Production and transportation device for high-pressure sprayer

A technology of high-pressure spraying and transportation devices, applied in the direction of lifting devices, mechanical equipment, lifting frames, etc., can solve the problems of simple structure, low transportation efficiency, inconvenient use, etc., to reduce the trouble of transportation, improve transportation efficiency, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

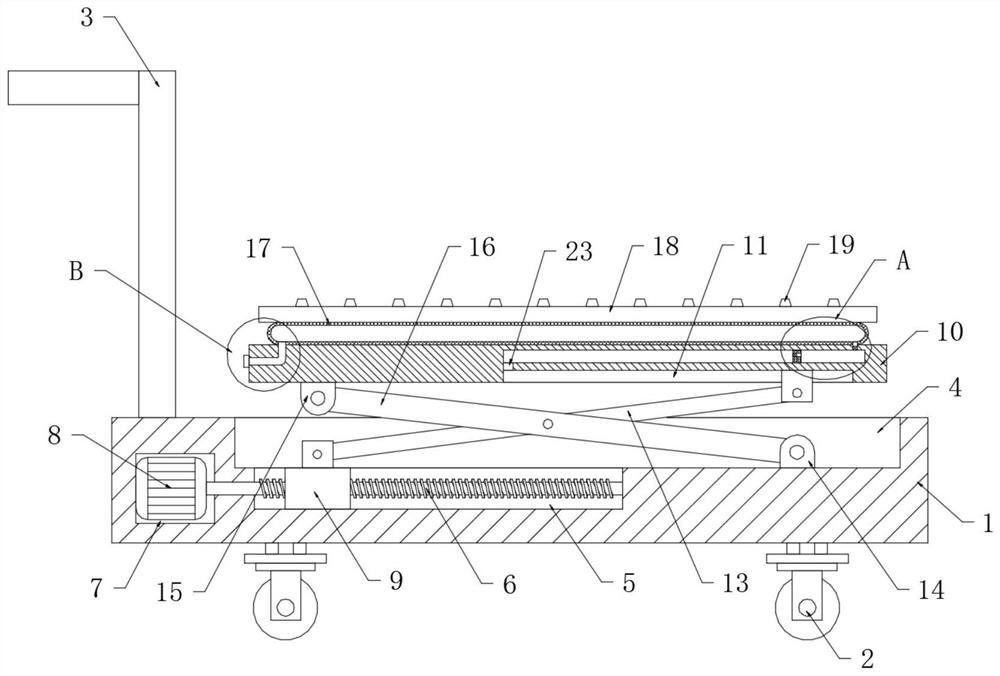

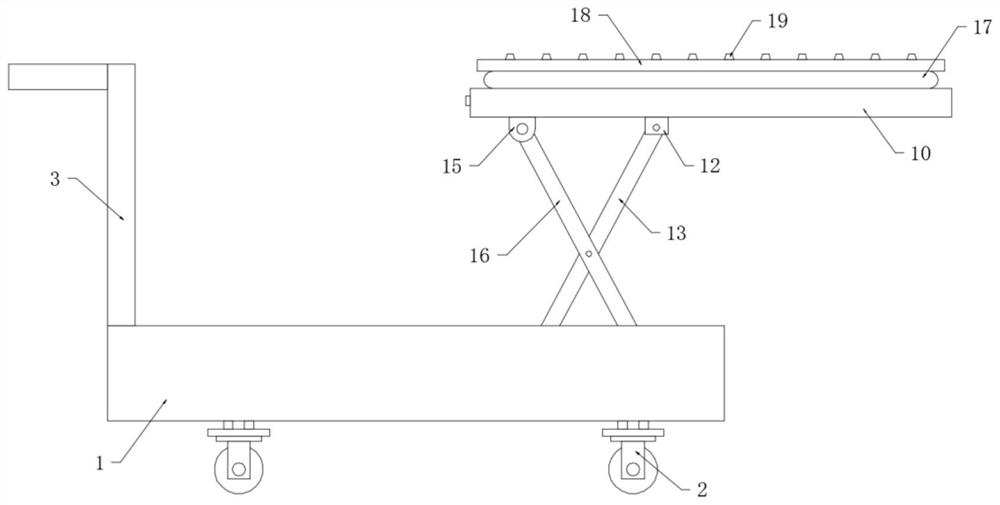

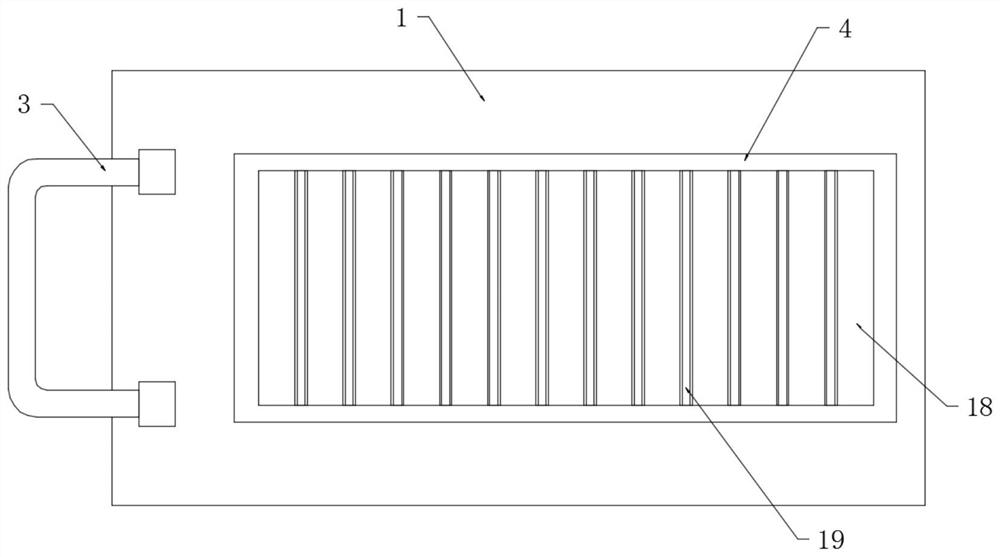

[0028] refer to Figure 1-5 , a production and transportation device for a high-pressure sprayer, including a transportation base 1 and a bearing plate 10, four universal wheels 2 are fixedly connected to the ground of the transportation base 1, and push handles 3 are welded on the side of the upper end surface of the transportation base 1, The end face of the transport base 1 is provided with a groove 4, the bottom of the groove 4 is fixedly connected with a first rotating seat 14 on the side away from the push handle 3, and the bottom of the carrying plate 10 is fixedly connected with a first end close to the push handle 3. Two rotatable seats 15, the first rotatable seat 14 is rotatably connected with a second support rod 16 by a pin shaft, and the end of the second support rod 16 away from the first rotatable seat 14 is rotatably connected with the second rotatable seat 15 by a pin shaft.

[0029] The bottom of the groove 4 is provided with a moving groove 5 close to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com