Device and method for devolatilizing polymer solution

A polymer solution and flange technology, which is applied in the field of polymer solution devolatilization devices, can solve the problems of not giving the polymer solution devolatilization efficiency and the temperature of the polymer solution, etc., to achieve high operating flexibility and reduce resistance consumption. , the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

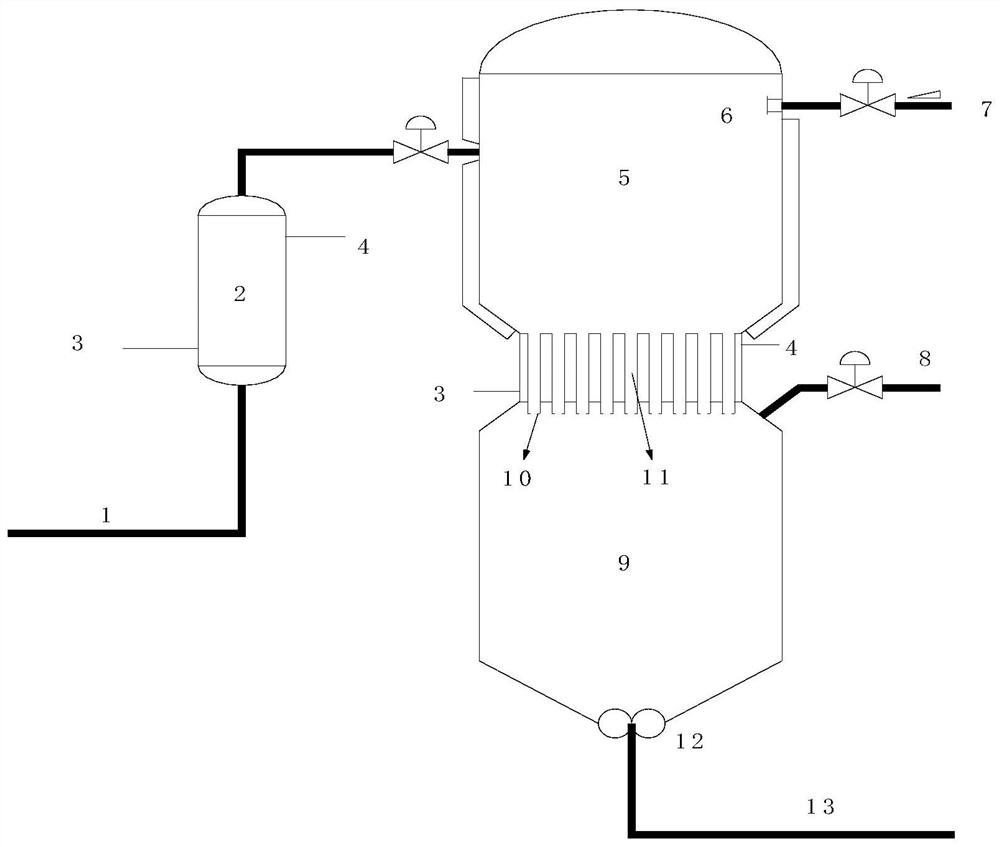

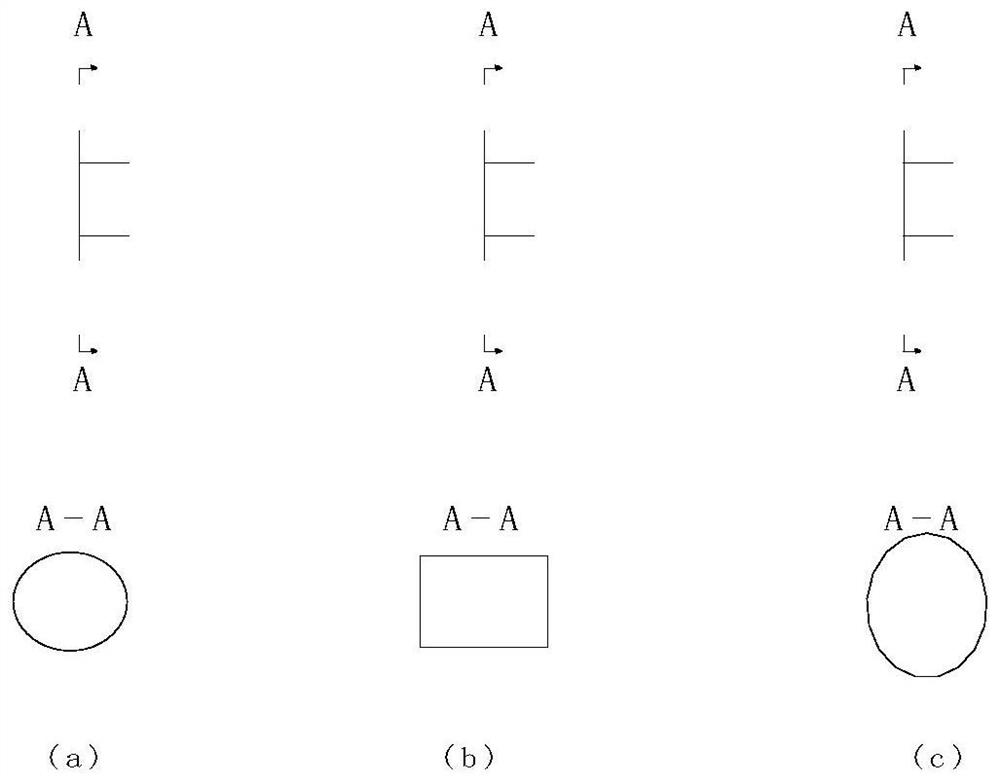

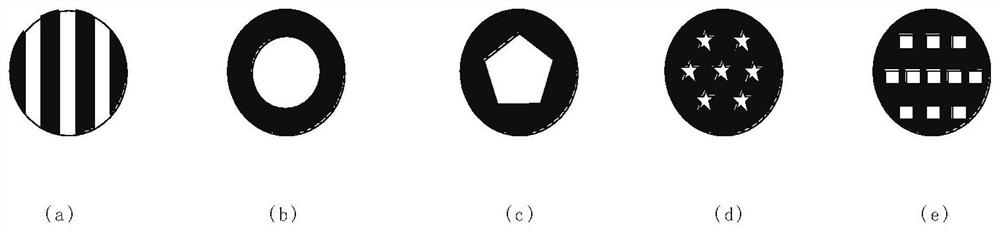

[0055] The devolatilization device of this embodiment is as follows figure 1 shown, where the baffle adopts figure 2 The circular baffle in c, the gas phase flows into the gas phase outlet of the flash tank through the wall gap between the baffle and the flash tank, the flow area is 1.5 times the cross-sectional area of the gas phase outlet, and the slope of the gas phase outlet pipeline of the flash tank is 3゜ , the connection between the heater and the flash tank and the evaporation tank is flange connection. The heating medium in the heater is heat-conducting oil, the diameter of the heat exchange tube of the heater is Φ19×2mm, and the inner diameter is 15mm. Adoption of throttling facilities image 3 Strip holes are shown in a.

[0056] according to figure 1 As shown in the process, containing 15% wt ethylene-octene copolymer polymer solution, the solvent is cyclohexane, and it enters the preheater through the polymer solution feed line, preheats to 230 °C, and decom...

Embodiment 2

[0058] Using the same devolatilization device and process as in Example 1, the settings of the baffle, the heater and the gas phase pipeline of the flash tank remain unchanged, and the throttling facility adopts image 3 Rectangular hole shown in e.

[0059] The polymer solution containing 70wt% polysulfone, the solvent is chlorobenzene, enters the preheater through the polymer solution feed line, preheats to 220 ° C, and enters the flash tank for flash evaporation after decompression by the regulating valve, and the flash tank operation The temperature is 189.5 °C, the operating pressure is 1BarA, and the polymer solution with a polysulfone content of 90.7% is obtained at the bottom of the flash tank after flashing. After being heated to 194 °C by the heater at the bottom of the flash tank, it enters the evaporation tank. The operating temperature of the evaporation tank is 176.7 °C , the operating pressure is 5mBar, and the polymer melt with volatile content less than 500ppm...

Embodiment 3

[0061] The same devolatilization device and process are used as in Example 1, the only difference is the use of figure 2 The rectangular gas-phase baffle shown in b, the gas-phase flow area between the baffle and the wall of the flash tank is 1.2 times the cross-sectional area of the gas-phase outlet.

[0062] A polymer solution containing 50 wt % styrene-acrylonitrile (SAN) polymer, the remainder of the solution consisting of 20 wt % ethylbenzene, 22.5 wt % styrene and 7.5 wt % acrylonitrile, via the polymer solution feed line Enter the preheater, preheat to 230°C, and then enter the flash tank for flash evaporation after decompression by the regulating valve. The operating temperature of the flash tank is 185.6°C, and the operating pressure is 2BarA. After flashing, the SAN content at the bottom of the flash tank is 77.9%. The polymer solution is heated to 190 ℃ by the heater at the bottom of the flash tank and then enters the evaporating tank. The operating temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com