3D printing device for vacuum glass support

A vacuum glass and 3D printing technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as easy movement, low yield of vacuum glass, and small volume of supports, so as to reduce costs and improve production automation The degree and yield, the effect of solving the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

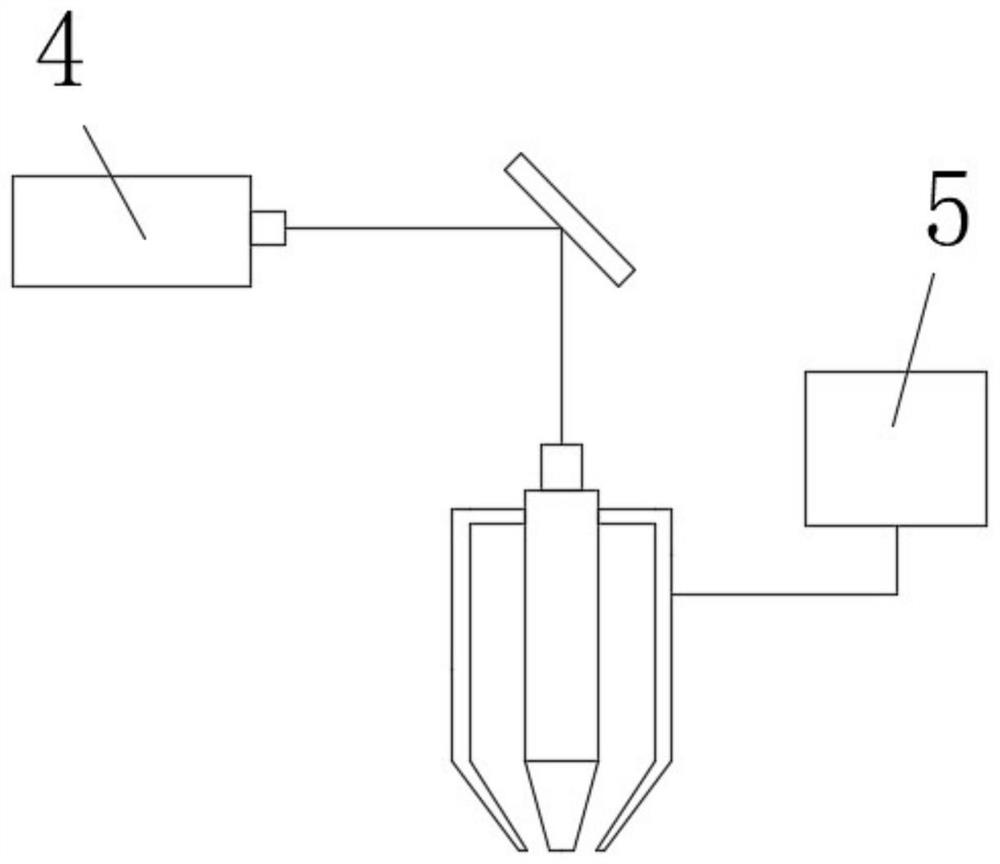

[0027] Example 1: Put low-melting-point glass powder with a melting point of 600 degrees and an average particle size of 20um into the powder feeder of a near-net shape 3D laser printing head; place a rectangular glass of 1010mmx1010mm and a thickness of 6mm on a predetermined position on the working platform , determine the coordinates of the four corners of the glass; the position coordinates of the vacuum glass support and the shape data of the support are input to the trajectory controller, and the printing area of the support is set to 1000mmx1000mm, and the width of the surrounding 10mm is used for vacuum glass edge sealing; the printing point is set to 20mmx20mm chessboard square The intersection point of the grid, the bottom surface of the support is a circle with a diameter of 0.3mm, the height of the support is 0.3mm, and the shape is cylindrical;

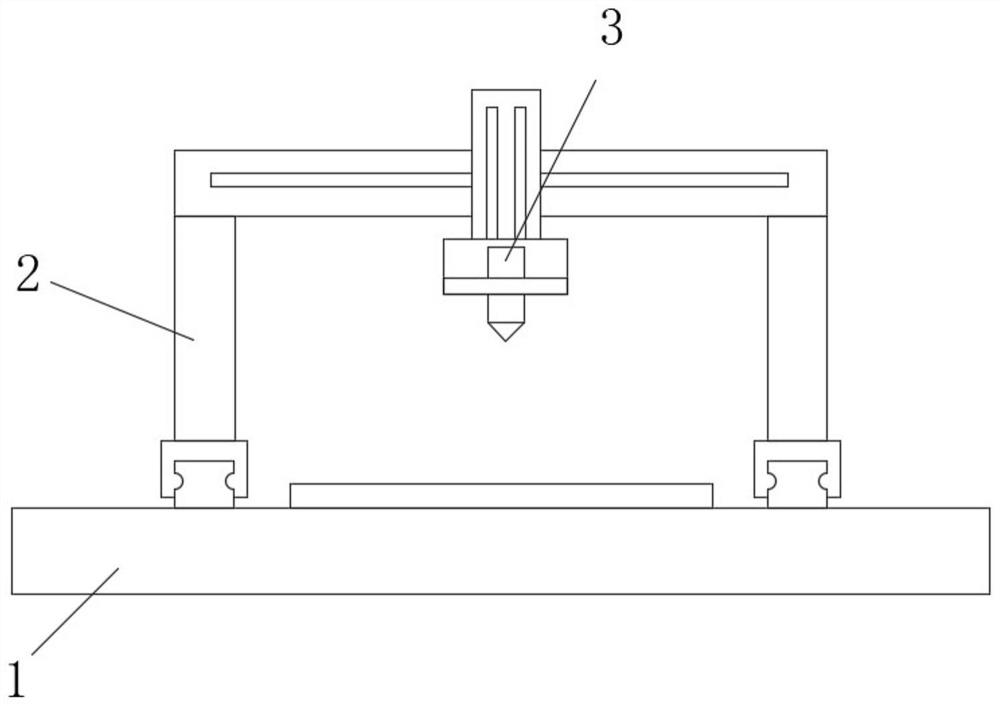

[0028] Start the printing program, the three-dimensional mobile slide 2 moves the near net shape 3D laser printing hea...

Embodiment 2

[0029] Example 2 The low-melting glass powder with a melting point of 600°C and an average particle size of 20um in Example 1 was replaced with a low-melting glass powder with a melting point of 700°C and an average particle size of 20um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap