Raw material extraction and concentration all-in-one machine for cosmetic production and operation method thereof

A technology of cosmetics and all-in-one machine, which is applied in the direction of chemical instruments and methods, separation methods, evaporator accessories, etc. It can solve the problems that the raw materials cannot be fully stirred, the extraction and concentration cannot be carried out at the same time, and the purity of the extract is not high, so as to improve the extraction. Effects on efficiency and extraction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

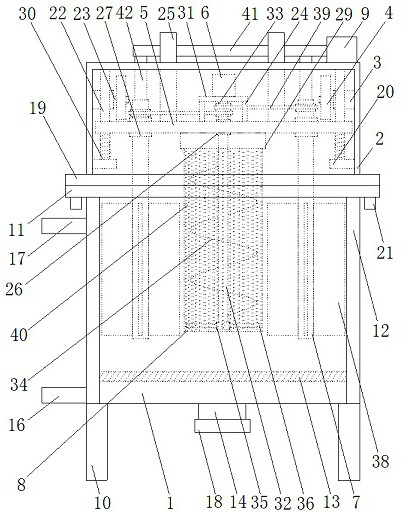

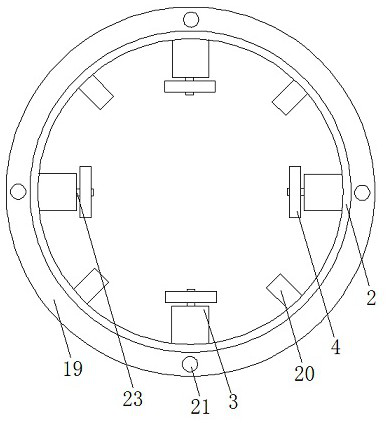

[0034] as attached Figure 1-7 As shown, an all-in-one machine for extracting and concentrating raw materials for cosmetic production includes a cylinder body 1, a cover body 2, a motor one 3, a cam 4, an adjustment plate 5, a motor two 6, a driven shaft 7, a material barrel 8 and a steam pump 9 , the cylinder body 1 is arranged on the bracket 10, and a discharge pipe 14 is arranged at the bottom of the cylinder body 1, and the cylinder body 1 and the bracket 10 are connected by welding to improve the connection between the cylinder body 1 and the bracket 10 Strength, enhance the structural strength of the cylinder 1, the cover 2 is flexibly connected with the cylinder 1, a positioning block 20 is arranged on the inner wall of the cover 2, and a column is arranged between the top of the cover 2 and the positioning block 20 22. The motor one 3 is arranged on the inner wall of the cover body 2, and a transmission shaft one 23 is arranged on the motor one 3, and the cam 4 is inst...

Embodiment 2

[0051] as attached Figure 8-9 As shown, an all-in-one machine for extracting and concentrating raw materials for cosmetic production includes a cylinder body 1, a cover body 2, a motor one 3, a cam 4, an adjustment plate 5, a motor two 6, a driven shaft 7, a material barrel 8 and a steam pump 9 , the cylinder body 1 is arranged on the bracket 10, and a discharge pipe 14 is arranged at the bottom of the cylinder body 1, and the cylinder body 1 and the bracket 10 are connected by welding to improve the connection between the cylinder body 1 and the bracket 10 Strength, enhance the structural strength of the cylinder 1, the cover 2 is flexibly connected with the cylinder 1, a positioning block 20 is arranged on the inner wall of the cover 2, and a column is arranged between the top of the cover 2 and the positioning block 20 22. The motor one 3 is arranged on the inner wall of the cover body 2, and a transmission shaft one 23 is arranged on the motor one 3, and the cam 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com