Experimental device for ultrasonic detection of shale hydration microcrack propagation characteristics under high-temperature and high-pressure water circulation effect

A high-temperature, high-pressure, experimental device technology, applied in measurement devices, using sonic/ultrasonic/infrasonic waves to analyze solids, strength characteristics, etc., can solve the problems of expensive equipment, complicated operation steps, time-consuming and labor-intensive, etc. Experimental accuracy, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

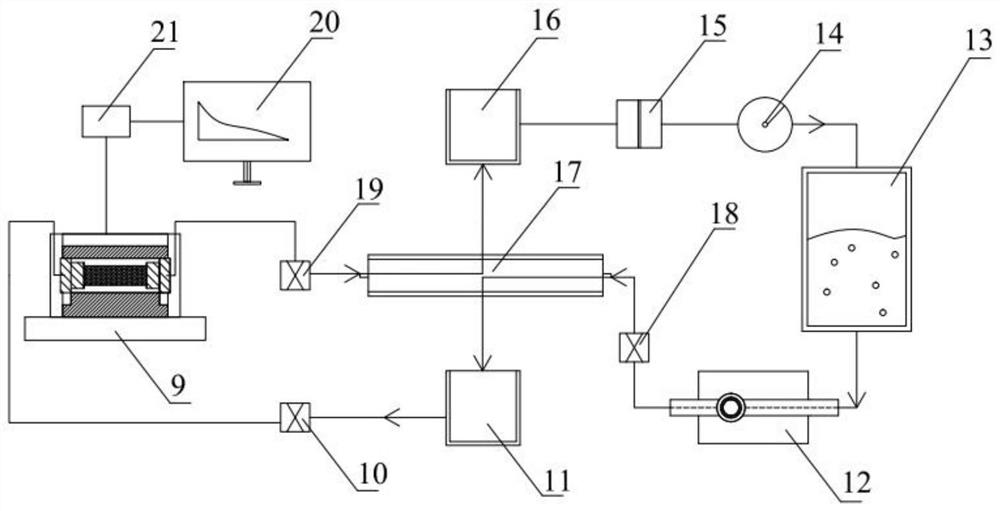

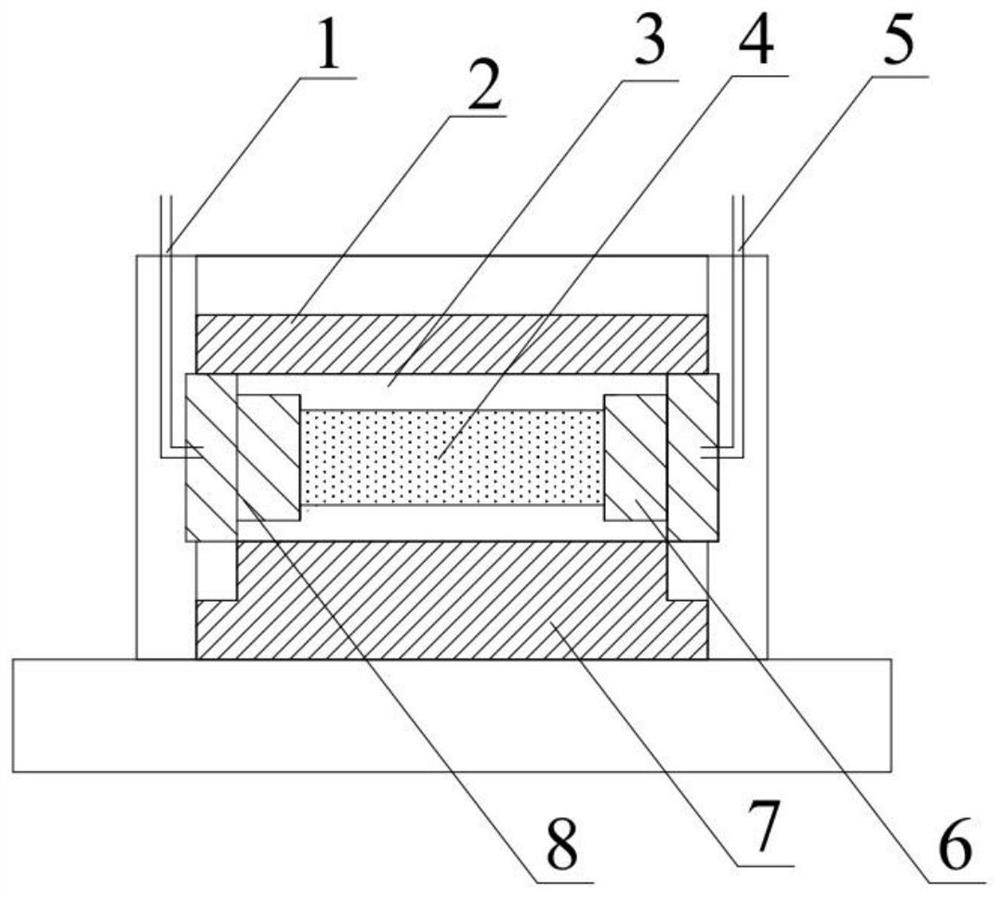

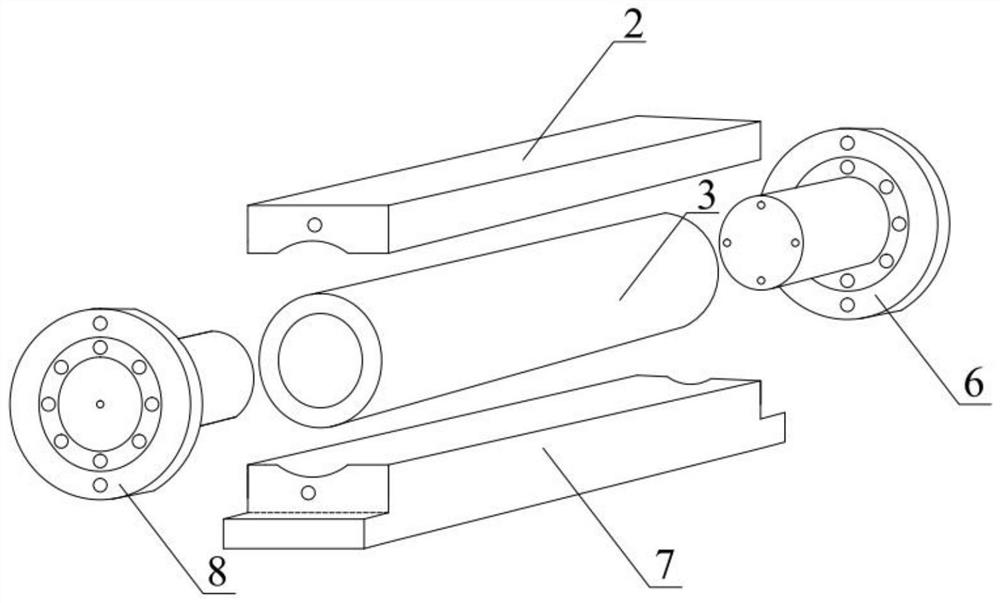

[0032] Such as figure 1As shown, an ultrasonic testing device of the present invention for the expansion characteristics of shale hydration micro-cracks under the action of high-temperature and high-pressure water circulation is composed of a high-temperature and high-pressure hydration reaction kettle 9, a water circulation injection control valve 10, a heating device 11, a high-pressure pump 12, and a water tank 13. Flow meter 14, back pressure regulator 15, cooling device 16, temperature changer 17, safety control valve 18, water circulation control valve 19, computer 20 and ultrasonic flaw detector 21. Among them, the water circulation water injection port 1 is connected with the high-pressure pump 12, the water injection pressure is controlled by the water circulation water injection control valve 10, and the water injection temperature is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com