Small component gripping and mounting manipulator

A technology of manipulators and small parts, applied in the field of manipulators, can solve the problems of high cost, weak gripping, and insufficient functions of grippers, etc., and achieve the effect of low production cost, wide application range, and reliable grasping of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

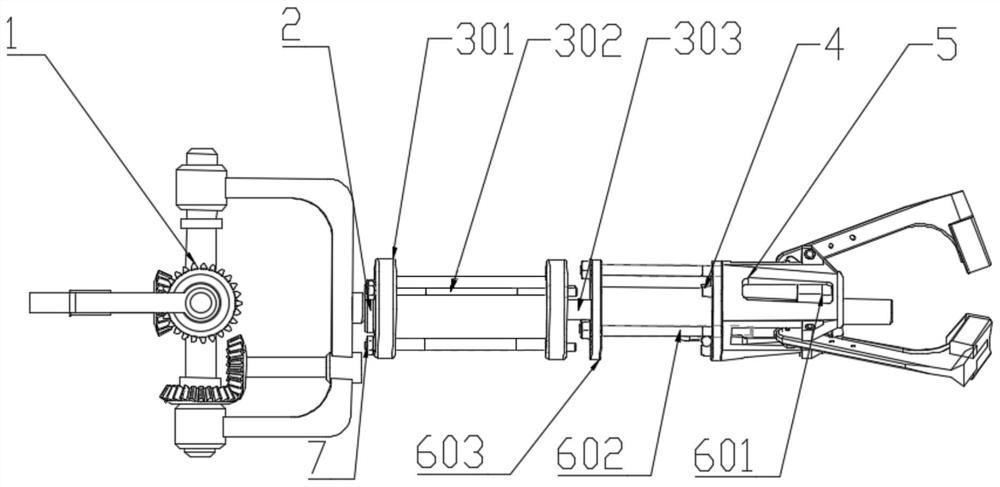

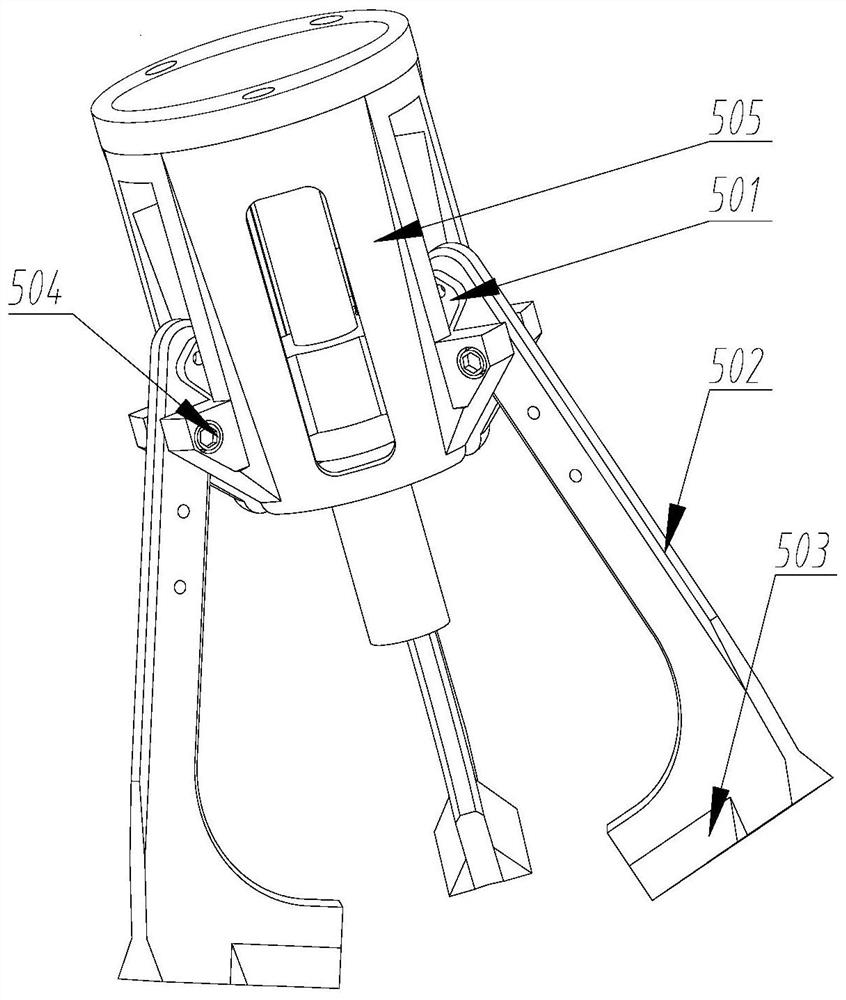

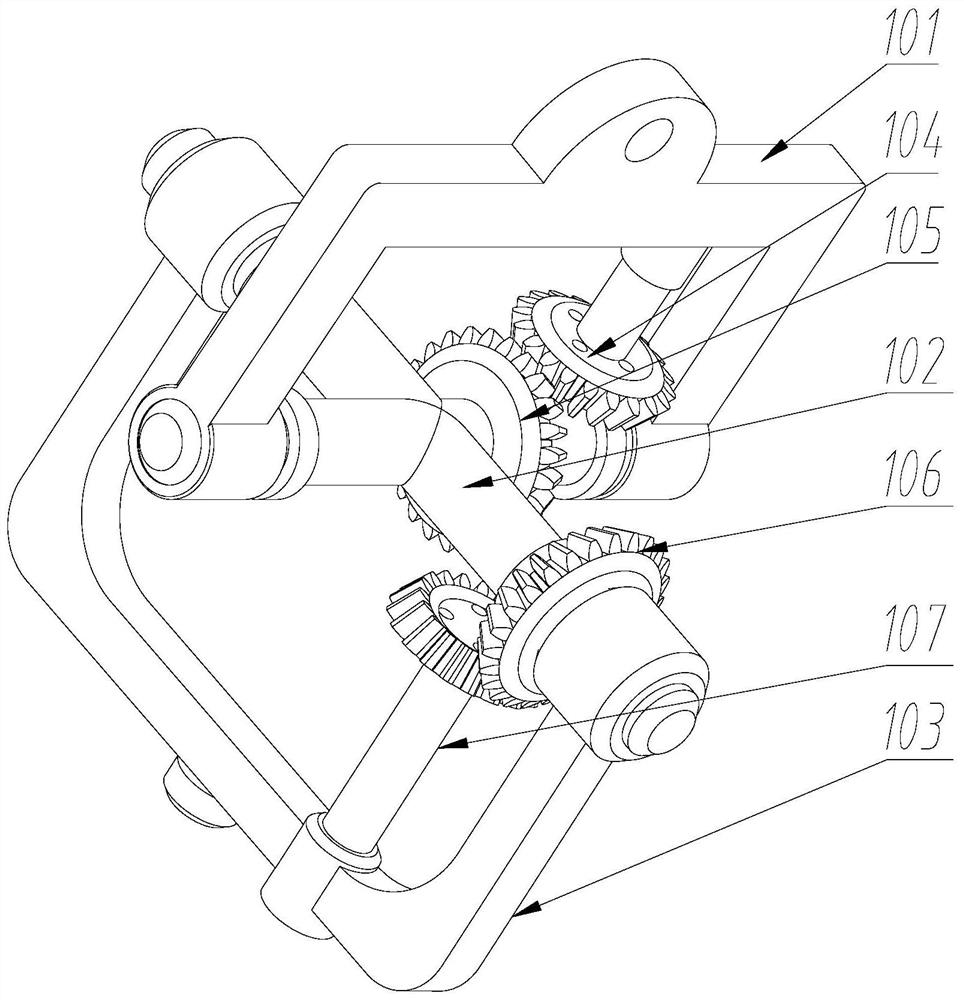

[0023] Embodiment 1, see Figure 1-Figure 3 , a small parts grasping and installing manipulator, comprising: a wrist mechanism 1, a first cylinder 3, a second cylinder 6 and a hand grip 5, wherein: the wrist mechanism 1 includes a first curved connecting rod 101, a cross connecting rod 102, The second curved connecting rod 103, the first bevel gear 104, the second bevel gear 105, the third bevel gear 106 and the fourth bevel gear 107 are convenient for adjusting the clamping angle and clamping parts in various positions. A curved connecting rod 101 is rotatably connected to the end of the cross-shaped connecting rod 102, the second curved connecting rod 103 is rotatably connected to the end of the cross-shaped connecting rod 102, and the first curved connecting rod 101 is provided with a The cylindrical groove installed by the first bevel gear 104 is used for fixedly connecting the first bevel gear 104, and the second curved connecting rod 103 is provided with a cylindrical gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com