Mulching film laying device for crop heat preservation in agricultural production

A technology for laying devices and crops, which is applied in plant protection, plant protection covers, botanical equipment and methods, etc., can solve the problems of large manpower input, difficulty in laying, and increased agricultural production costs, so as to achieve good use effect and good film laying easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

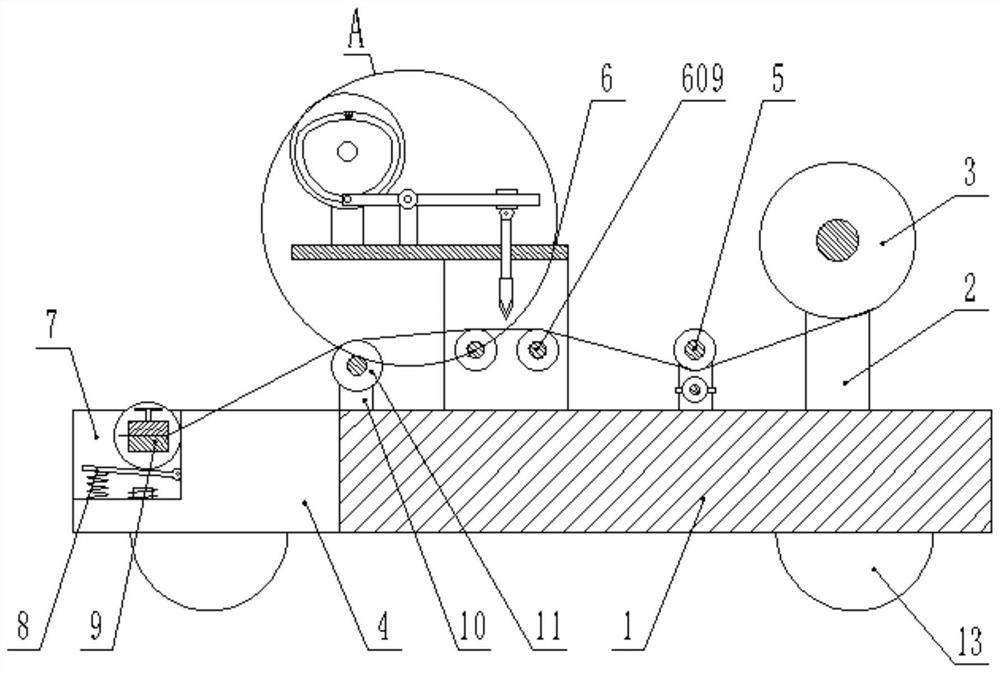

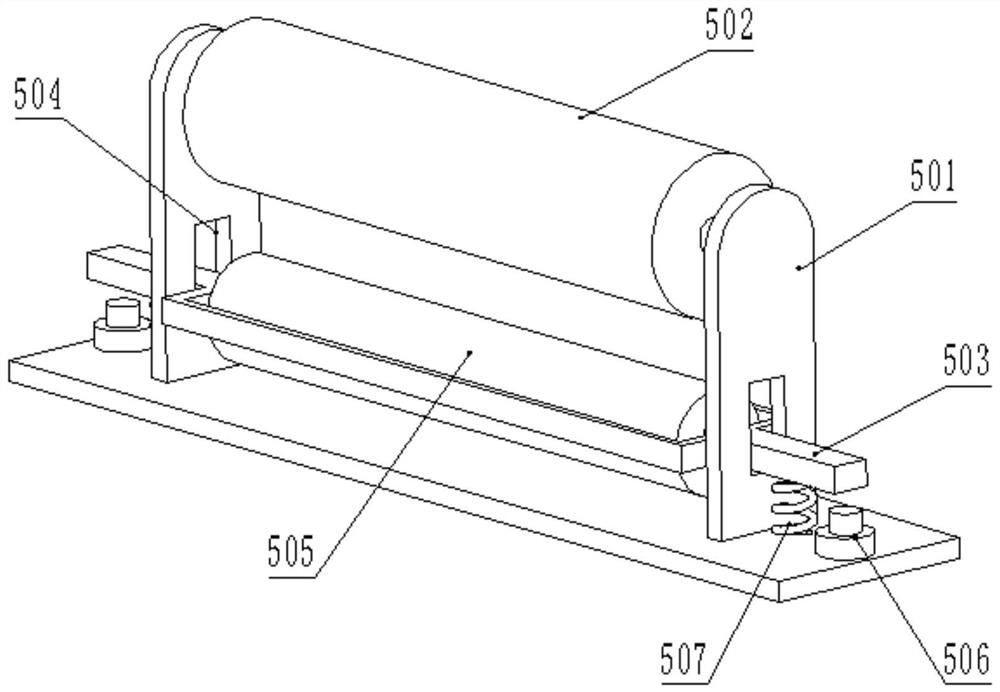

[0029] Example 1: Please refer to figure 1 , a mulch laying device for crop heat preservation in agricultural production, comprising a base 1 and a support column 2, the support column 2 is fixedly connected to the upper right end of the base 1, the upper end of the support column 2 is rotatably connected to an installation roller 3, and the left end of the base 1 has a gap 4 , the base 1 is provided with a locking mechanism 5, the locking mechanism 5 is located on the left side of the support column 2, the left side of the locking mechanism 5 is provided with a cutting mechanism 6, the cutting mechanism 6 is fixedly connected to the base 1, and the gap 4 An installation groove 7 is provided on the front and rear side base 1, and a limit component 8 is arranged in the installation groove 7, and a delivery component 9 is arranged on the limit component 8;

[0030] see figure 1 , the base 1 on the right side of the notch 4 is fixedly connected to the mounting plate 10, the moun...

Embodiment 2

[0042] Embodiment 2: This embodiment is a further improvement on the previous embodiment: please refer to figure 1 , the front and rear sides of the base 1 are provided with bilaterally symmetrical walking wheels 13 .

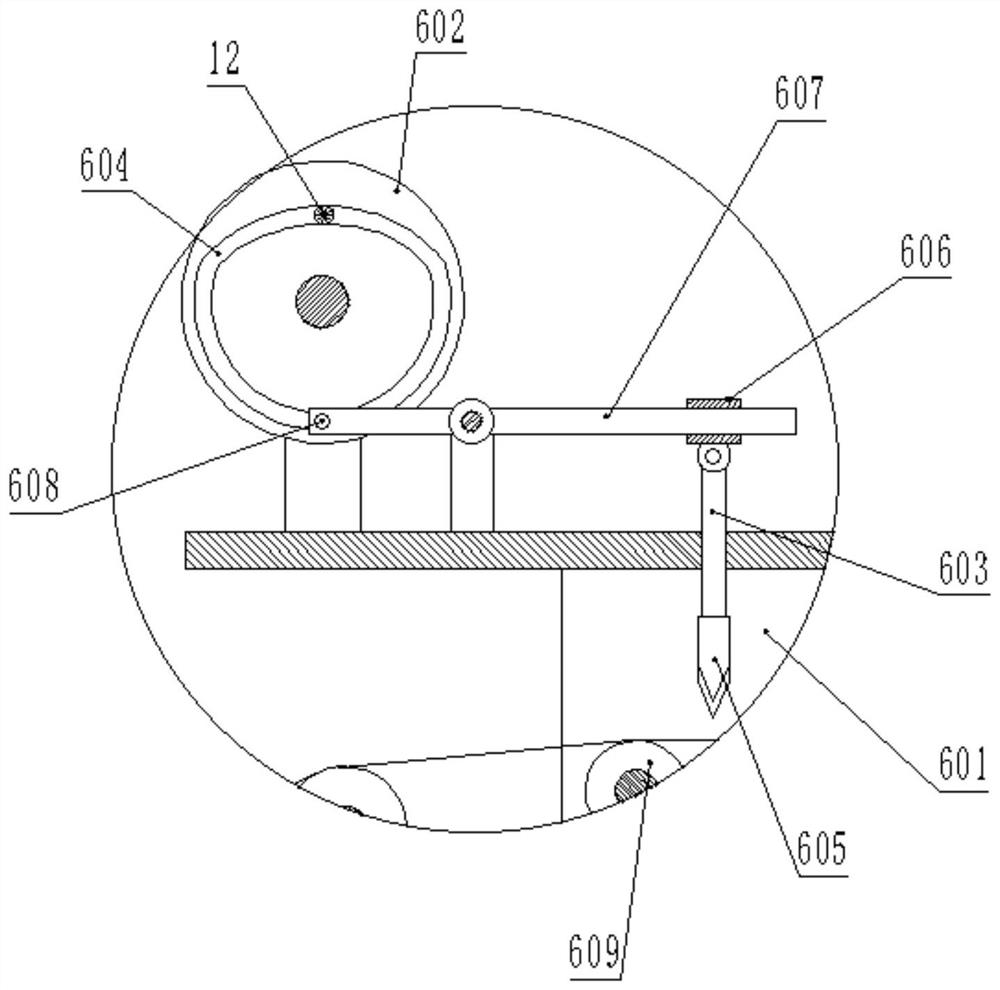

[0043] The working principle of the present invention is: install the film roll on the installation roller 3 of the support column 2, pass one end of the film continuously through the locking mechanism 5 and the cutting mechanism 6, adjust the pressure plate 902 through the fastening bolt 904, and fix one end of the film on the On the delivery component 9, when the device is working, at the starting point of the work, the second electromagnet 803 in the limit component 9 is energized, so that the seesaw 801 rotates counterclockwise, the delivery component 9 falls off from the device, and the device moves forward to pull and lay the mulch , after the laying of the film is completed, the rotation of the turntable 602 in the cutting mechanism 6 drives the swing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com