Harmonic reducer comprehensive performance test equipment input fixing structure

A harmonic reducer and test equipment technology, applied in the field of precision instruments and mechanical transmission, can solve the problems of non-uniformity of fixed ends and poor fixing effect, so as to improve correctness and accuracy, facilitate installation and disassembly, and have good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

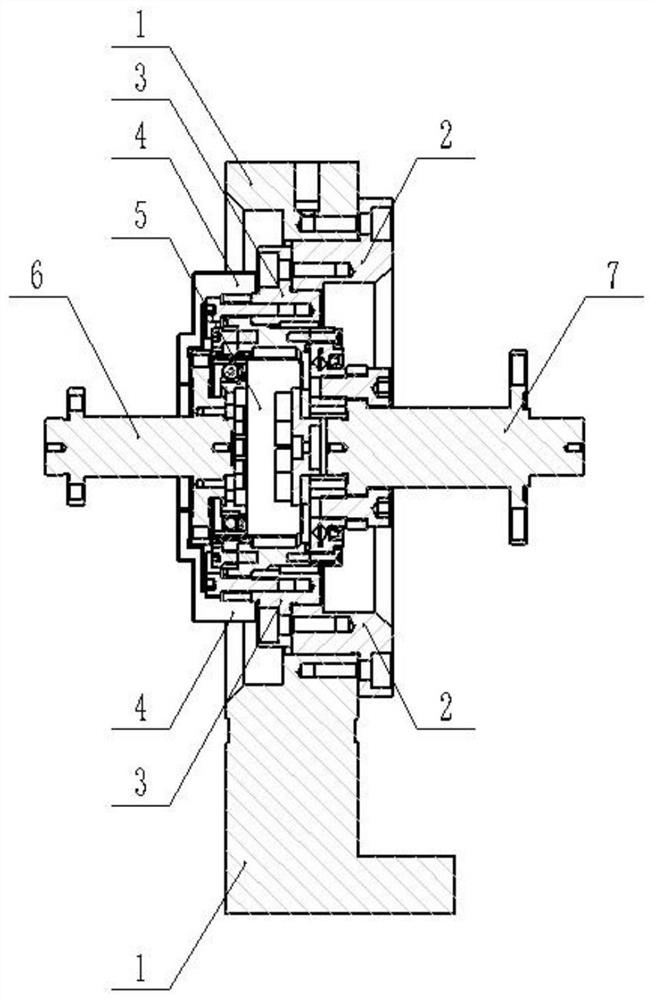

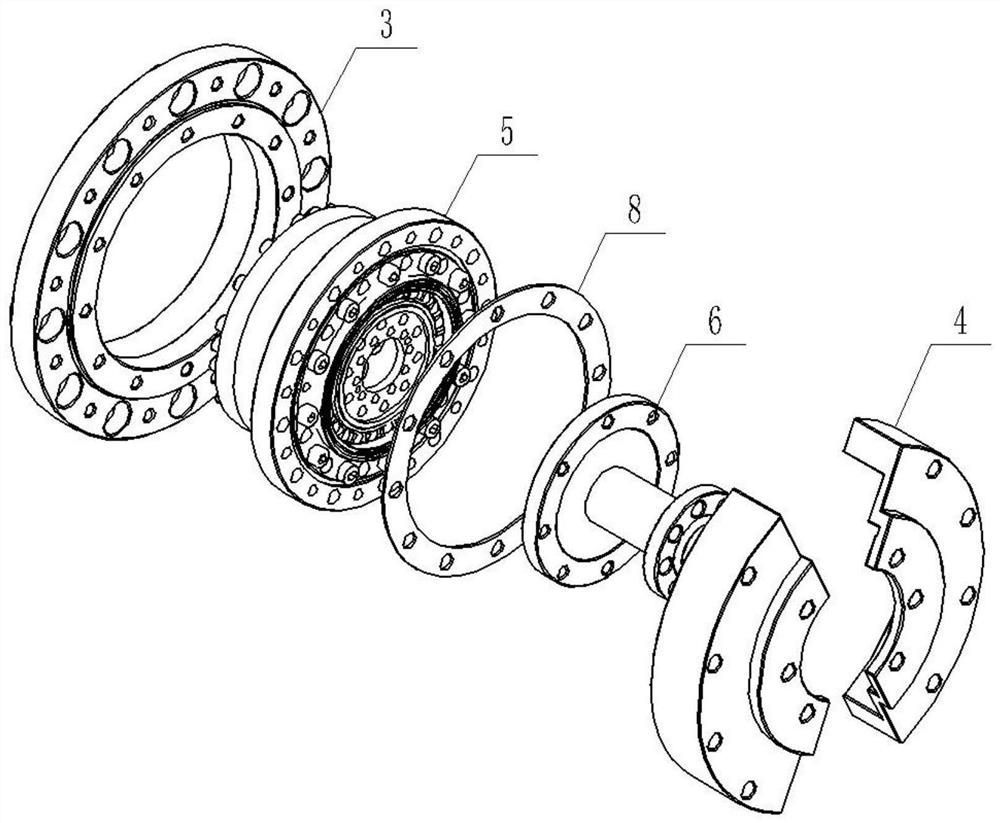

[0018] The technical solution adopted by the present invention is a structure for inputting and fixing the comprehensive performance test equipment of the harmonic reducer. Disc 4, reducer input shaft 6 and reducer output shaft 7.

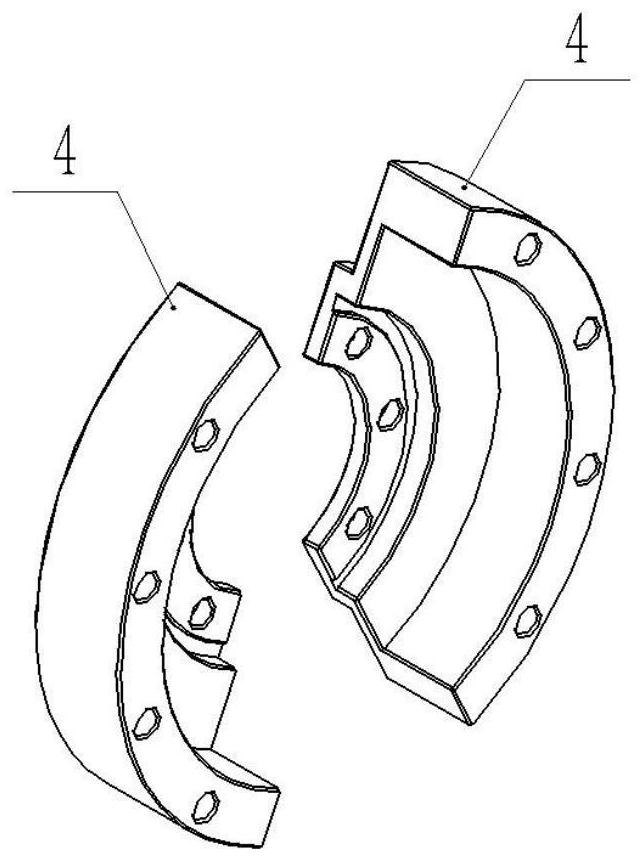

[0019] The positioning plate 2 is installed on the reducer mounting bracket 1 through a set of screws, and the connecting positioning sleeve 3 is installed on the positioning plate 2 from the input side. The connecting positioning sleeve 3 has two sets of mounting holes for the inner ring and the outer ring. The wave reducer 5 is installed on the connecting positioning sleeve 3 through the inner ring mounting hole, the reducer input shaft 6 and the reducer output shaft 7 are respectively installed on the input end and output end of the measured harmonic reducer 5 through the flange end face, and the input The fixed disc 4 has two sets of mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com