Low-power dual-locking lifting track system and method

A double-locking, lifting track technology, applied in lifts, elevators in buildings, transportation and packaging, etc., can solve the problems of cumbersome operation, heavy workload, and complicated track system, and achieve low energy consumption, low cost, and high efficiency. The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

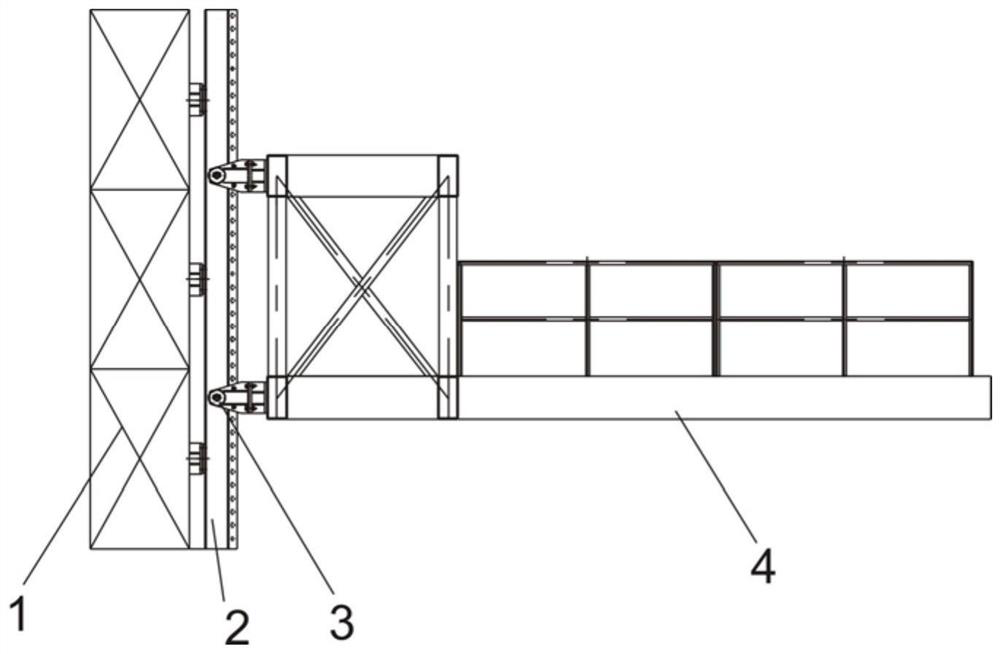

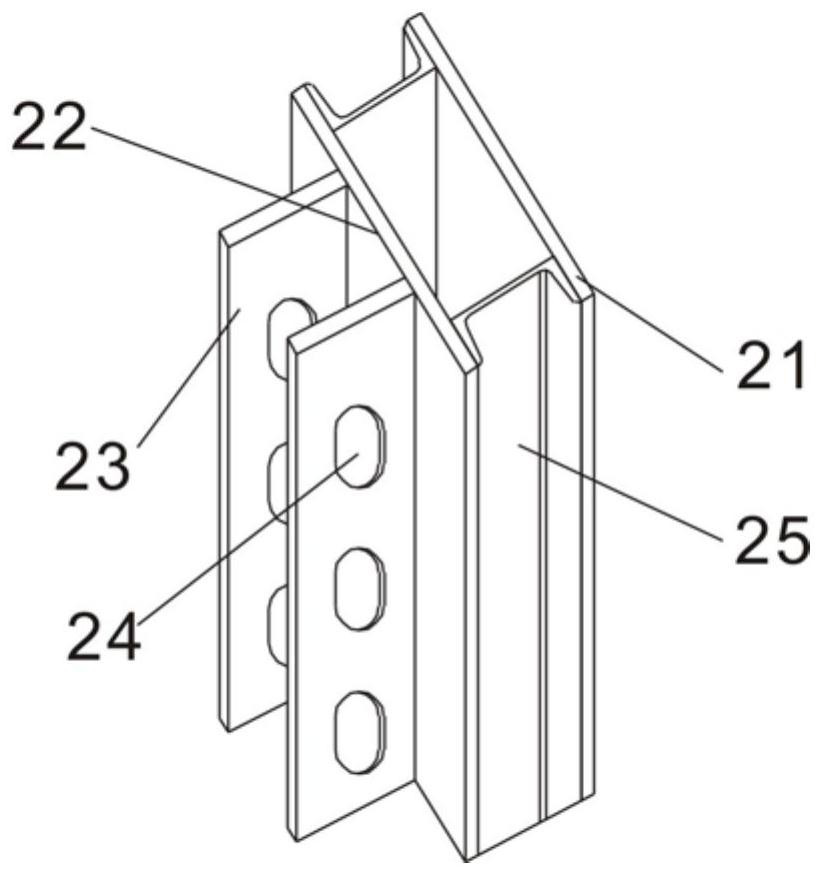

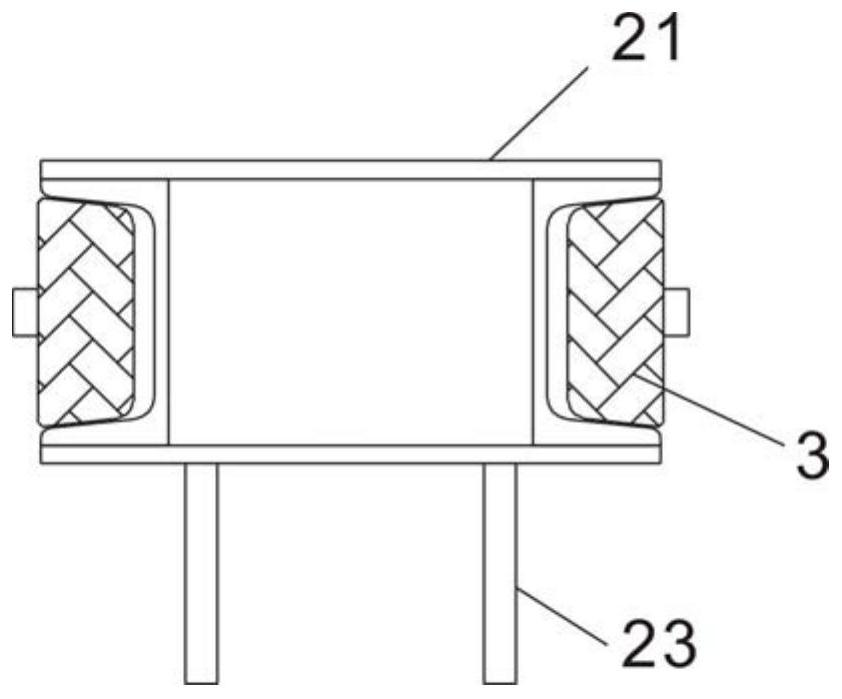

[0040] see Figure 5 As shown, a low-power double-lock lifting track system includes a low-power double-lock mechanism, and the low-power double-lock mechanism includes a motor device, an trapezoidal screw 106, a screw nut 107 and a lever 109.

[0041] The motor device is fixed on the support 101, and the support 101 can be made of steel plate. The motor 102 device includes a motor 102, a reducer 103 and a shaft coupling 104, and the tail end of the motor 102 has a brake. The motor 102, the reducer 103 and the coupling 104 are connected in sequence. The motor unit is used to provide power.

[0042] The trapezoidal screw 106 is fixedly connected with the motor device, specifically, coaxially fixedly connected with the shaft coupling 104 . The lead screw 106 rotates under the power provided by the motor 102 .

[0043] Lead screw nut 107, it has two, and their thread direction is installed on the lead screw 106 oppositely, under the rotation of lead screw 106, two lead nuts 1...

Embodiment 2

[0051] see Figure 6 As shown, a low-power double-locking lifting track system of this embodiment includes the low-power double-locking lifting track system of Embodiment 1; The upper friction plate 111 is clamped and locked or released.

[0052] Wherein, the extended track 112 can be set on one side of the lifting track mechanism, or can be set on both sides of the lifting track mechanism at the same time.

[0053] The Track 112 is a completely new track design. Compared with the current track system, the vertical plate of the current track system is canceled, and a section of the steel plate of the profile channel steel is elongated, and the elongated part is the track 112 . The rail 112 cooperates with the friction plate 111 for braking.

[0054] Among them, multiple low-power double locking mechanisms can be arranged along the length direction of the track 112 and used simultaneously to increase locking force and safety factor.

[0055] The present invention changes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com