Discharge chute bottom plate concrete truss track form drawing construction device

A construction device and a technology for a concrete truss, which is applied in the field of a truss track cantilevered bearing-loading formwork construction device, can solve the problems of inability to turn around, affect economic benefits, and high rail costs, and ensure concrete surface quality, beautiful appearance, and structural integrity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

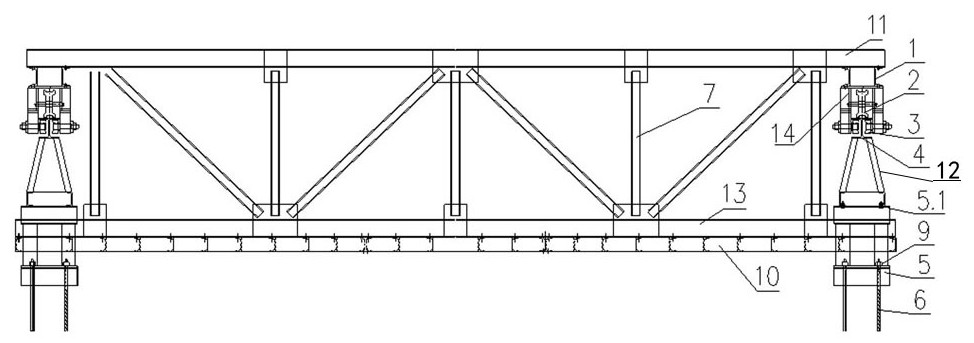

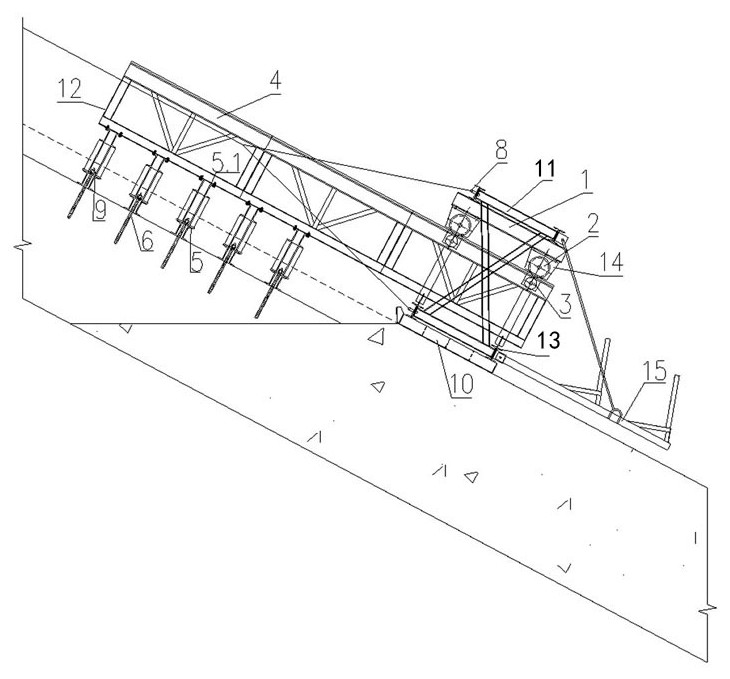

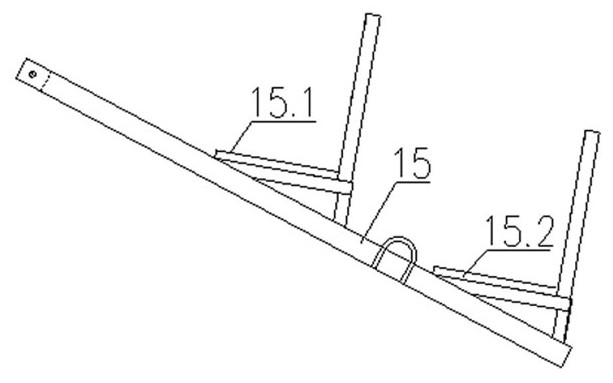

[0018] Track trusses 12 are installed along both sides of the chute, and its upper end is connected with the bottom surface of the track 4, and its lower end is connected with the track cushion 5. The track cushion 5 is connected and fixed with the solidified concrete through the anchor screw 6 and the nut 9, the two ends of the upper beam 11 of the die truss 7 are connected with the beam 1, the lower beam 13 is connected with the panel 10, and the lower end of the beam 1 is connected with the side plates 14 Connection, the walking wheel 2 on the side plate is located on the top of the track 4, the buckle wheel 3 on the side plate is located on the side of the track 4, the die truss 7 is suspended on the two tracks 4, and the track pedestal 5 ensures the back-to-back double The top surface of the upper flange plate of the channel steel connector 5.1 is at least 5 cm higher than the lower beam 13 of the die truss 7 . The lug plate 8 of the die truss 7 is connected with the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com