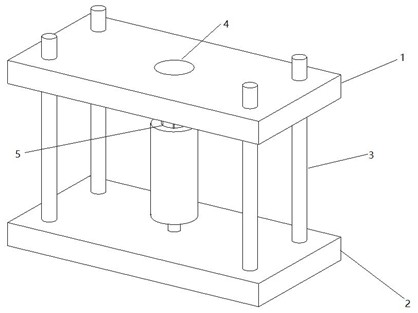

Dual-mode sample preparation and demolding method for unsaturated soil triaxial experiments

A technology of triaxial experiment and sample making mold, which is used in the preparation, sampling, measuring device and other directions of test samples, which can solve the problems such as the calculated density is not the actual density, and the uncontacted end of the sample end is loose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare a soil sample with a certain moisture content according to the sample required by the test, put it in a plastic bag and put it in an airtight container for 24 hours, then take it out for use.

[0035] According to the required sample size and quality, weigh the soil samples for later use.

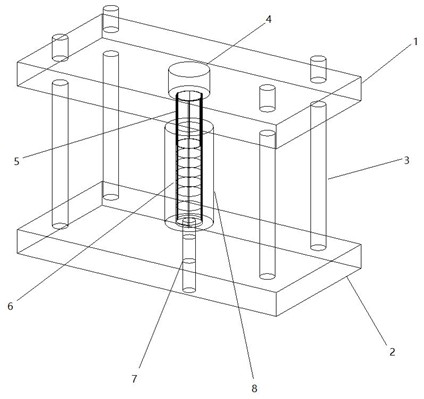

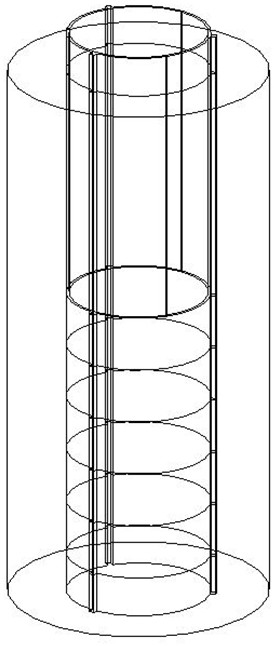

[0036] The number of pads in the sample cylinder is configured according to the height of the sample, and a layer of Vaseline is evenly applied to the inner wall of the convex three-lobed intima.

[0037] Pour the soil required for the production time into the double-mold cylinder for making the test piece, and smooth the surface of the soil.

[0038] Use a universal testing machine or a jack to compact the soil with static pressure to a certain required height of the specimen.

Embodiment 2

[0040] The compacted test piece is placed on the demoulding machine, and the bulldozer of the demoulding machine should be aligned with the center of the solid pad inside the test piece cylinder.

[0041] Then turn on the demoulding machine, the bulldozer rises slowly, and pushes the block of the test piece cylinder upwards along the inner membrane wall at a constant speed.

[0042] The convex three-lobe inner mold is gradually pushed out to remove the three-lobe inner membrane, so as to obtain a complete, non-destructive and highly accurate soil specimen.

[0043] In this process, high-quality soil specimens can be obtained under the premise of ensuring the test speed, which provides a guarantee for the later test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com