Blank drying equipment for artificially synthesizing mullite by dry method and using method of blank drying equipment

A technology of artificial synthesis and drying equipment, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problem of uneven drying of drying equipment, reduce the production efficiency of mullite, increase the workload of staff, etc. problem, achieve the effect of solving uneven drying, compact structure and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

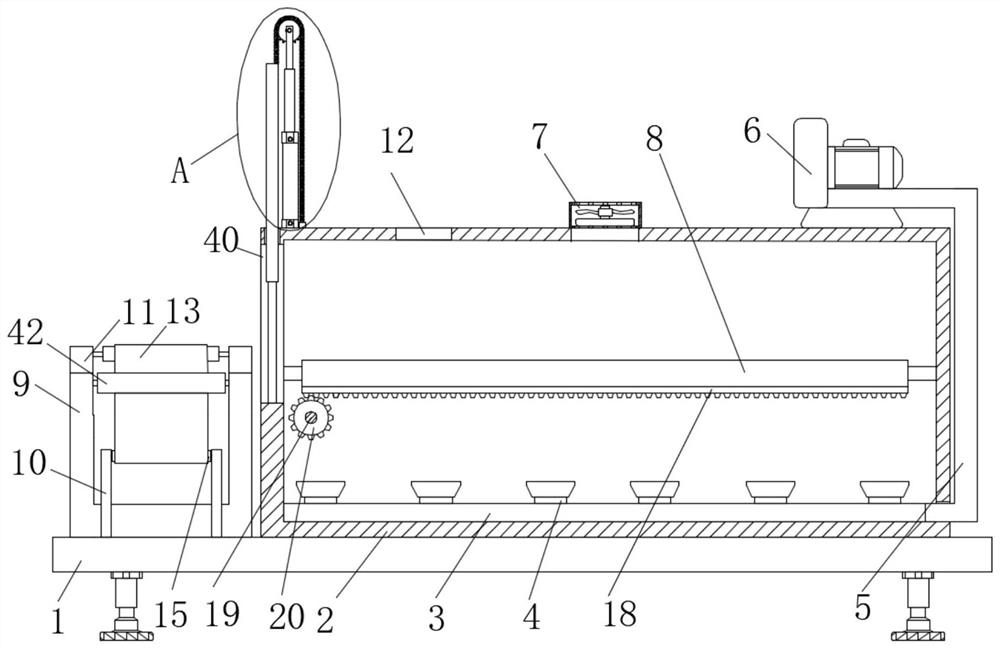

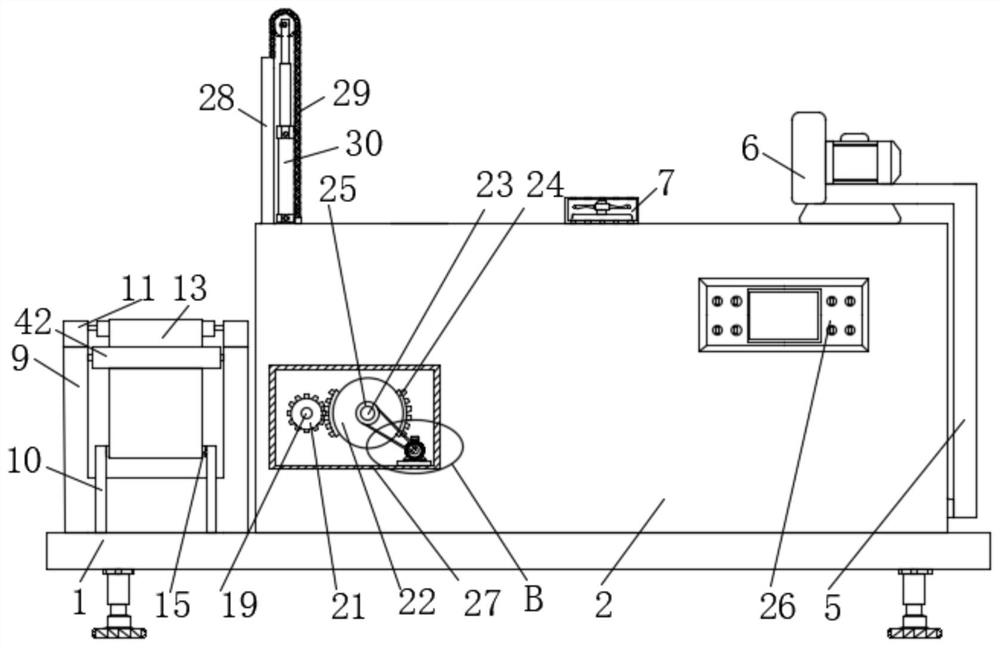

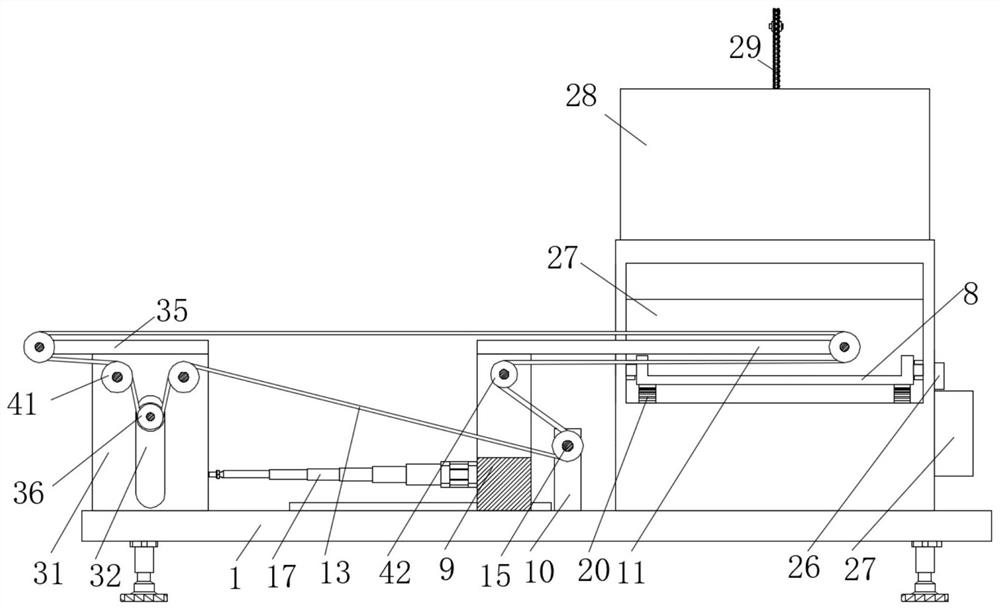

[0039] Such as Figure 1-7 As shown, a billet drying equipment for artificially synthesizing mullite by dry method includes a base 1, a drying box 2 is fixedly installed on the top of the base 1, and the same drying plate is slidably connected to the inner walls of both sides of the drying box 2 8. The drying box 2 is provided with a transmission assembly that drives the drying plate 8 to slide. One side of the drying box 2 is provided with a pick-and-place opening 40, and the inner walls of both sides of the pick-and-place mouth 40 are slidably connected to the same sealing plate 28. The dry box 2 is provided with a lifting assembly for lifting the sealing plate 28. A hot air blower 6 is fixedly installed on the top of the drying box 2. The hot air delivery port of the hot air blower 6 is fixedly connected with a hot air delivery pipe 5, and one end of the hot air delivery pipe 5 runs through The inner wall of one side of the drying box 2 extends into the drying box 2 , one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com