Conical plug gauge painting thickness inspection gauge block and inspection method

An inspection method and technology of tapered plugs, applied in the direction of mechanical thickness measurement, measuring devices, mechanical measuring devices, etc., can solve the problems of affecting the detection accuracy, low efficiency, easy to fall to one side, etc., and achieve high detection accuracy and numerical value high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

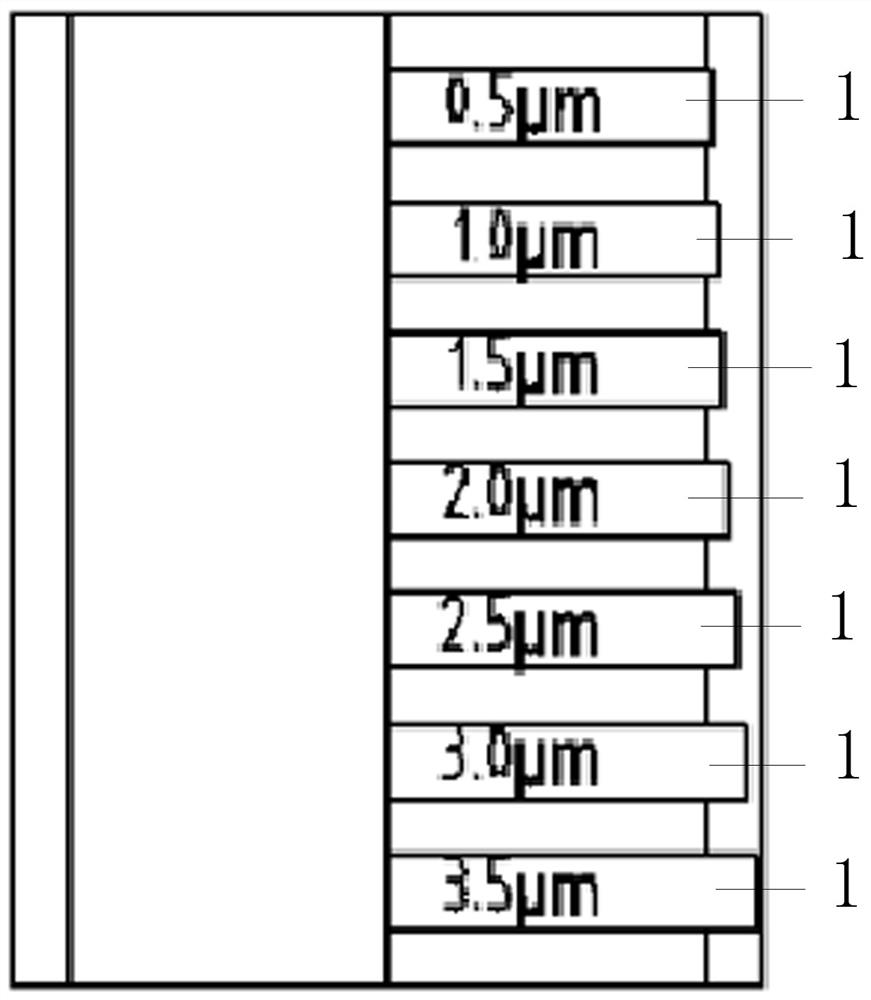

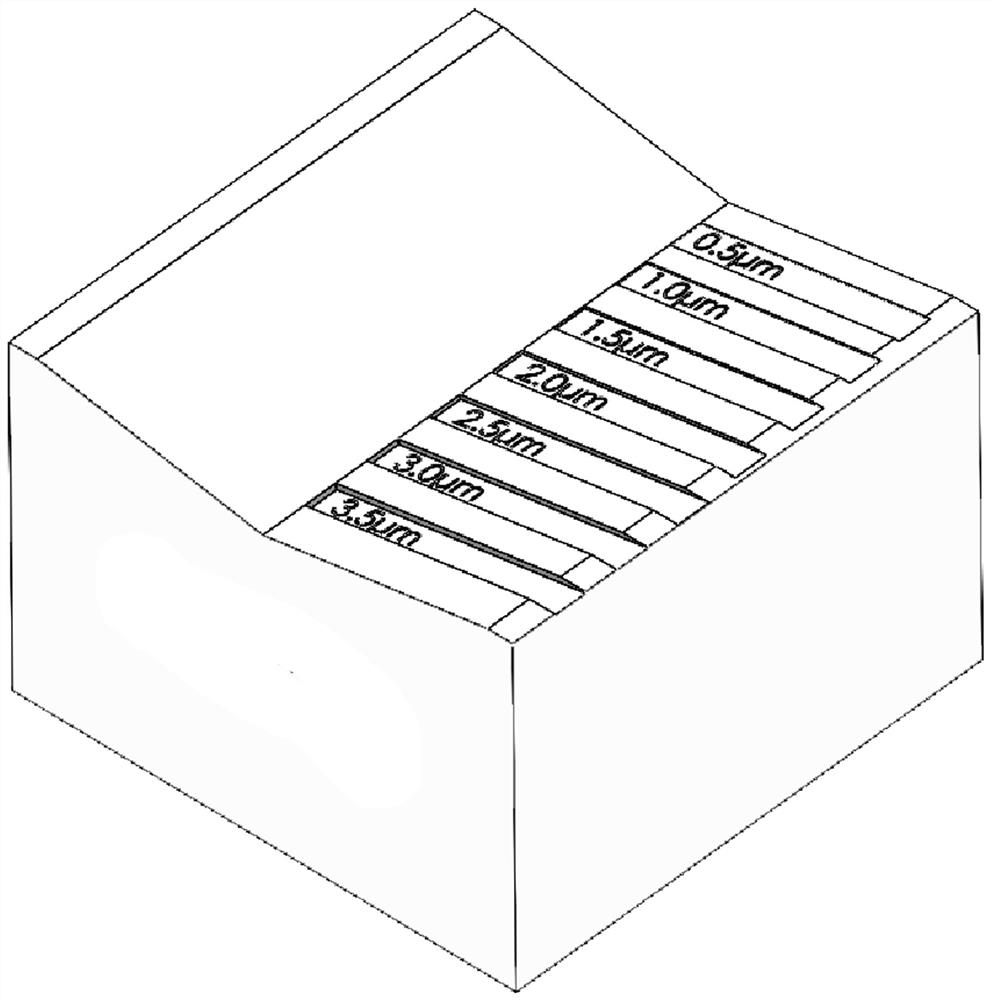

[0028] A tapered plug gauge coloring thickness inspection gauge block, comprising a cube; one surface of the cube has a V-shaped surface structure, and a plurality of inspection grooves parallel to each other are processed on one side of the V-shaped surface; the inspection grooves are perpendicular to the middle line of the V-shaped surface (see figure 2 As shown, it is parallel to the movement direction during measurement to ensure the accuracy of the results), and the distance between adjacent inspection grooves is equal; the inspection groove runs through the surface to ensure that the contact line between the gauge block and the plug gauge (that is, the colored line) can pass through All inspection grooves ensure more accurate inspection results; the depth of inspection grooves increases or decreases in turn. The inspection grooves are marked with their respective depth numbers and unit symbols. The number and depth distribution of inspection grooves can be set accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com