Reducing spinning method for controlling shape precision of straight cylinder piece

A straight cylinder and straight cylinder technology, which is applied in the field of diameter-reducing spinning to control the shape accuracy of straight cylinder parts, can solve the problems of excessive shape accuracy, no process plan, and loss of the foundation of cylindrical spinning shape accuracy control, etc., to achieve high precision Spinning, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

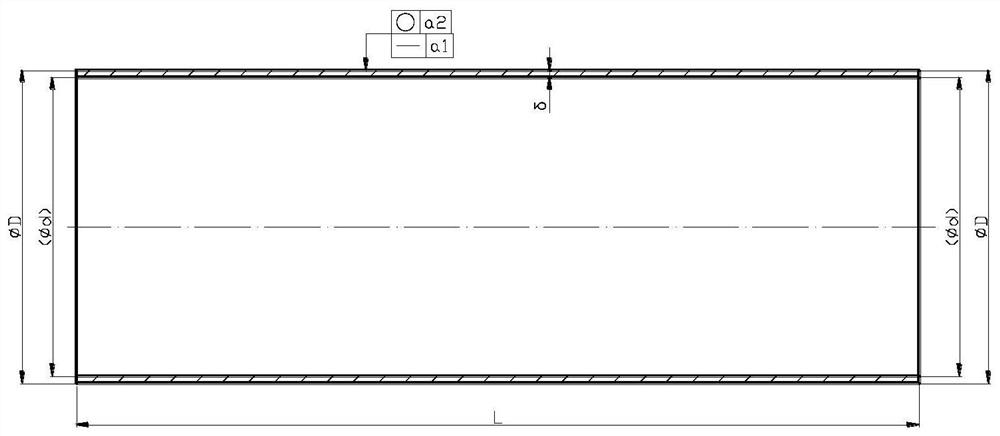

[0036] refer to figure 1 As mentioned above, the shape accuracy in this embodiment includes straightness a1 and roundness a2 within the entire length of the cylinder.

[0037] Concretely adopted process method steps are as follows:

[0038] Step 1: Set the spinning diameter expansion amount △δ, the spinning diameter expansion amount refers to the inner diameter of the straight cylinder and the bilateral clearance of the spinning die;

[0039] According to the inner diameter of the straight cylinder to be processed, the amount of spinning diameter expansion △δ is selected. The reference principle is: when the inner diameter of the straight cylinder φd≤100, the spinning diameter expansion amount △δ is 0.10-0.20mm; when the inner diameter of the straight cylinder φd>100-300, the spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com