Quantitative detection device and detection method for chromatic aberration of high magnification objective lens

A quantitative detection, high-magnification objective lens technology, applied in the direction of testing optical performance, etc., can solve problems such as high cost, high error control requirements, and impact on judgment results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

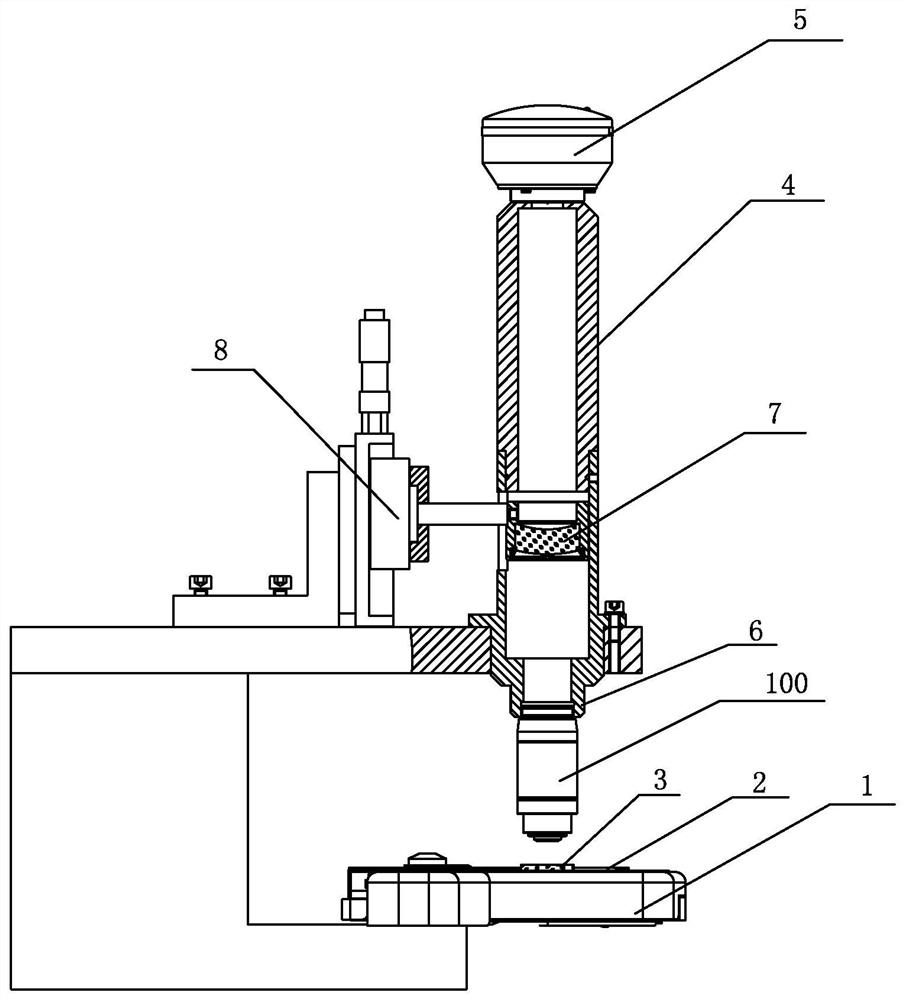

[0025] Example: such as figure 1 As shown, a quantitative detection device for the chromatic aberration of a high-magnification objective lens includes a red, green, and blue light source 1, an adjustable stage 2, a target 3, and an observation tube 4 arranged in sequence. On the adjustment stage 2, the wavelength of the green light source in the tri-color light source 1 is 546.07nm, the wavelength of the blue light source is 479.99nm, the wavelength of the red light source is 643.85nm, the target 3 is opaque on the side, and the middle is set Observation sheet for translucent cross-hair target image (or observation sheet for small hole target image). The end of the observation tube 4 away from the target 3 is provided with a camera 5, and the end of the observation tube 4 close to the target 3 is provided with an objective lens mounting structure 6. The observation tube 4 is provided with an observation mirror 7 that can move along the axis of the observation tube 4, and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com