Water sample treatment system

A technology for processing systems and water samples, applied in the field of water treatment, can solve problems such as low degree of automation of organic matter detection devices in water, inability to process systems, etc., and achieve the effects of ensuring extraction efficiency and experimental accuracy, solving water inflow, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

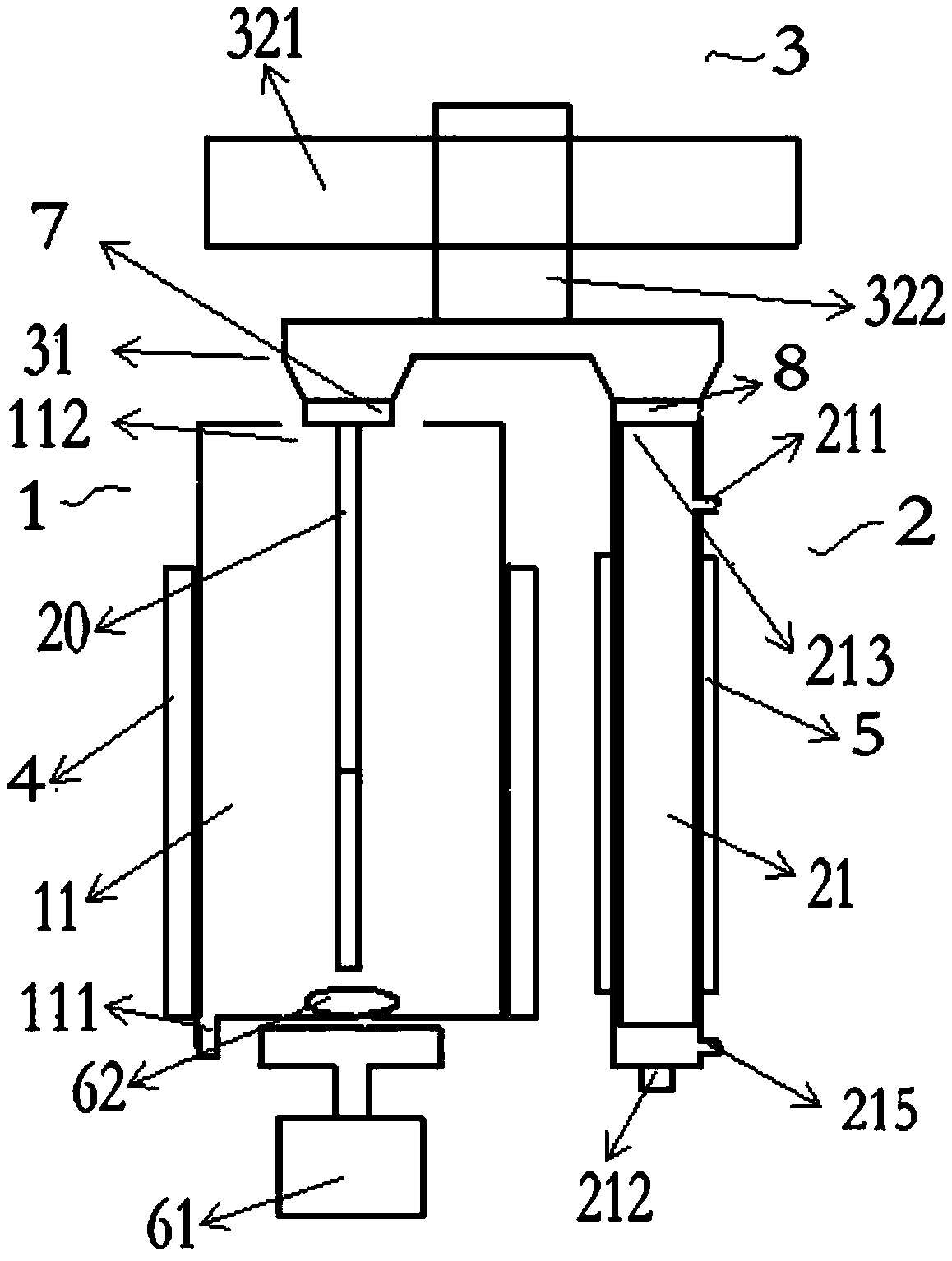

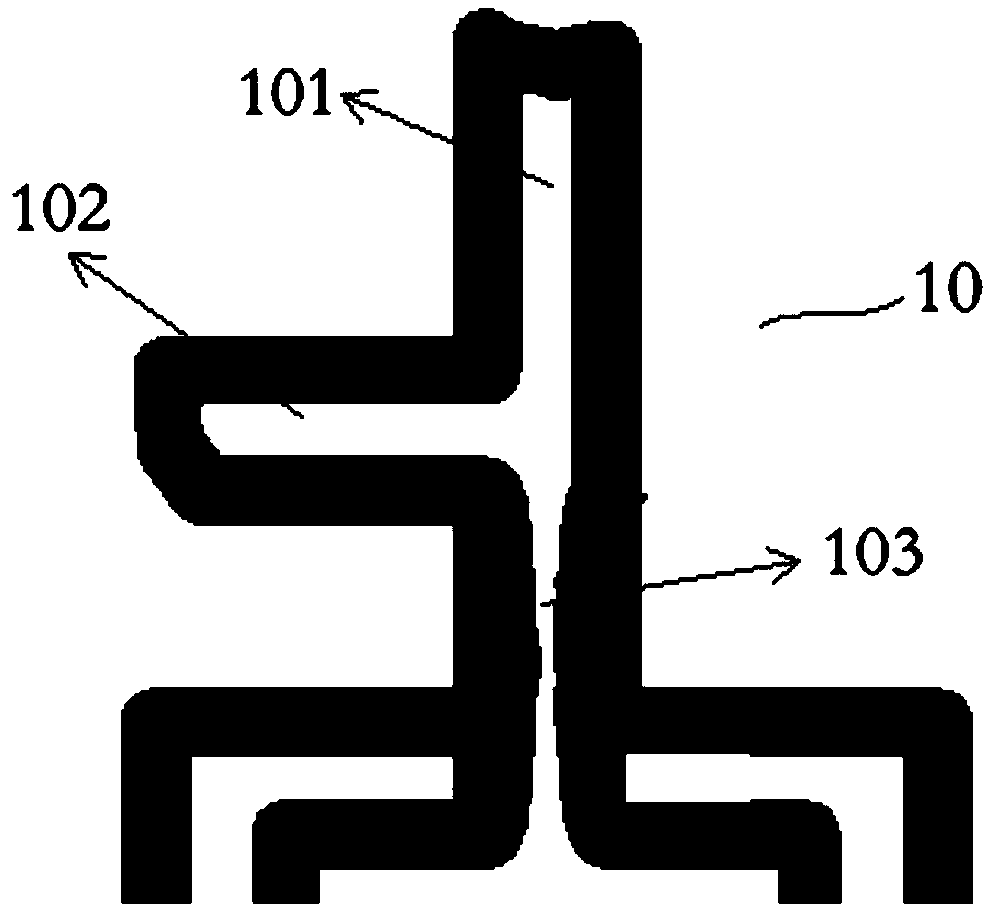

[0039] Such as figure 1 As shown, the tops of the extraction mechanism 1 and the analysis mechanism 2 in this embodiment are at the same level, and the linkage mechanism 3 is located at the top of the extraction mechanism 1 and the analysis mechanism 2 . The transportation part of the linkage mechanism 3 in this embodiment can move horizontally between the first chamber 11 and the second chamber 21, and drive the extract 20 held by the installation part 31 into the first chamber 11 for extraction, and then into the The second chamber 21 performs analysis. Specifically, the water sample inlet and outlet 111 in this embodiment is arranged at the bottom of the first chamber 11, the first extract inlet and outlet 112 is arranged at the top; the carrier gas inlet 211 is arranged on the side of the second chamber 21, and the carrier gas outlet 212 is arranged At the bottom, a second extract port 213 is located at the top. The first extract port 112 is level with the second extract...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

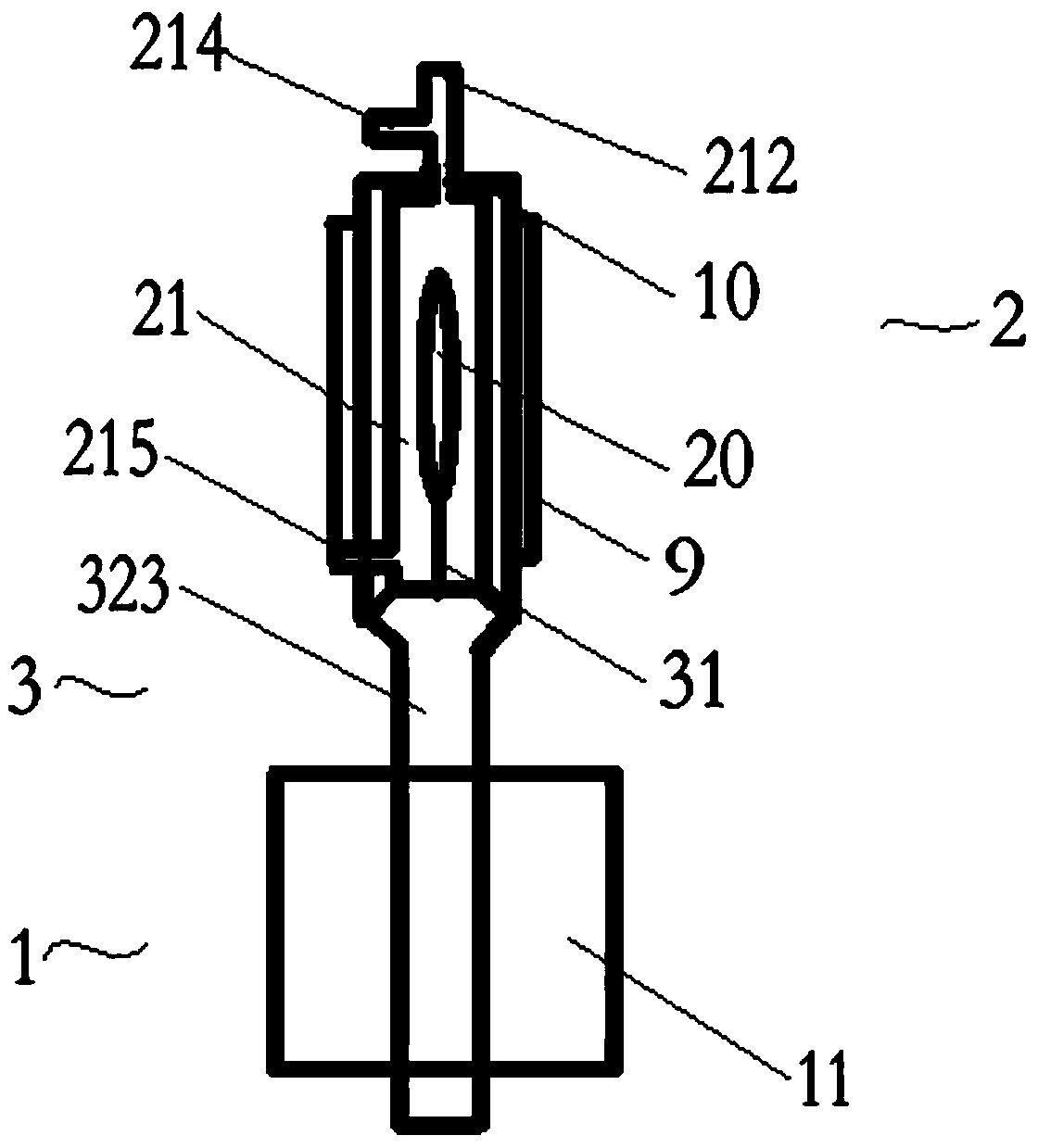

[0049] The extraction mechanism 1 and the analysis mechanism 2 in Embodiment 1 are arranged horizontally, and the extraction mechanism 1 and the analysis mechanism 2 in this embodiment are arranged vertically.

[0050] The analysis mechanism 2 in this embodiment is located above the extraction mechanism 1 and is connected through a linkage mechanism 3 . In this embodiment, the first extract inlet and outlet 112 is located at the top of the first chamber 11, the second extract inlet and outlet 213 is located at the bottom of the second chamber 21, the transport parts can move up and down, and the extract 20 is located between the extraction mechanism 1 and the analysis mechanism. 2 movement betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com