Mounting structure of planet roller and lifting appliance

A technology for installing structures and rolls, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of increasing the production cost of copper pipes, difficulties, and the value of rolls cannot be fully utilized, so as to save procurement and production costs and simplify installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

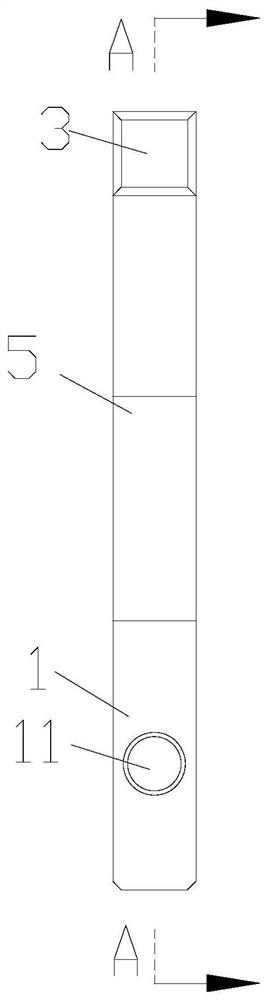

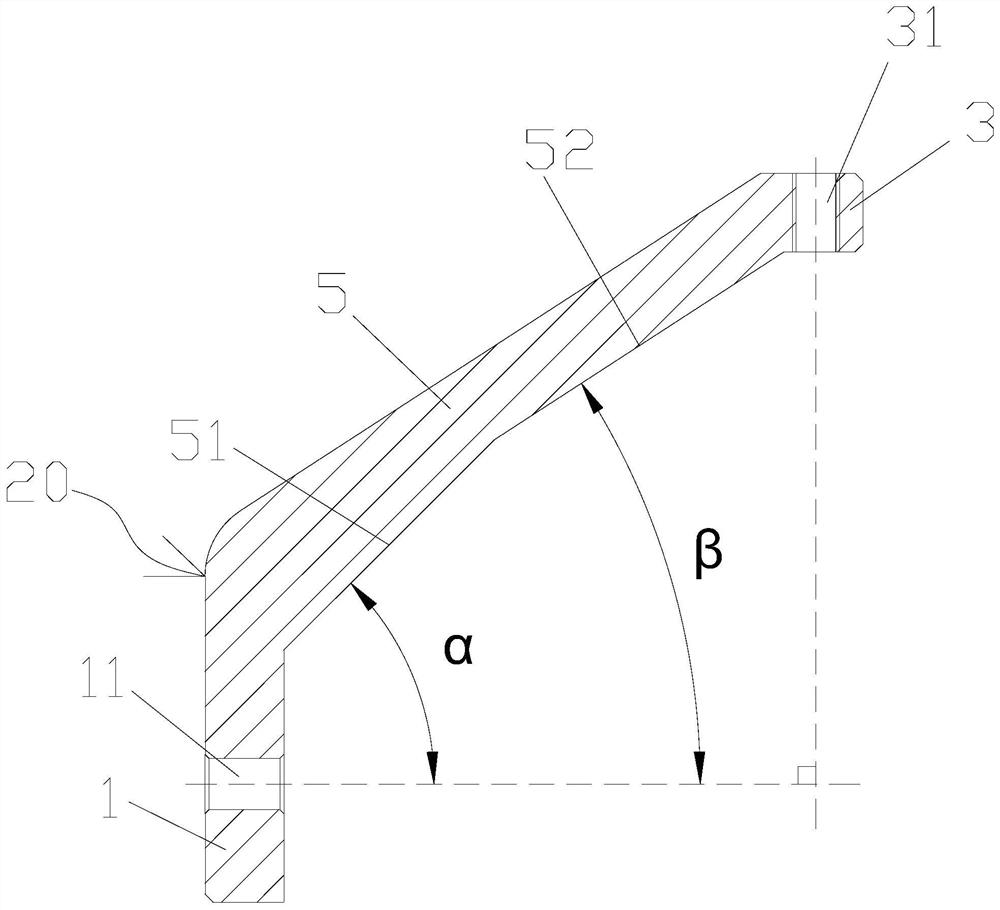

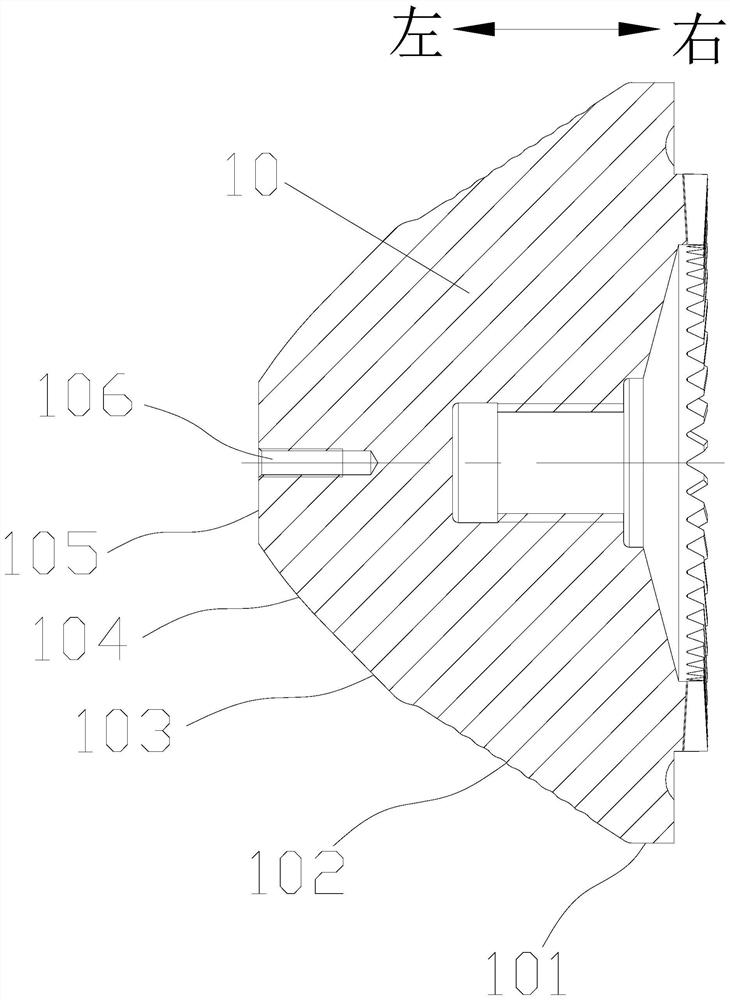

[0032] Such as Figure 1 to Figure 4 As shown, this embodiment provides an installation structure of a planetary roll and a hanger, including a planetary roll 10 and a hanger 20 installed on the planetary roll, the planetary roll 10 is provided with a cylindrical area 101, a bite Entry area 102, diameter reduction and wall reduction area 103, dynamic leveling area 104, and return to circle sizing area 105, on the end face of return to circle sizing area 105, a connection area 106 for connecting with the sling 20 is provided, the sling 20 includes a roll connection part 1, a suspension ring connection part 3 and a connection transition part 5. The roll connection part 1 is provided with a first installation part 11 on the roll connection part 1, and the first installation part 11 is set corresponding to the connection area 106. Through the first The installation part 11 is connected with the connection area 106 to realize the installation of the roll connection part 1 and the p...

Embodiment 2

[0041] Such as Figure 5 to Figure 8 As shown, this embodiment is based on the first embodiment, and the structure of the roll connection part 1 is modified, so that the hanger in this embodiment can be applied to the new type of end-face convex ring block type planetary roll 10, in this embodiment In the embodiment, the cross-sectional shape of the roll connection part 1 is a circle. Since the return-to-circle sizing zone 101 of the end-face convex ring block type planetary roll 10 is provided with an escape hole 1051 corresponding to the connection zone, the circular design Make the contact area between the roll connection part and the end face convex ring block type planetary roll 10 larger, and make the installation of the spreader and the end face convex ring block type planetary roll 10 more stable; the first installation part 11 is a penetrating roll connection part 1 The connecting area 106 of the planetary roll 10 is a screw hole, and the connecting piece 2 is a bolt....

Embodiment 3

[0043] A kind of using method of sling, realizes based on the structure of the sling of embodiment one or embodiment 2, comprises the following steps:

[0044] S1: abut the mounting and positioning surface 51 of the spreader against the contour of the diameter-reducing and wall-reducing area of the planetary roll 10;

[0045] S2: Make the center of the first installation part 11 of the roll connection part 1 correspond to the center of the connection area 106 of the planetary roll 10;

[0046] S3: Thread the connector 2 through the first installation part 11 and screw it to the connection area 106;

[0047] S4: Screw the lifting ring 4 onto the second installation part 31 of the connecting part 3 of the lifting ring;

[0048] S5: pass the sling through the suspension ring 4;

[0049] S6: The hoisting device lifts the planetary roller 10 by retracting the sling, so that the assembly surface of the planetary roller 10 is installed in a vertical state.

[0050] Through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com