Rotation speed steady-state value fitting method and device for ball-wire mill

A wire rod rolling mill, bar and wire rod technology, which is applied in the field of fitting of the steady state value of the rod and wire rod rolling mill rotation speed, can solve the problems of large deviation of the actual rotation speed of the rod and wire rolling mill, large deviation of the rotary speed of the rod and wire rolling mill, and large deviation of the rod and wire rolling mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

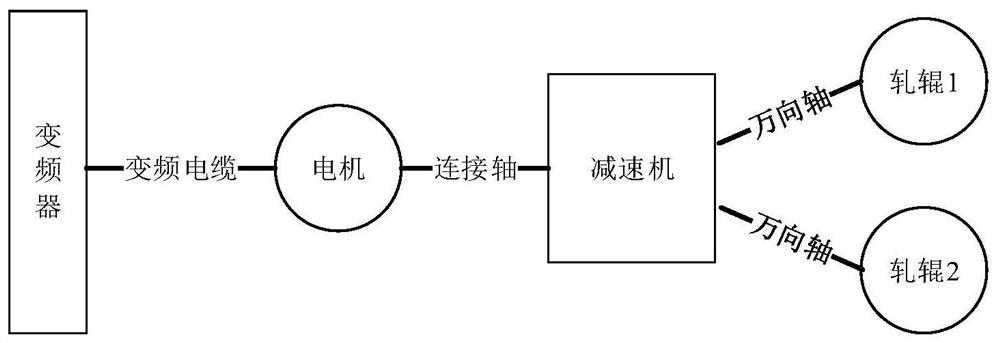

[0033] Usually, multiple rolling mills are set up on the hot continuous rolling production line of rods and wires, and each rolling mill works according to a given speed and torque. The rotation speed of each rolling mill in the hot continuous rolling production line is different. From the first rolling mill to the last rolling mill, the rotating speed is getting higher and higher, so that there will be no accumulation in the process of moving the billet from the first rolling mill to the last rolling mill , affecting the work of the entire production line.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com