Interferometer and method for producing an interferometer

An interferometer and component technology, which is applied in the field of interferometers and used in the manufacture of interferometers to achieve the effect of reducing the risk of occlusion and improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

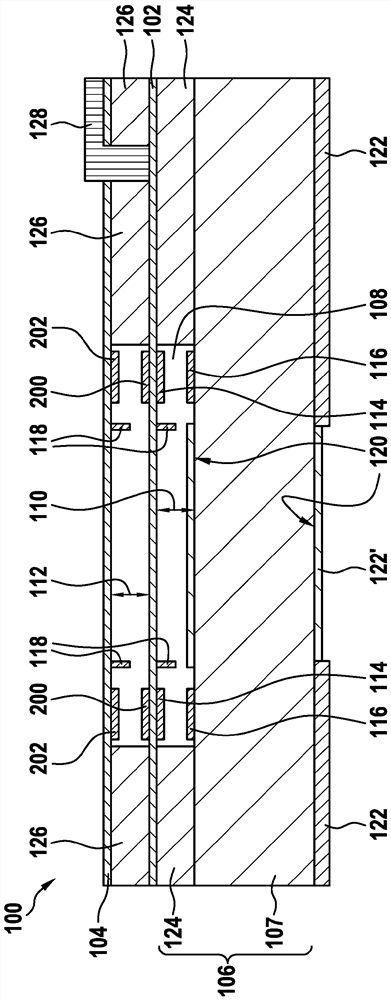

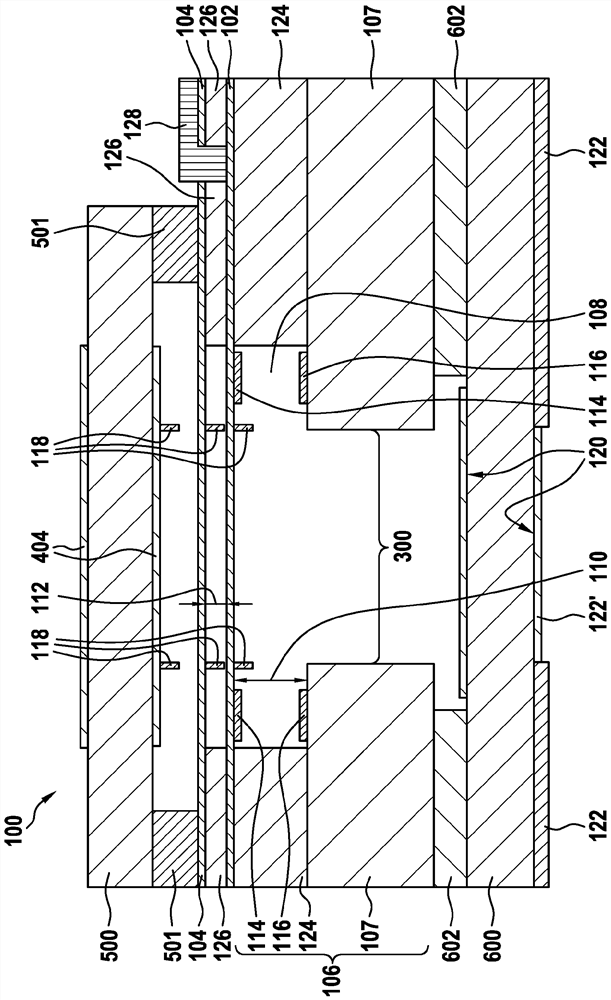

[0048] figure 1 A schematic diagram of an interferometer 100 according to an exemplary embodiment is shown. Interferometer 100 comprises a first mirror element 102 and a second mirror element 104 arranged opposite first mirror element 102 with a variable mirror pitch. The first mirror element 102 , here for example the lower mirror, is arranged on the holding element 106 opposite the actuating recess 108 of the holding element 106 and delimits an actuating gap 110 therewith, wherein the The holding element is based here by way of example on a base body (wafer) 107 and additional layers which will be described in more detail below. A cross-section of a Fabry-Perot interferometer is shown as an example, for which the actuation takes place electrostatically via the actuation slit 110, wherein the actuation The initial pitch of the slots 110 can be adjusted independently of the mirror pitch. The second mirror element 104 , here for example the upper mirror, defines an optical g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com