An ultra-precise measurement platform

An ultra-precise measurement and platform technology, which is applied in the direction of measuring devices, point coordinate measurement, electromagnetic measuring devices, etc., can solve the problems of floating measurement platform, inability to guarantee the rigidity of the measurement platform, and high price, so as to prevent air shock and achieve high precision Effects of motion and measurement, improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

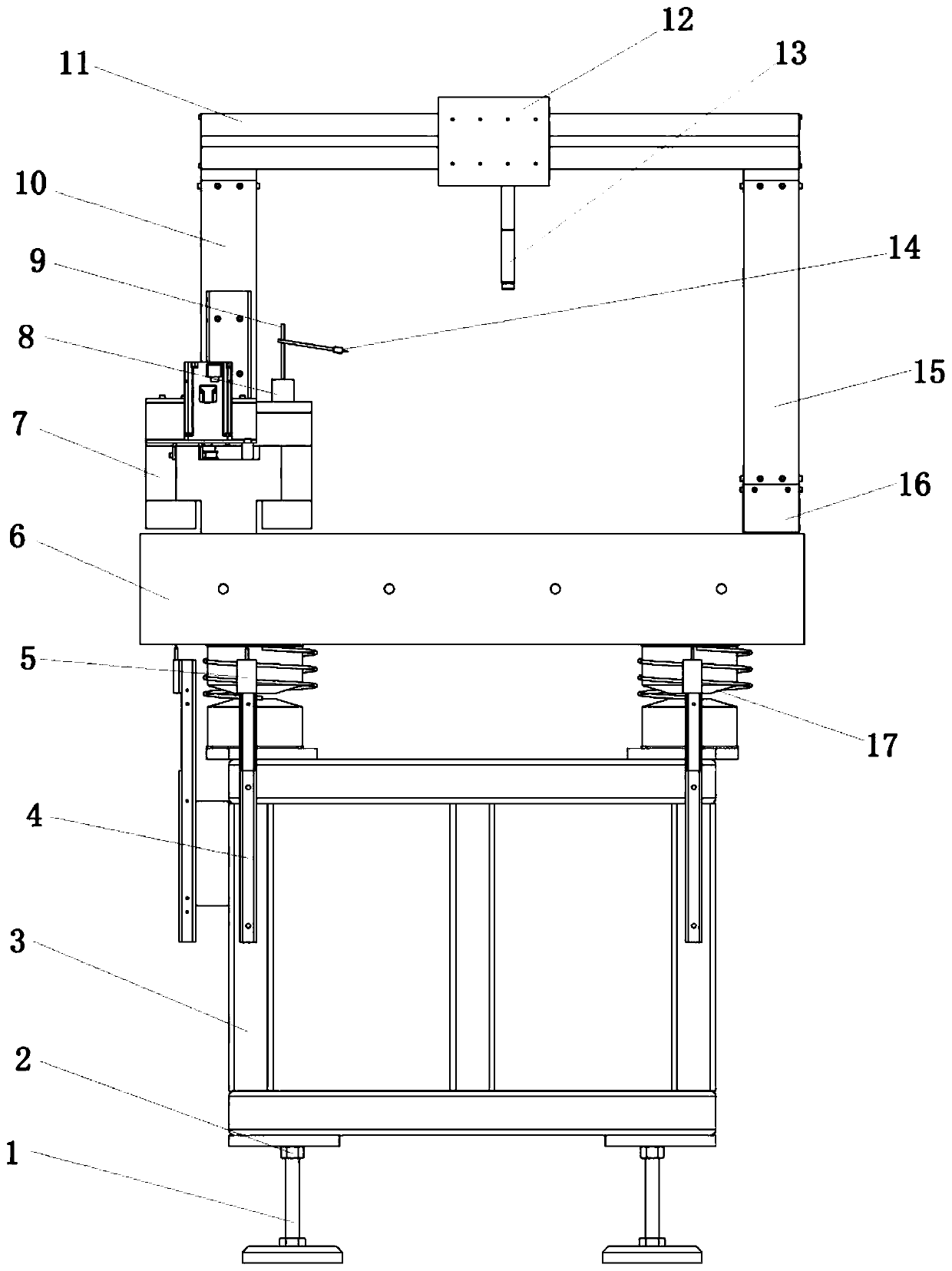

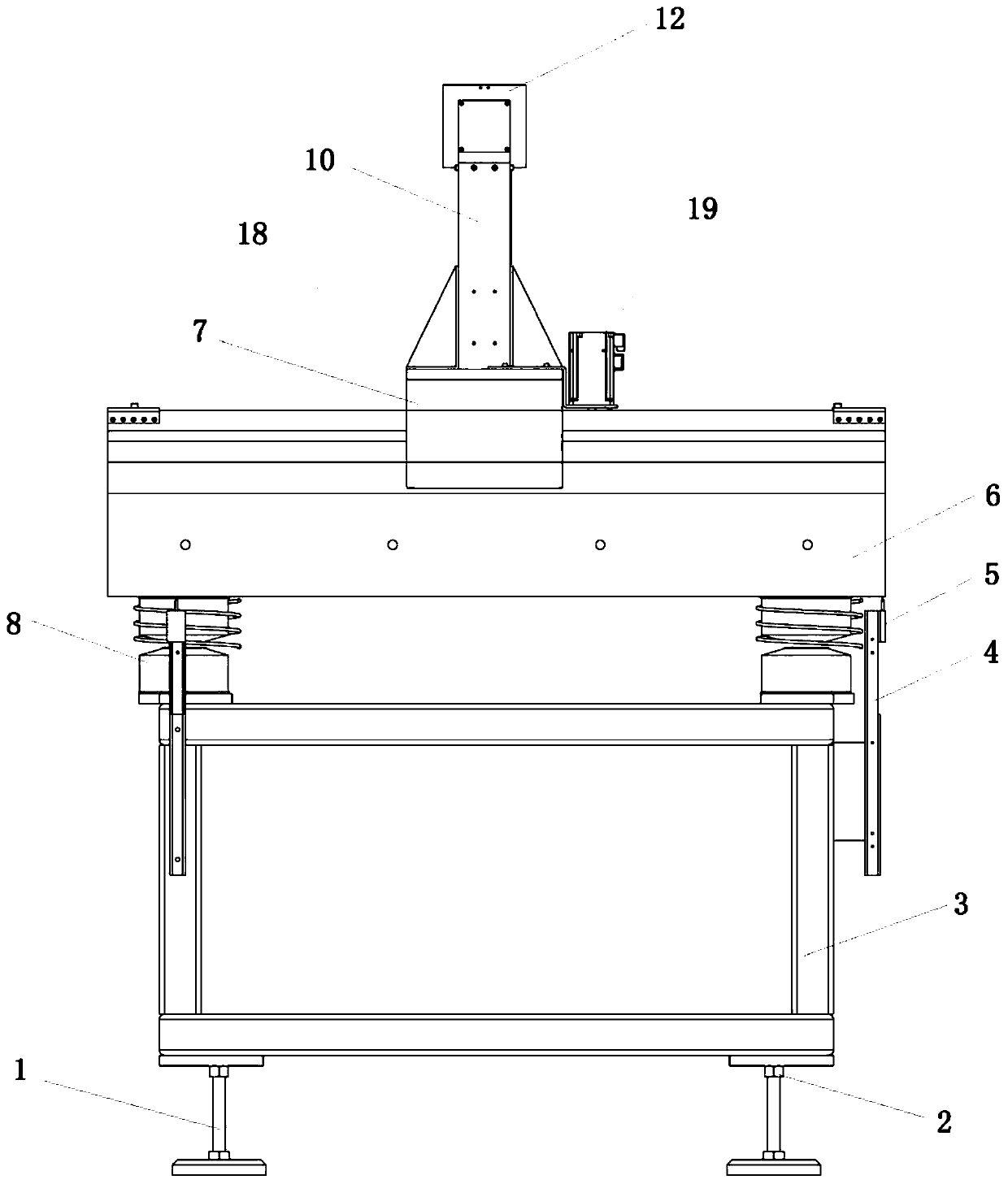

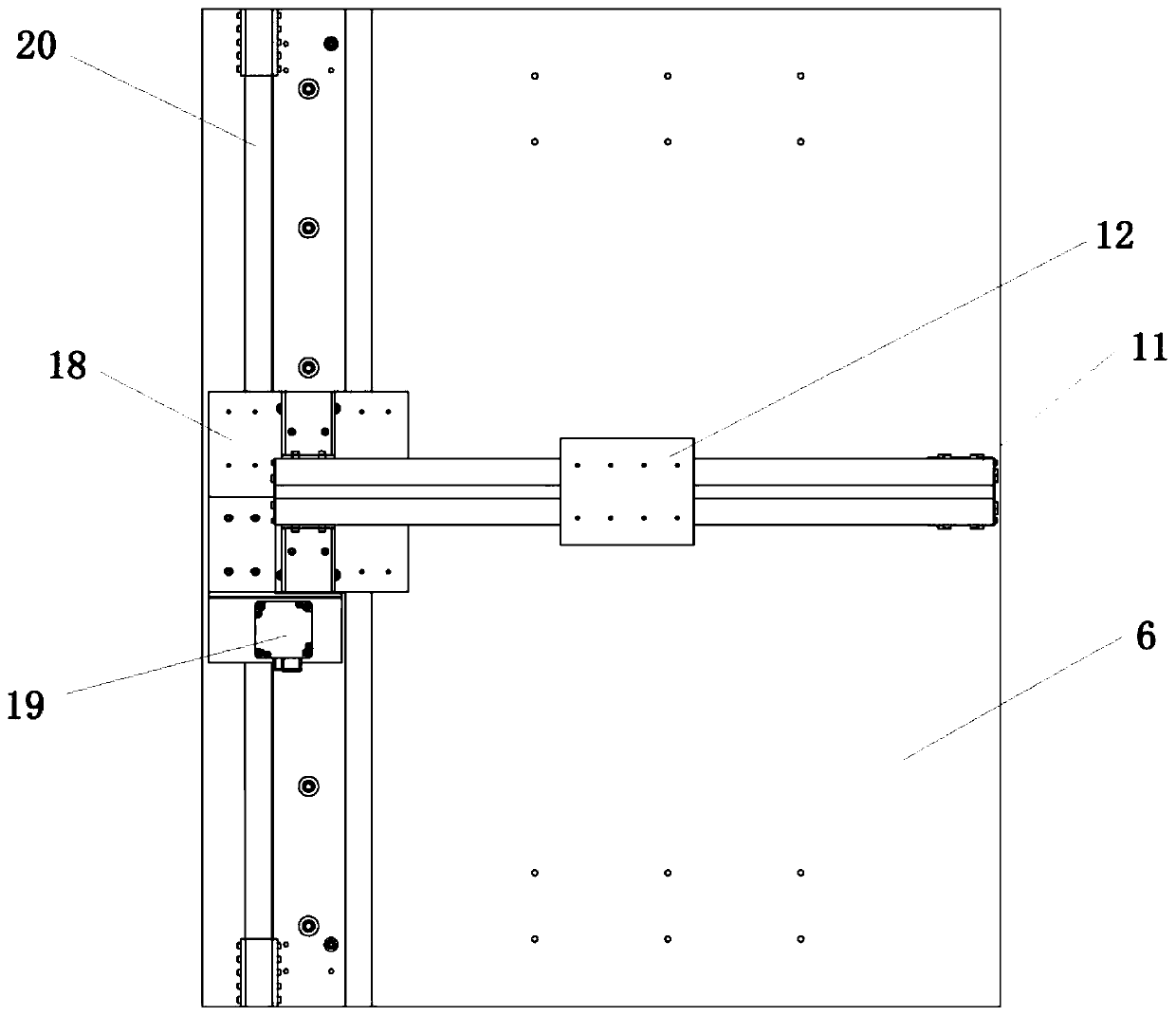

[0030] Such as Figure 1~3As shown, an ultra-precision measurement platform includes a frame assembly, a deadlock nut, an anchor adjustment screw, a bracket, a potentiometer sensor, a magnetic levitation assembly, a granite platform, an X-axis air bearing guide rail assembly, a first column, a second Columns, beams, Y-axis air bearing guide rail components, high-precision sensors, magnetic suction devices, adjustment rods, micrometers and central processing units, wherein the frame components are welded by iron square tubes, and the feet are adjusted The screw is set on the bottom of the rack assembly, the deadlock nut is set on the foot adjustment screw and close to the bottom of the rack assembly; the potentiometer sensor is set on the bracket, and the bracket is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com