Overweight assembly type prefabricated stair hoisting device and construction method

A hoisting device and construction method technology, which is applied in the direction of hoisting equipment braking devices, winch devices, cranes, etc., can solve the problems of self-heavy prefabricated stairs and difficulty in hoisting construction operations, etc., and achieve high construction efficiency and fast installation speed , The effect of small construction impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

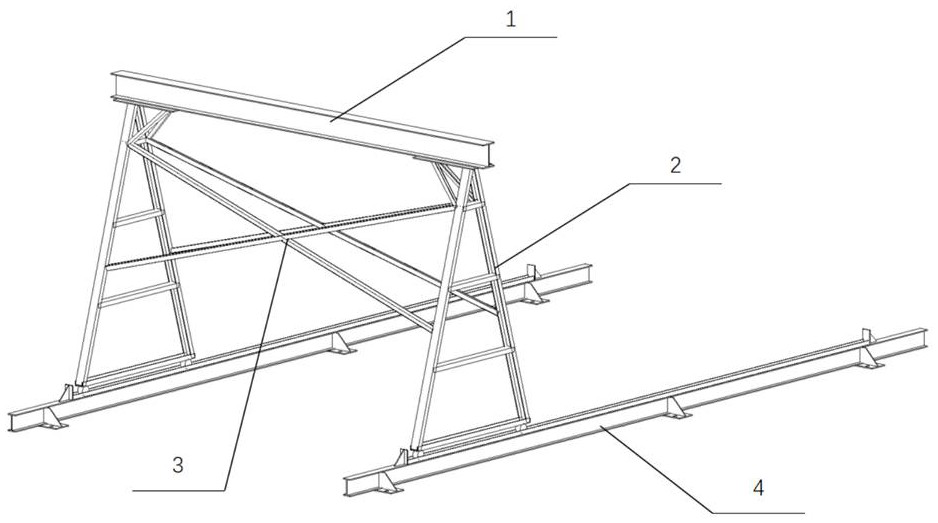

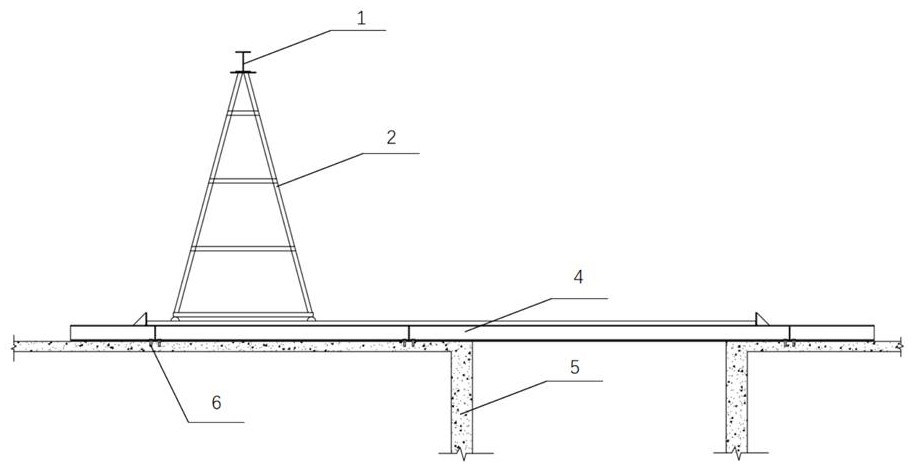

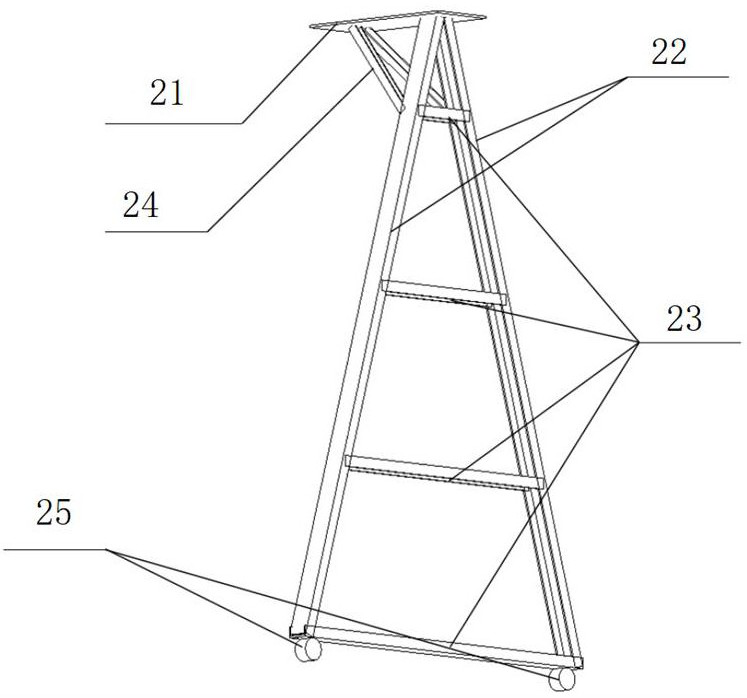

[0042] Such as Figure 1-5 As shown, the super-heavy assembled prefabricated staircase hoisting device according to the preferred embodiment of the present invention includes a prefabricated staircase installation structure and a lifting mechanism, wherein the prefabricated staircase installation structure includes: truss structure rail 4 and truss structure. The two truss structure rails 4 are arranged in parallel, and the bottom of the truss structure rail 4 is provided with a plurality of structural connection positions at intervals. The truss structure includes a truss structure main girder 1 and a vertical support frame 2 , and the two vertical support frames 2 are symmetrically arranged in two truss structure rails 4 and are slidably connected with the truss structure rails 4 . The main beam 1 of the truss structure is arranged on the top of the vertical support frame 2, and the two ends of the main beam 1 of the truss structure are respectively fixedly connected with th...

Embodiment 2

[0049] In another preferred embodiment, as Figure 9 As shown, the prefabricated staircase installation structure also includes a round steel snap ring 9, which is used to fix the truss structure and the truss structure track to prevent the fixed pulley from jumping out of the truss structure track 4 due to excessive acceleration during the prefabricated staircase hoisting process.

[0050] In this embodiment, the specification of the horizontal supporting steel plate 21 is 800mm×300mm, and the thickness is 10mm.

[0051] The specification of the lateral reinforced square steel 3 is 40mm×40mm×3mm. The track back plate 45 is a steel plate with a specification of 200mm×500mm×10mm, and the anti-overturn slope plate 46 is a trapezoidal steel plate with a thickness of 10mm. The vertical limit baffle 42 is a steel plate with a specification of 150mm×100mm×10mm, and the diagonal brace 41 of the triangular baffle is a right-angled triangle steel plate with a thickness of 10mm.

Embodiment 3

[0053] Such as Figure 6 As shown, the present invention also provides a prefabricated staircase hoisting construction method using the above-mentioned overweight assembled prefabricated staircase hoisting device, comprising the following steps:

[0054] Step S1. According to the actual situation of the project construction, combined with the site construction conditions, use BIM software to carry out the detailed design of the prefabricated staircase split, and select the installation structure and lifting mechanism of the prefabricated staircase according to the self-weight, length dimension and stairwell size of the prefabricated staircase after the split ;

[0055] Step S2. Simulating the construction process, including simulating the whole process of lifting the prefabricated stairs to the structural roof by the tower crane, and transferring the prefabricated stairs by the truck, and accurately positioning the positions of the truss structure and the truss structure track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com