Single-twisting packaging machine

A packaging machine and kink technology, which is applied in the direction of conveyor belt wrapping, etc., can solve the problems of poor kink packaging effect, affecting packaging sealing, and insufficient technology, so as to avoid deterioration, tight kink and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

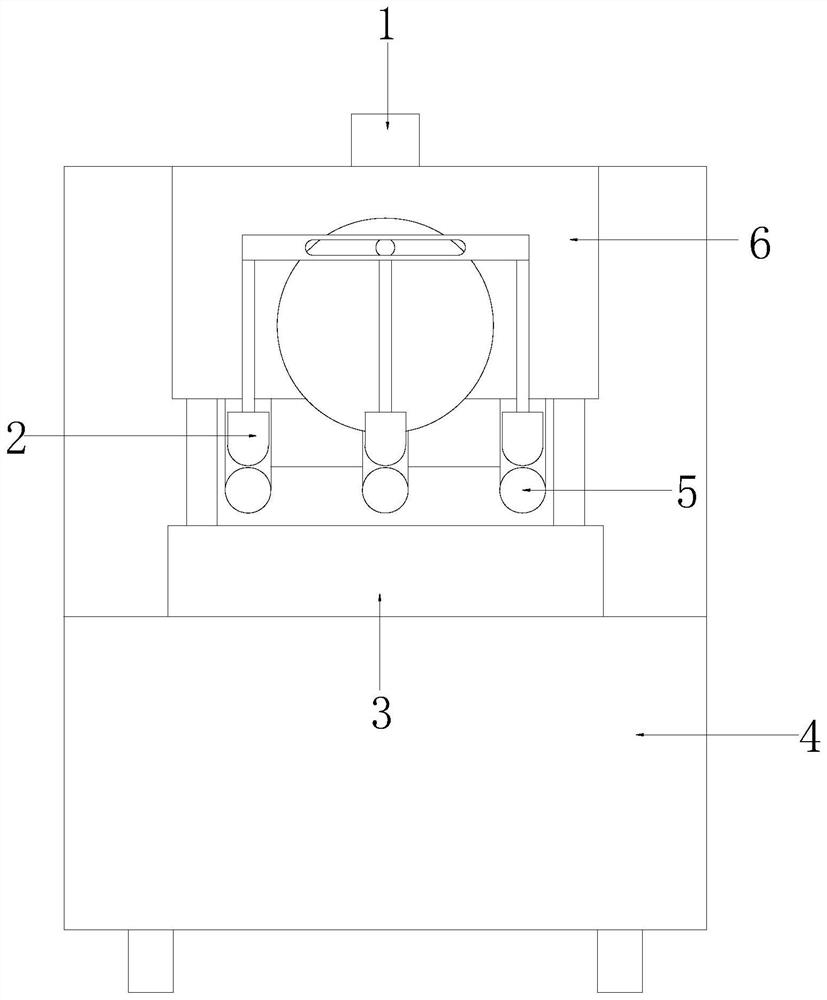

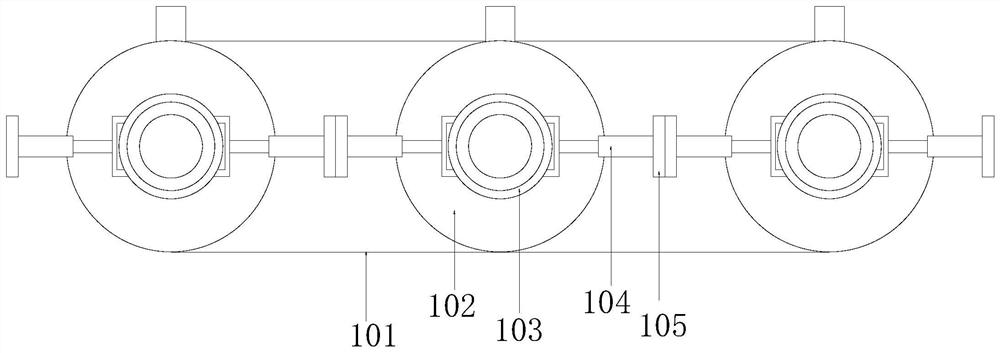

[0031]SeeFigure 1-2 , The present invention provides a technical solution for a single-twist packaging machine: its structure includes a feed tube 1, a grooving device 2, a twist device 3, a packaging body 4, a discharge tube 5, and a hopper 6, and the packaging body 4 works A twisting device 3 is fixed on the table. A notching device 2 is provided above the twisting device 3. The notching device 2 is connected to the outer wall of a hopper 6, which is connected to the packaging machine body 4, and the hopper 6 is provided above Feeding pipe 1, the bottom of the hopper 6 is connected with three discharge pipes arranged side by side, the twisting device 3 includes a conveyor belt 101, a turntable 102, a clamping mechanism 103, a telescopic rod 104, a bracket 105, the turntable 102 There are three and are connected by a conveyor belt 101 for transmission. The upper part of the turntable 102 is provided with a clamping mechanism 103. Both ends of the clamping mechanism 103 are connecte...

Embodiment 2

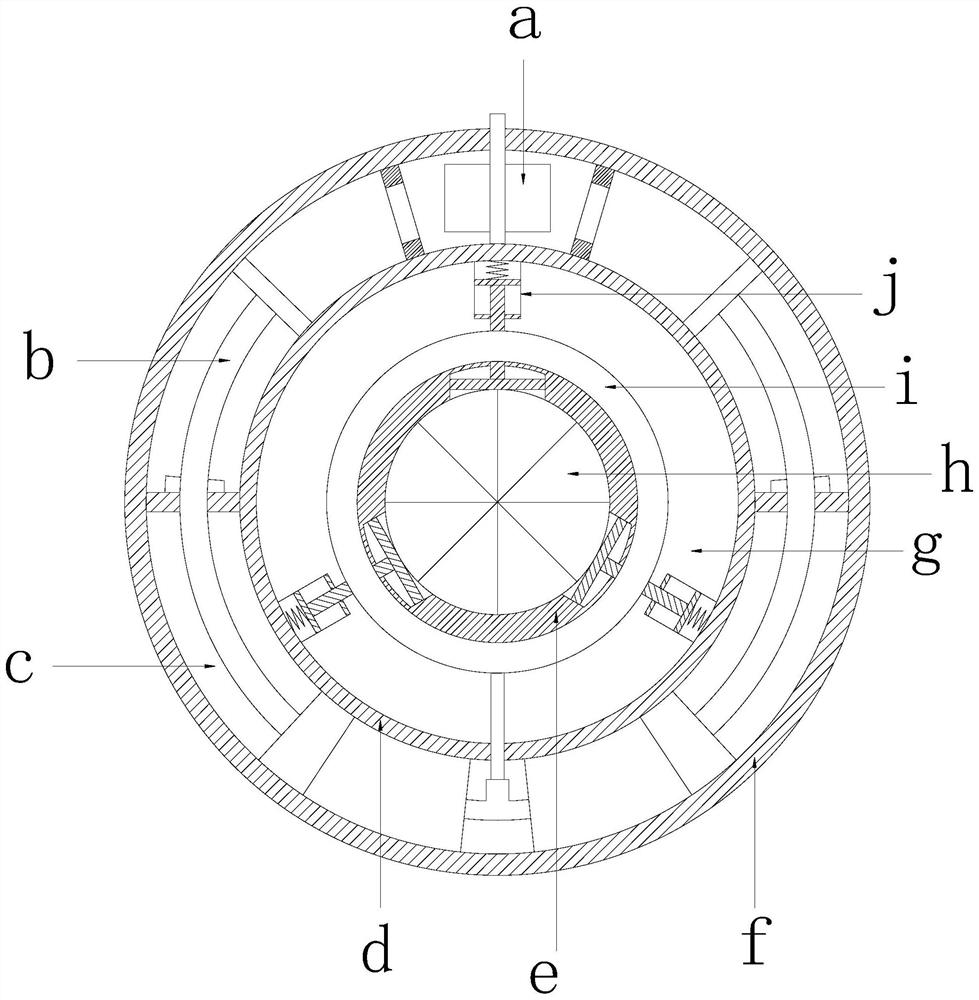

[0038]SeeFigure 4 The air guide assembly b includes an insulating block b1, a limiting block b2, an arc-shaped rod b3, a connecting block b4, an air bag b5, and a magnet. One end of the arc-shaped rod b3 is connected to the insulating block b1, and the other end is connected to the connecting block b4 is connected, the connecting block b4 is connected to the airbag b5, the insulating block b1 and the connecting block b4 are provided with a limiting block b2 connected to the arc-shaped rod b3, and the insulating block b1 is embedded with a magnet.

[0039]The above-mentioned airbag b5 is arranged to discharge air under pressure, reset and inhale, so that air can be filled into the inner pneumatic tire i and the gas in the inner pneumatic tire i can also be pumped away.

[0040]SeeFigure 4 , The first annular cavity c is also provided with a convex tube c1, a limiting ring c2, and a buffer ring c3. The convex tube c1 and the limiting ring c2 are both provided with two pieces and are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com