Control method of integrated interferometer

A control method and interferometer technology, which is applied in the field of integrated circuit equipment manufacturing, can solve the problems of X-direction position deviation and measurement axis installation error, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

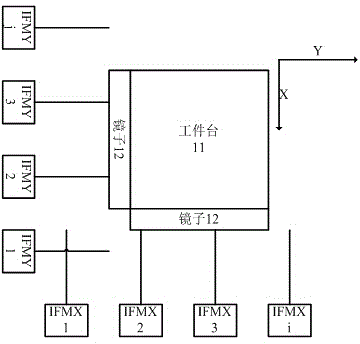

[0036] Single interferometer control scheme, on the travel of the workpiece table / mask table, different areas are controlled by different interferometers, and the switching of the two interferometers is completed at the intersection of the two interferometer control areas, such as Image 6 As shown, for the measurement system composed of three interferometers, the weight is 1 in the area controlled by each interferometer, and the weight is 0 in other areas.

[0037] Consider the scheme of switching between two interferometers, set a switching area in the common control area of the two interferometers, in this area, assign the weight factors of the two interferometers in the form of multi-order functions, and finally get the stage position is calculated by weighting the measured values of the two interferometers, such as Figure 7 As shown in the example, when located in the switching region, the weight factor of one interferometer gradually decreases from 1 to 0, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com