Visual identification and separation system for belt conveyor in underground coal mine

A belt conveyor and visual recognition technology, applied in sorting and other directions, can solve the problems of increasing coal production cost, large workload, low efficiency, etc., and achieve the effect of improving sorting work efficiency, low cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

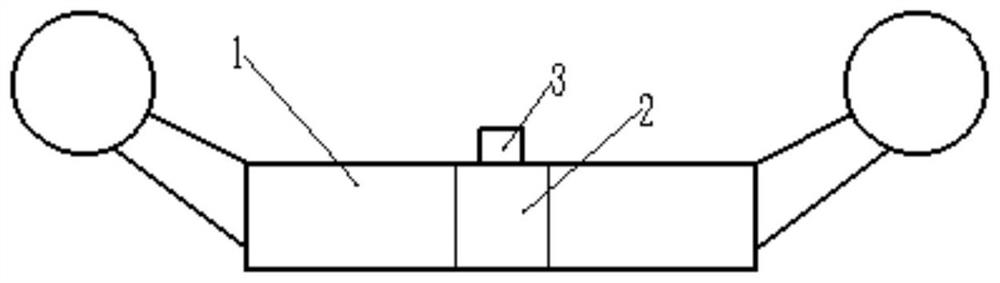

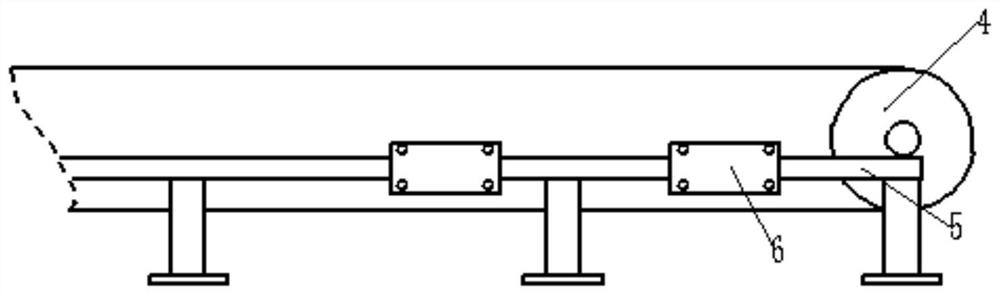

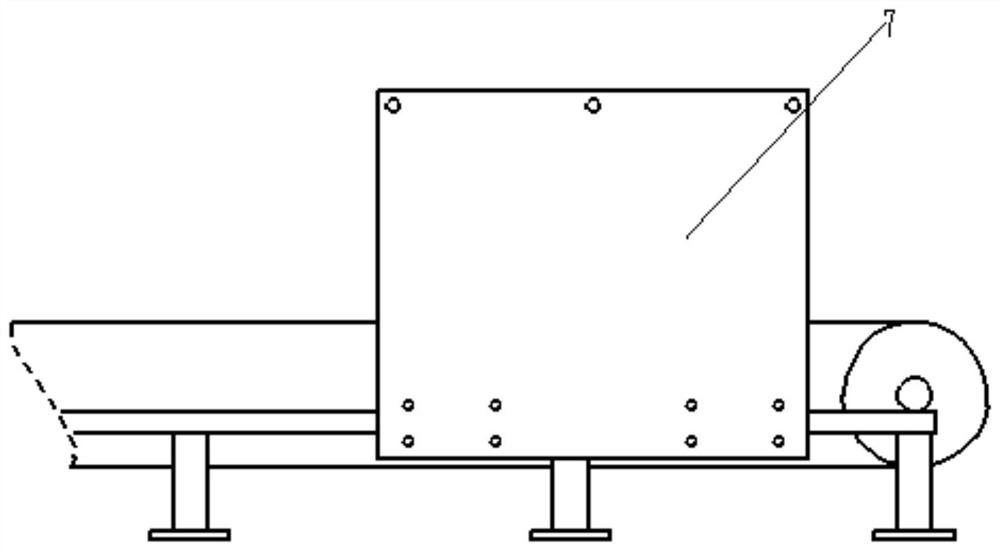

[0023] Such as Figure 1 to Figure 7 As shown, the present invention provides a visual identification and separation system for underground belt conveyors in coal mines, wherein the installation bracket 6 is fixed on the intermediate frame 5 at the outlet end of the belt conveyor by welding, and the support baffle 7 is connected to the installation bracket 6 by bolts. The connection is fixed, the second image acquisition module 9 and the lighting module 10 are fixed on the support top plate 8 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com