Tooth-profile-variable grinding disc for cylindrical pulping machine

A cylindrical refiner technology, applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problem of little or no change in tooth shape of grinding teeth, small adjustment range of refining quality, Restricting the effect of refining and other issues, to achieve the effect of facilitating adjustment, improving the function of grinding and refining, and improving the quality of pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

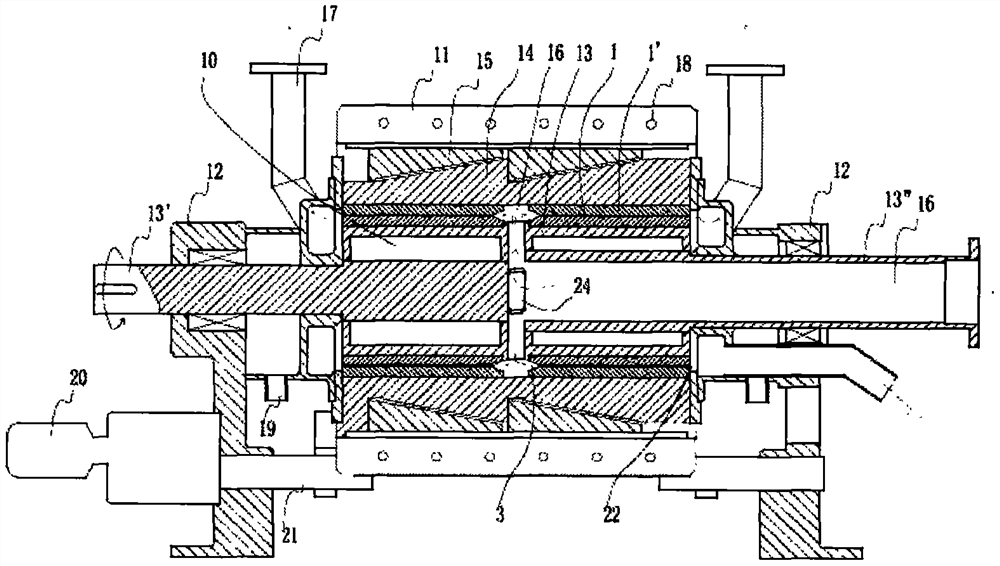

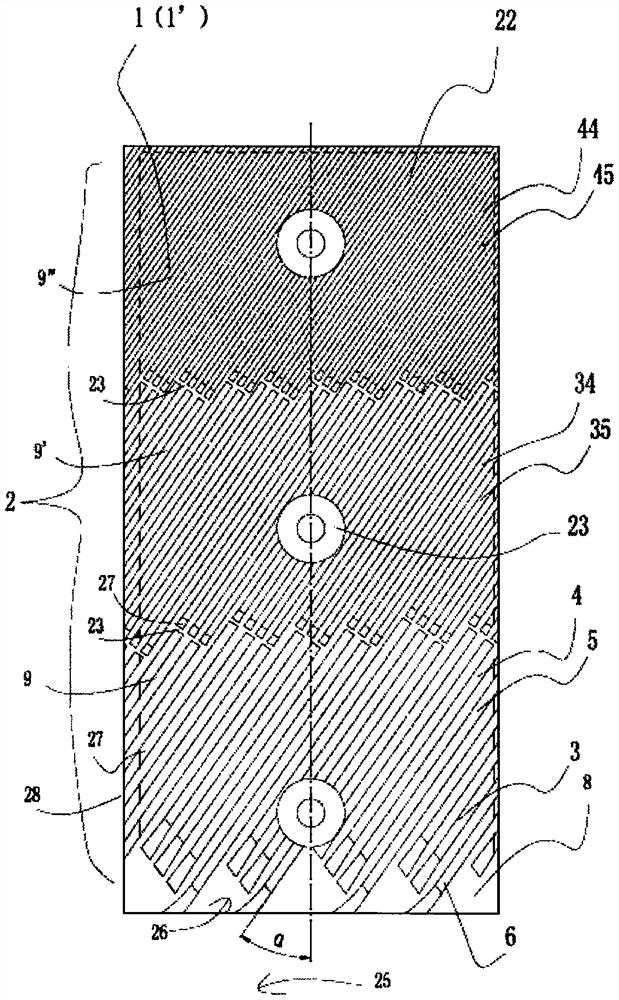

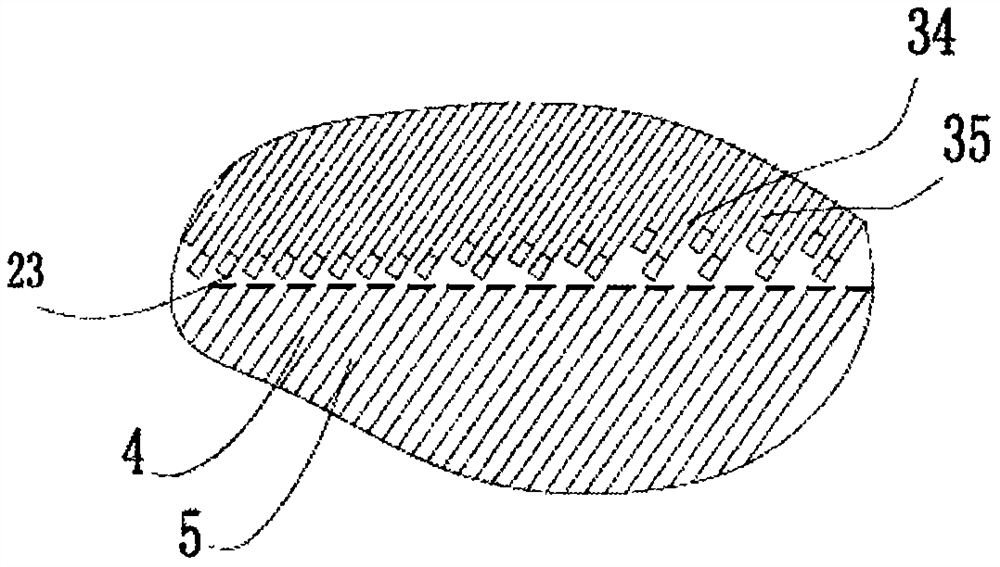

[0025] figure 1 A cylindrical refiner 10 structure is shown. The structure of the cylindrical refiner 10 includes a body casing 11, a frame 12, a rotor 13, a slide plate 14, a pulp inlet channel 16, and a pulp outlet channel 17, etc. The rotor 13 and the slide plate 14 are used together. The rotor 13 is supported and fixed by the frame 12 and bearings at both ends. One end 13' is powered by an external power source to make it rotate, and the other end 13" has a hollow structure inside as a passage 16 for pulp raw materials. The pulp raw materials are transported by pipelines and then enter the rotor. 13 The hollow channel 16 overflows radially from several overflow holes 24 provided at about the middle of the rotor 13, and enters the gap between two pairs of four groups of grinding discs 1, 1' installed on the left and right sides of the overflow hole 24 along the axial direction. Among them, the two pairs of four groups of grinding discs 1, 1' are composed of rotor grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com