A pilot hole reaming tbm for inclined shaft and its construction method

A technology for inclined shafts and pilot tunnels, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of low construction efficiency of inclined shafts, improve the stability of cutting and step change, reduce potential safety hazards, and improve construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

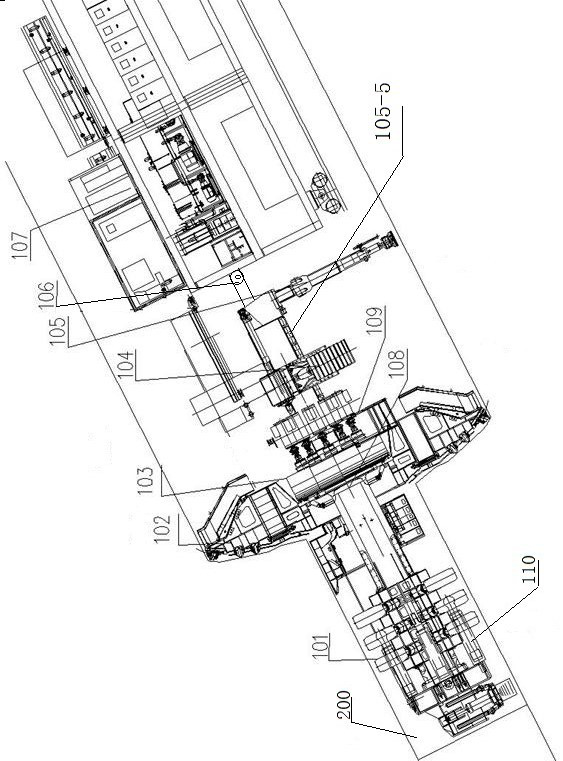

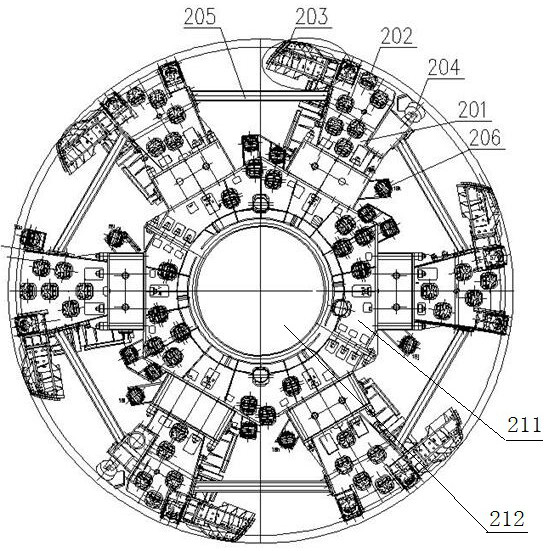

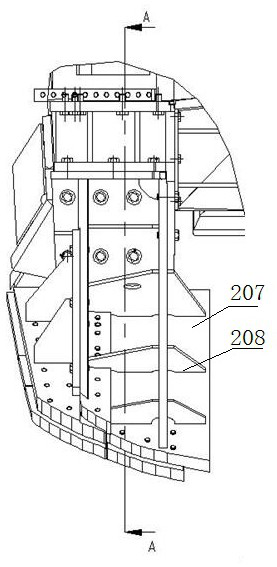

[0032] Embodiment 3: A construction method for a TBM with a pilot hole reaming for an inclined shaft as described in Embodiment 2, the steps are as follows: S1. Align the pilot hole support shoe 101 with the pilot hole 200 and tighten it on the inner wall of the pilot hole , to provide stable support for the TBM; when the TBM is excavating rock, the conical expanding cutterhead 102 rotates, and under the action of the propulsion force, the hob on the conical expanding cutterhead 102 penetrates into the rock to break the rock. During TBM rock-breaking excavation, the over-excavation hob part 204 of the conical expanding cutter head 102 stretches out to excavate the rock formations around the pilot tunnel in advance, and then the hobs on the conical expanding cutter head 102 excavate the surrounding rock formations of the pilot tunnel. The rock formation is excavated layer by layer again, and the slag generated during the excavation process enters the pilot tunnel under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com