Precast tubular pile static pressure construction device integrating positioning and pile sealing and method

A technology of prefabricated pipe piles and construction devices, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., to improve the overall bearing capacity, avoid rebound phenomenon, and ensure firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

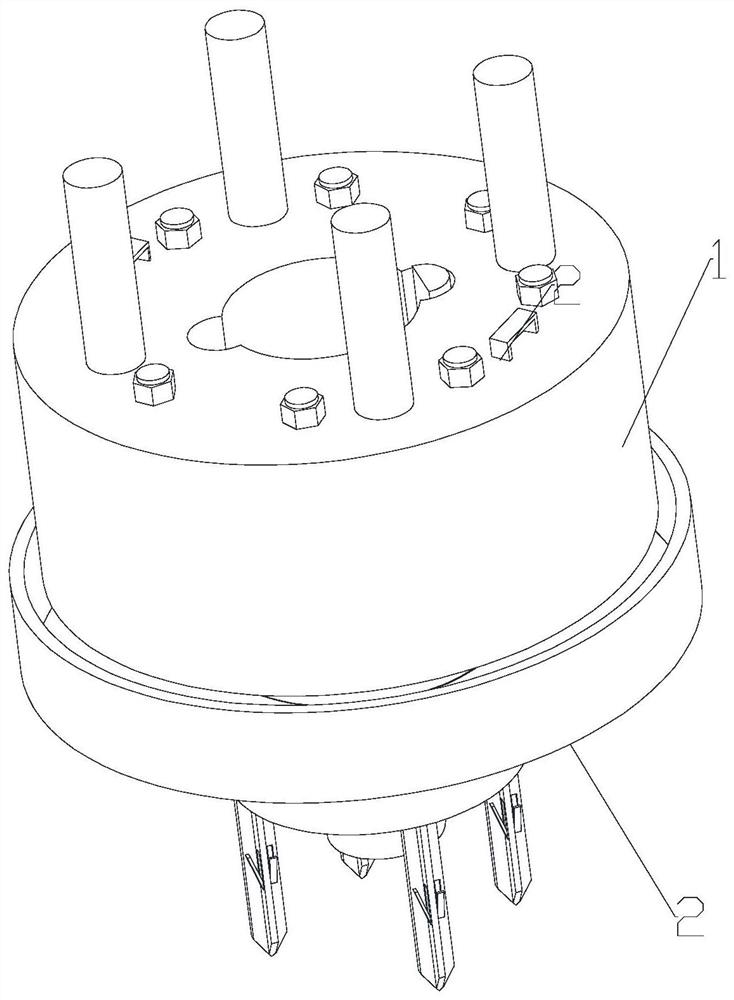

[0043] Please refer to Figure 1-11 , a prefabricated tubular pile static pressure construction device integrating positioning and sealing piles in this embodiment, such as figure 1 As shown, it includes a pressure distribution body 1 and a pressure-bearing fixed base 2 that are arranged to match each other up and down;

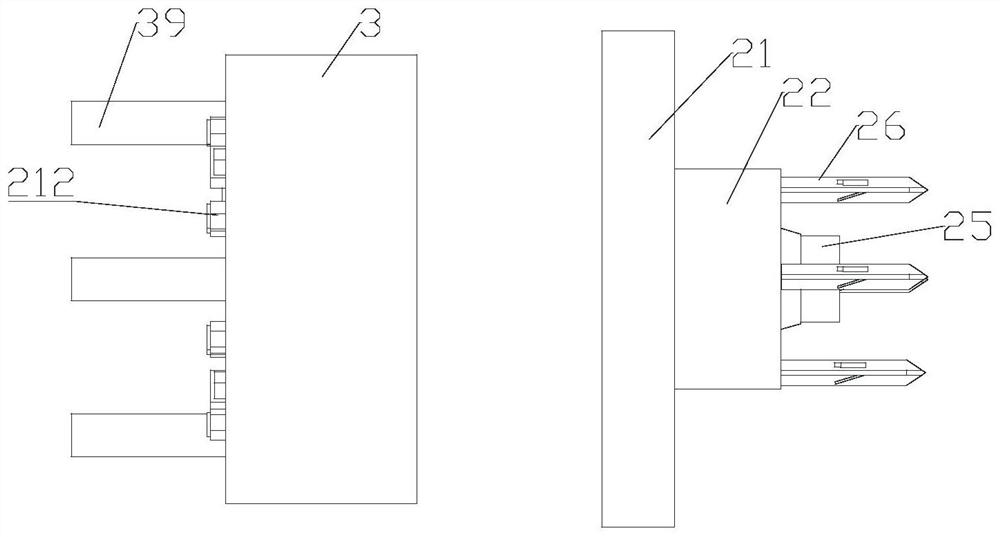

[0044] like figure 2 , Figure 10 and Figure 11As shown, the pressure distribution body 1 includes an annular pressure distribution block 3, the middle part of the pressure distribution block 3 is provided with a pipe pile through hole 31, and the inner side of the pipe pile through hole 31 is symmetrically provided with a first arc-shaped groove. 32. The second arc-shaped groove 33, one end of the first arc-shaped groove 33 is hinged with an arc-shaped downward pressure beam 34, and the horizontal side of the arc-shaped downward pressure beam 34 is provided with a pressure device groove 35, the One end of the slot 35 of the pressurizing device is hinge...

Embodiment 2

[0056] This embodiment provides a method for construction using the prefabricated pipe pile static pressure construction device as described in Embodiment 1, including the following steps:

[0057] Step 1: Drill the pre-buried hole at the predetermined piling position, install the prefabricated pipe pile static pressure construction device on the static press, pressurize the pre-buried hole vertically, until the disc-shaped pressure-bearing platform 21 is parallel to the ground, and A total station is used to ensure that the prefabricated pipe pile static pressure construction device is installed vertically;

[0058] Step 2: Lift the prefabricated pipe pile, align it with the set pipe pile through hole 31, and pass through the feeding through hole 23 and the positioning pipe 25 in sequence, and at the same time move the static pressure pile machine until the pressurized pile head is facing the prefabricated pipe pile Top, connecting the prefabricated pipe pile and the pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com