Tobacco box overturning control method

A technology of overturning control and box, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of heavy tobacco leaves, low work efficiency, easy damage to inner boxes and tobacco leaves, etc., and achieve fast and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

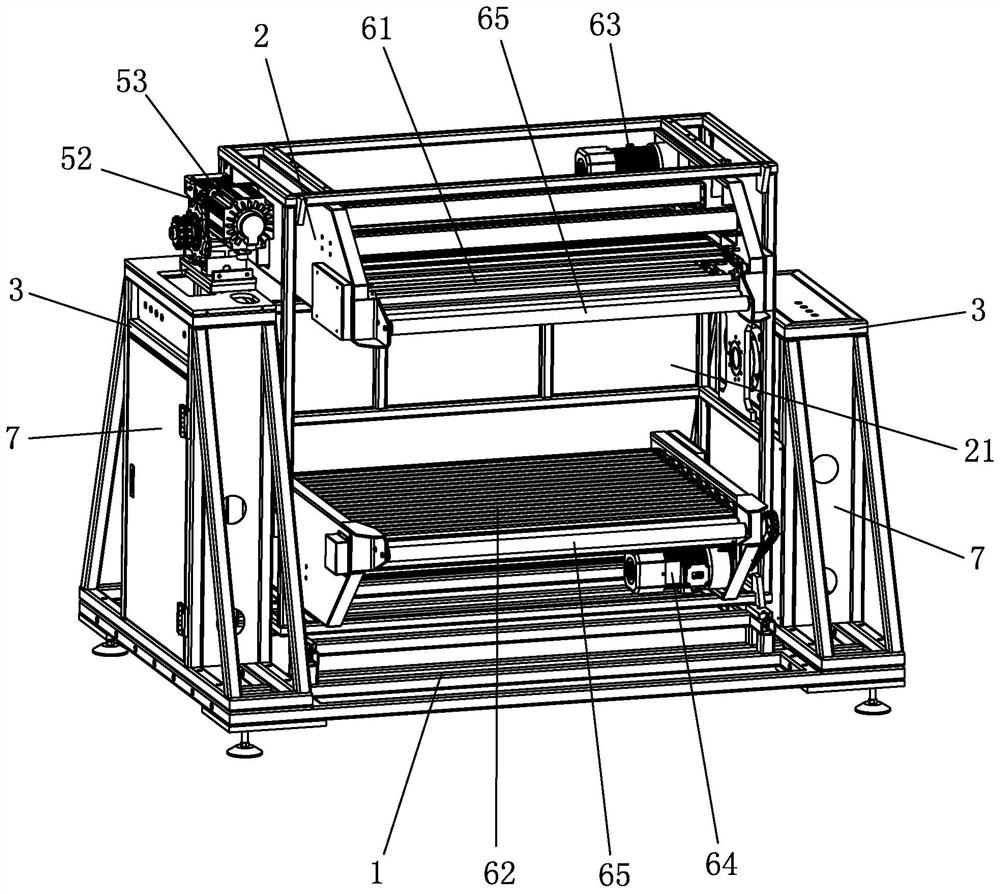

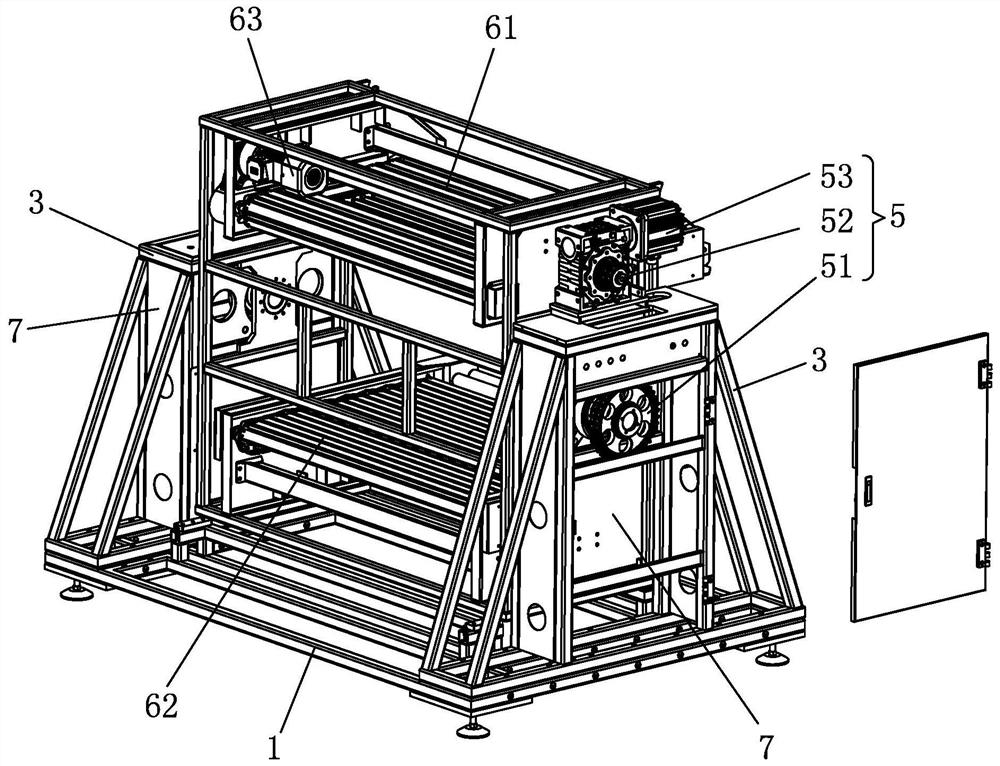

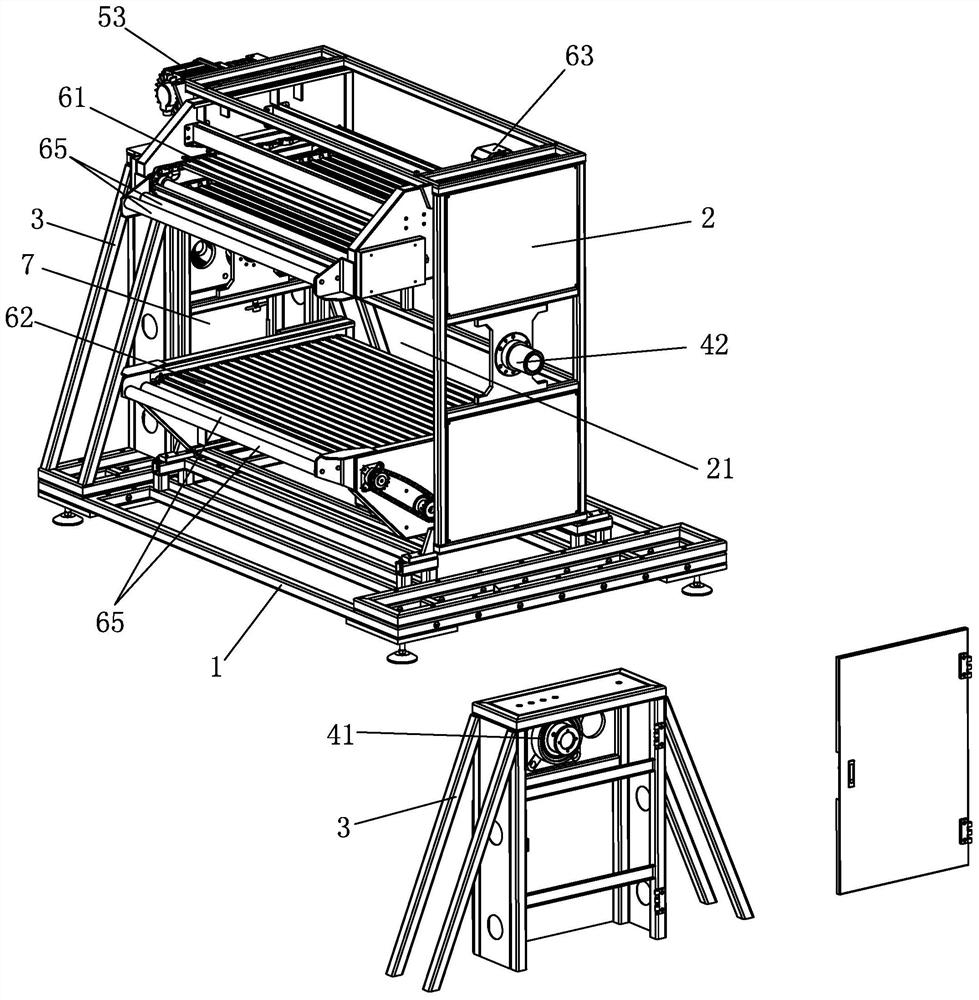

[0026] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

[0027] Such as Figure 1-4 As shown, a tobacco leaf box turnover control method, the steps are as follows:

[0028] a. The upper side motor 63 arranged on the turning seat 2 rotates in the forward direction, and the lower side motor 64 rotates in the reverse direction, respectively driving the upper side conveyor chain plate 61 to rotate in the forward direction and the lower side conveyor chain plate 62 to rotate in the reverse direction. The conveying chain plate 61 and the lower conveying chain plate 62 are respectively arranged on the upper side of the accommodating cavity 21 and the upper side of the accommodating cavity 21, and the width between the side conveying chain plate 61 and the lower side conveying chain plate 62 is 300mm of the tobacco leaf box body. height, smoothly and quickly send the tobacco leaf box into the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com