Automatic production line for prefabricated part

A technology of automated production lines and prefabricated components, which is applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., and can solve problems such as reducing the amount of manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

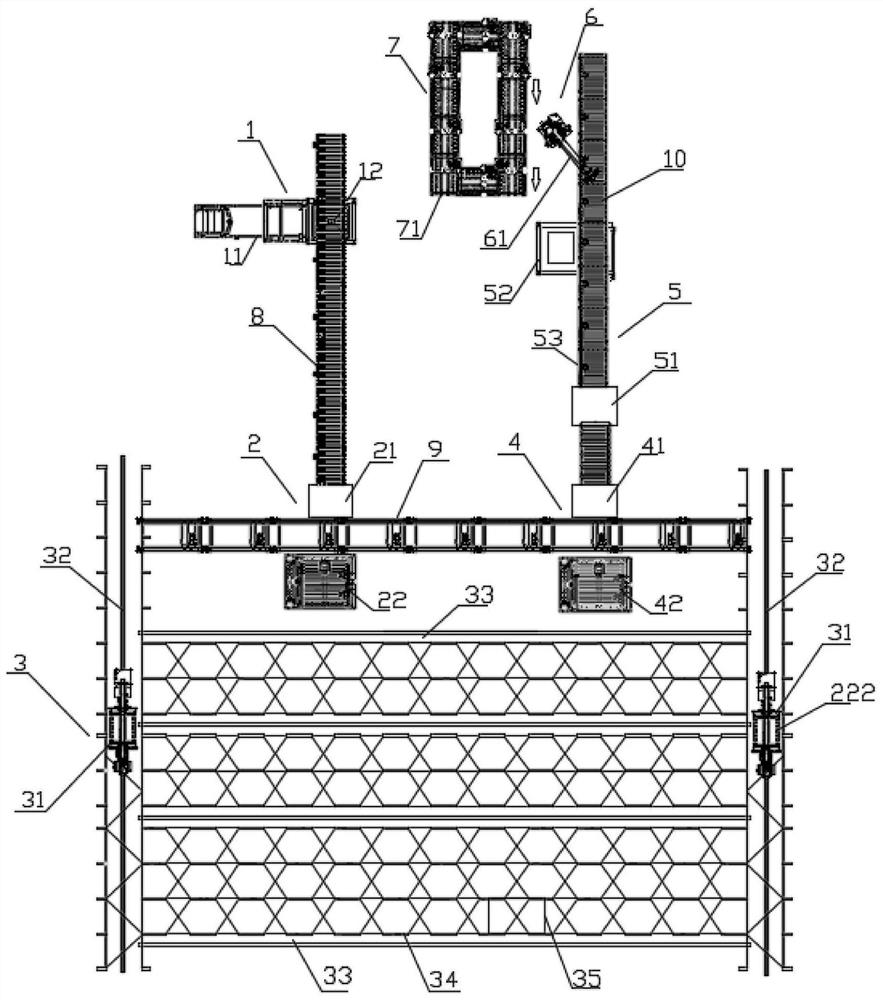

[0016] see figure 1 , a small prefabricated component production line, including a material distribution area 1, a shelf area 2, a maintenance warehouse area 3, a shelf area 4, an automatic mold-taking area for turning over 5, a robot palletizing area 6, and a packaging and forklift area 7. The cloth area 1 is connected to the upper shelf area 2 through the first roller conveyor belt 8;

[0017] The roller-type first conveyor belt 8 and the roller-type third conveyor belt 10 are connected to the maintenance storage area 3 through a chain-type second conveyor belt 9 .

[0018] The distributing area 1 includes a distributing machine 12, a distributing vibrating bed and a mold flow line. The distributing machine 12 is arranged at the front section of the distributing vibrating bed, and the distributing vibrating bed is arranged on the mold circulation line, and the mold circulation line is connected with the first conveyor belt. The distributing machine 12 completes the filling...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap