040] When people need to use this device, first people will need to be dried granular matter is placed in the drying mechanism 2, then just can start the blowing mechanism 3, and the blowing mechanism 3 operates and then draws hot air into the drying mechanism 2, thereby Dry the granular matter in the drying mechanism 2, and when the drying is completed, people can close the blower mechanism 3, so that the granular matter can be dried quickly, and when people do not need to use the device, close the blower mechanism 3 That's it.

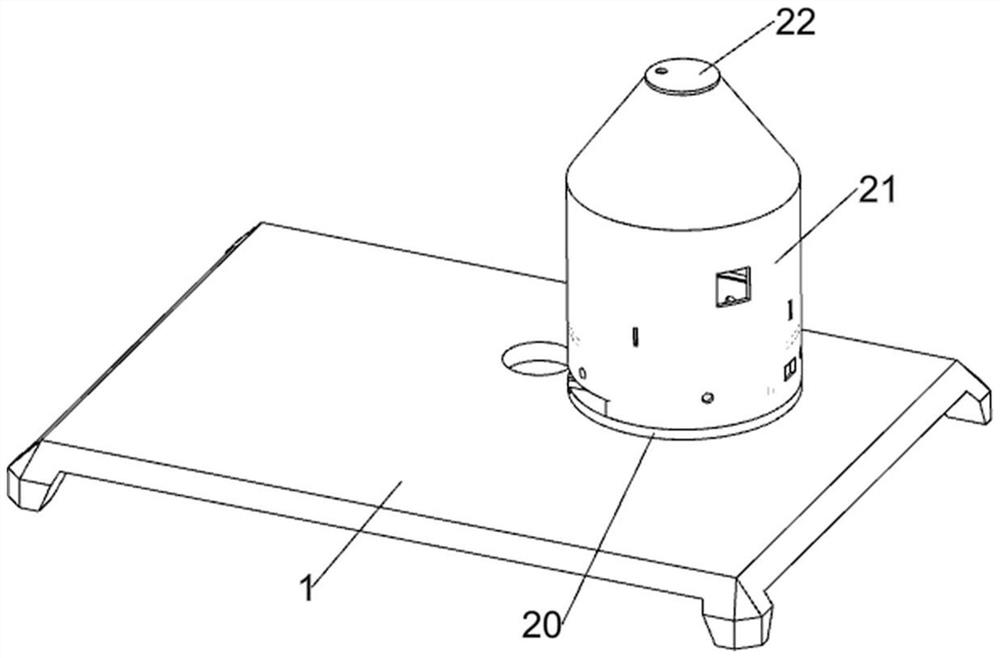

[0041] Drying mechanism 2 includes mounting plate 20, tank body 21 and tank cover 22, base 1 top right rear side is provided with mounting plate 20, is provid...

Embodiment 2

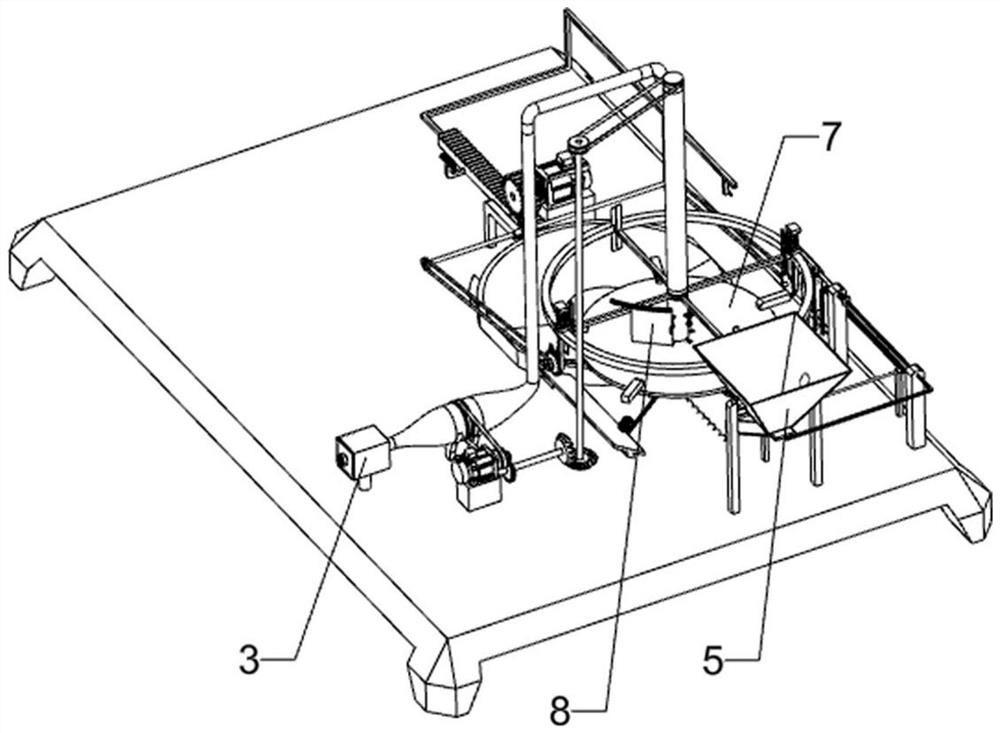

[0045] On the basis of Example 1, such as figure 1 , Figure 5-Figure 16 As shown, it also includes a blanking mechanism 4. The blanking mechanism 4 includes a second servo motor 40, a first spur gear 41, a first rack 42, a first slide rail 43, a first slider 44, and a second slider. 45. The first spring 46, the first connecting block 47, the first slide bar 48, the second spring 49 and the limit block 410, the rear side of the top of the base 1 is provided with a second servo motor 40, and the output shaft of the second servo motor 40 is provided with There is a first spur gear 41, a first slide rail 43 is symmetrically arranged between the mounting plate 20 and the tank body 21, and a first slide block 44 is slidably arranged between the first slide rail 43, and the bottom of the first slide block 44 is connected to the base 1 are provided with round holes, the left side of the first slider 44 is provided with a first rack 42, the bottom of the first slider 44 is slidingly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap